Baseball Stadium

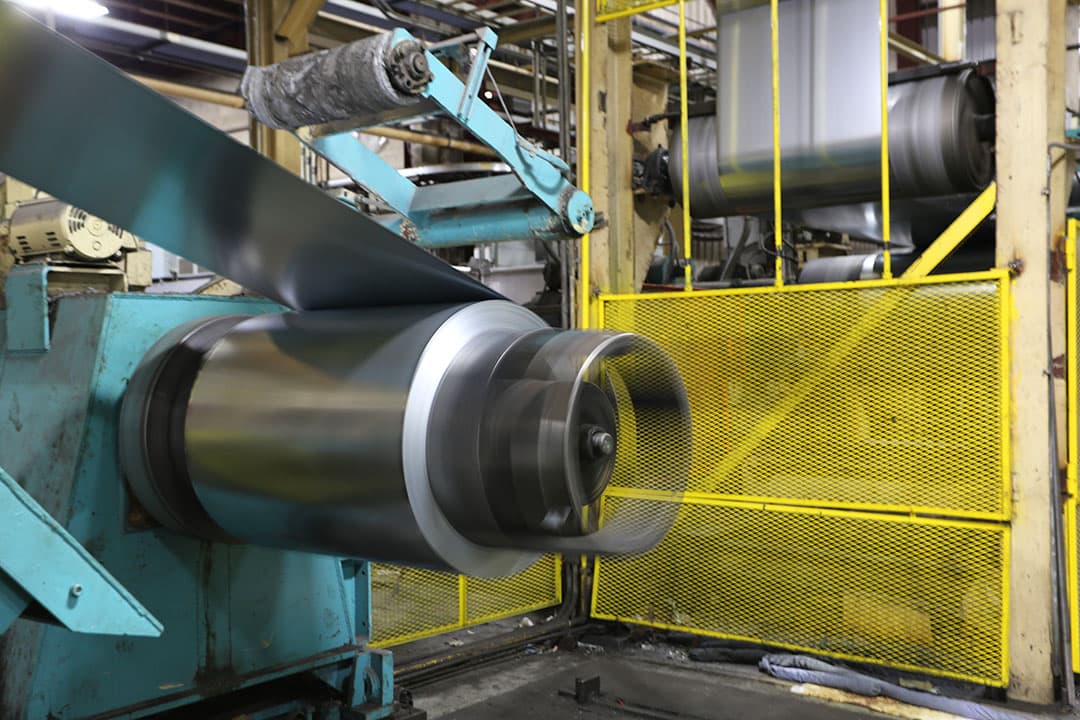

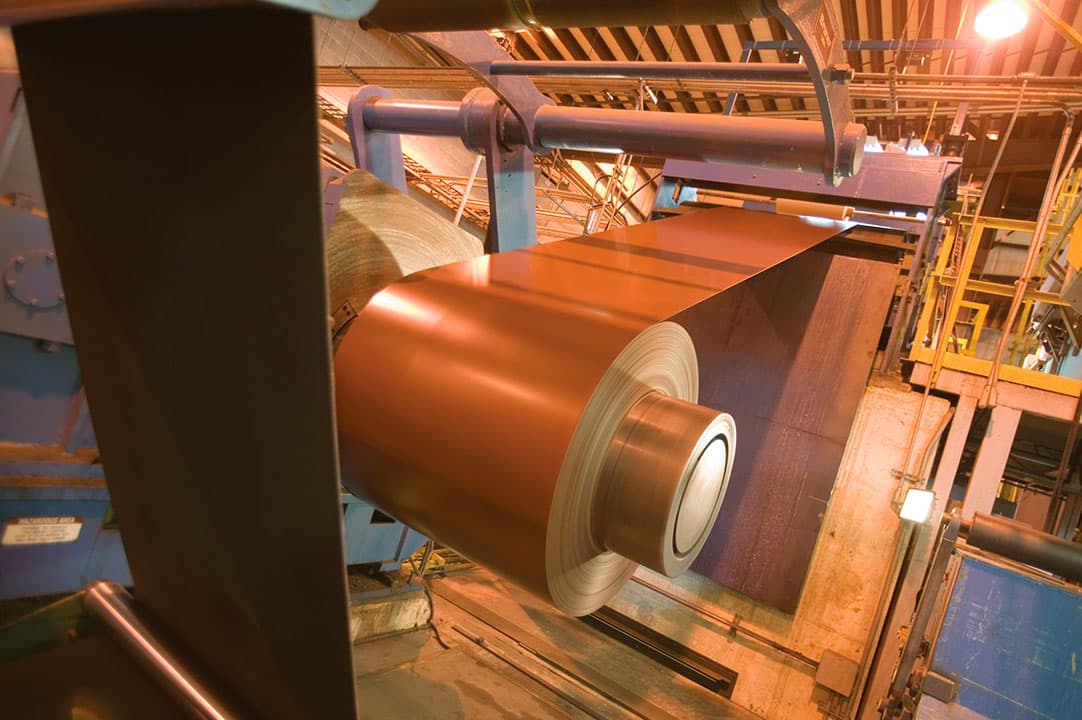

The zero maintenance factor of hot dip galvanized steel and the economic savings it delivers year after year were drivers for this stadium project. Basic paint simply would not do justice to a stadium of this caliber.

AZZ galvanizing protection provides the best game plan

The uniformity of the zinc coating and its aesthetic appeal was an additional complement to the radius roof design, a key feature of this magnificent facility.

All 250 tons of steel including stringers, columns, beams, rail risers and handrails – were hot- dip galvanized and required a 24 – 72 hour turnaround, due to limited storage at the job site. The coating thickness, which exceeds ASTM specifications in this suburban climate, easily ensures the stadium will reach 40—50 years of maintenance-free service life.

It is no coincidence that the university chose hot-dip galvanizing as an integral part of its showcase facility. Built as part of the emergence of the university as a leader in NCAA sports, this attractive stadium is one that alumni and fans can be proud of for years.

Contact Us

Email Signup

Sign up to receive the latest news from AZZ