A Marvel of Engineering

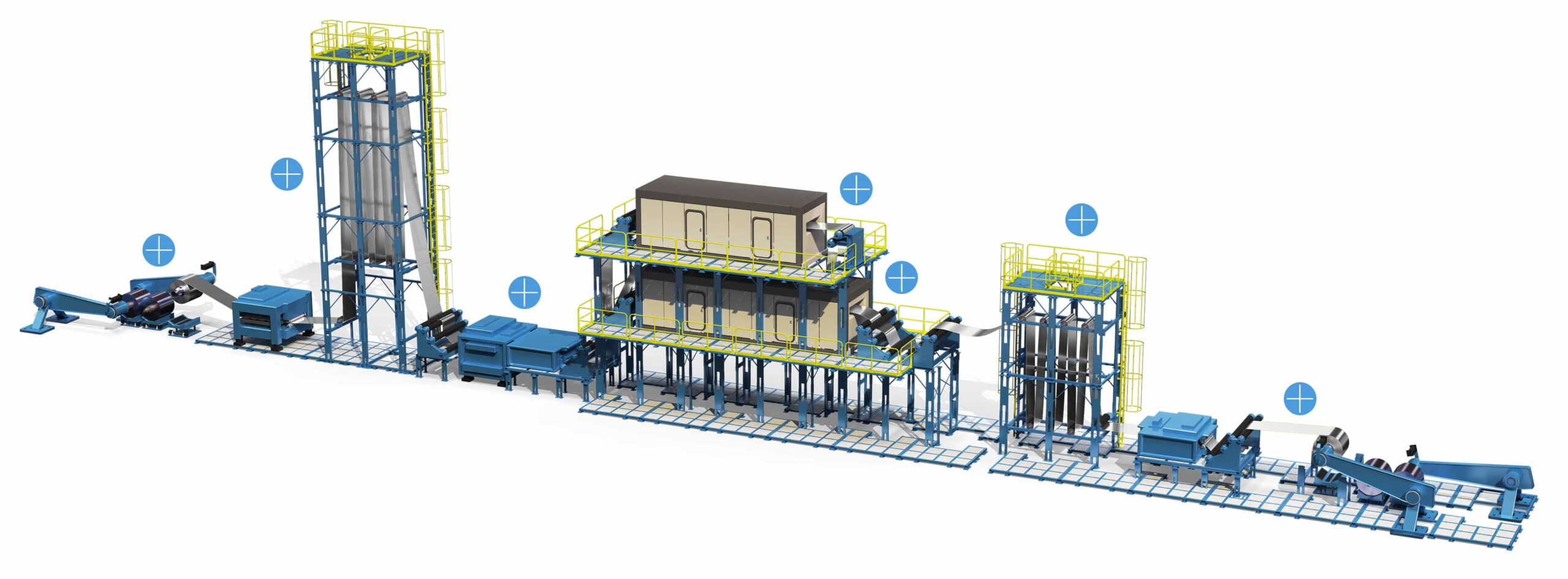

The coil coating process applies coatings and laminates to metal coils in a continuous, automated manner before fabrication. With metal coils up to 72 inches wide and traveling at 700 feet per minute, both sides are cleaned, treated, primed, top-coated, and cured before recoiling for shipment.

Coil coating is known for cost-effectiveness, aesthetics, field performance, and sustainability. It operates as a closed loop system with over 98% VOC capture and conversion to fuel. In the European market, the finished product is referred to as “prepainted” or “precoated” metals or coils.

Click the Image Hotspots to Learn About Our Process