Surface Prep

The key to ensuring a quality, consistent finish

Surface preparation is critical to obtaining a high-quality finish, whether it be powder or wet coating. AZZ has extensive expertise in sandblasting, which efficiently and effectively smooths rough edges and repairs surface blemishes. Our sandblasting capabilities extend to parts as large as 40 feet in length, and our quality control measures, in accordance with our ISO 9001 certification, ensure an optimal surface for comprehensive and consistent coating.

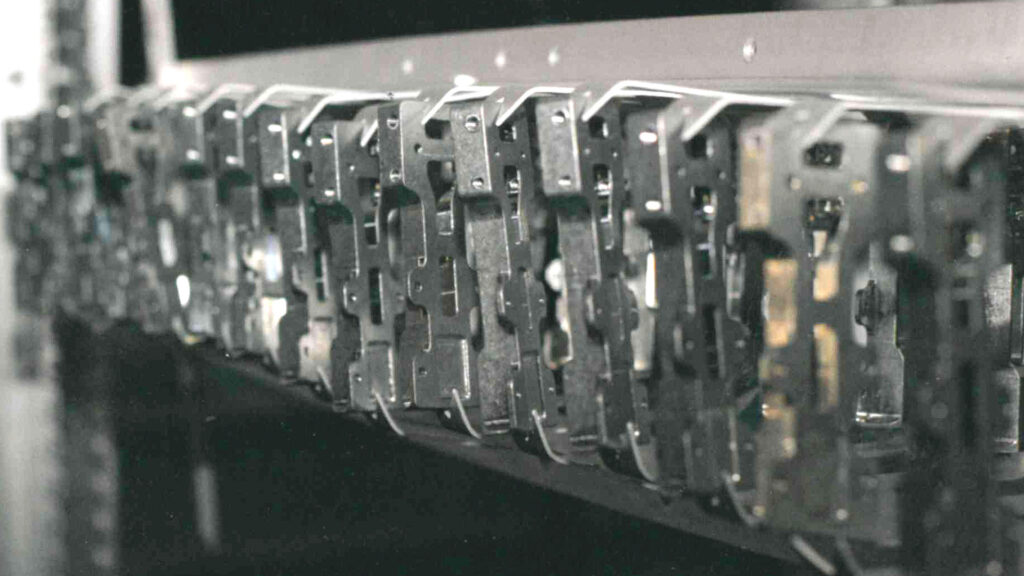

Assuring proper grounding and consistent coverage

One aspect of our quality control is daily stripping of the hooks, racks, fixtures and steel parts used in our operations. The process ensures the proper grounding and consistent coverage of the parts to be coated the following day. The stripping of organic paint and powder coating from parts and fixtures is a service we also offer to our customers.

Duplex Coating

Optimal protection achieved through the synergies created by combining hot-dip galvanizing and powder or wet coating

Powder Coating

Durable coatings which provide long-lasting corrosion protection in an array of colors and textures

Wet Coating

Solvent-based paint formulations in an array of colors wet blasted for consistent coverage and corrosion protection