Metal Coatings

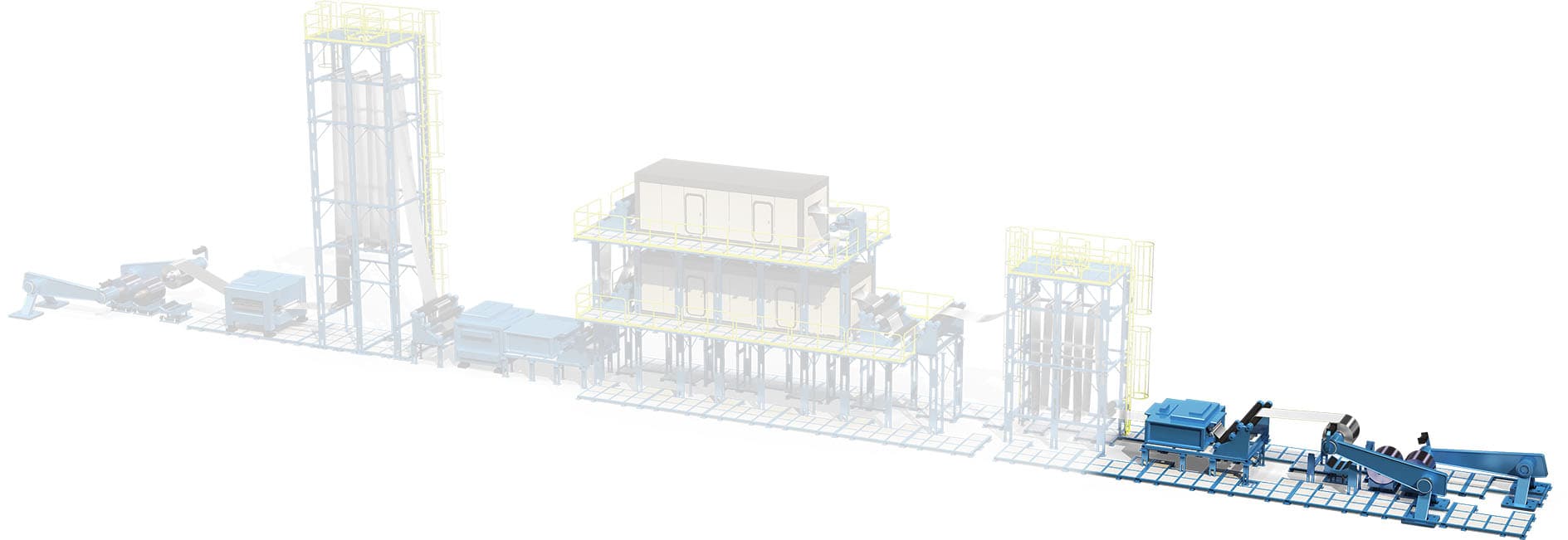

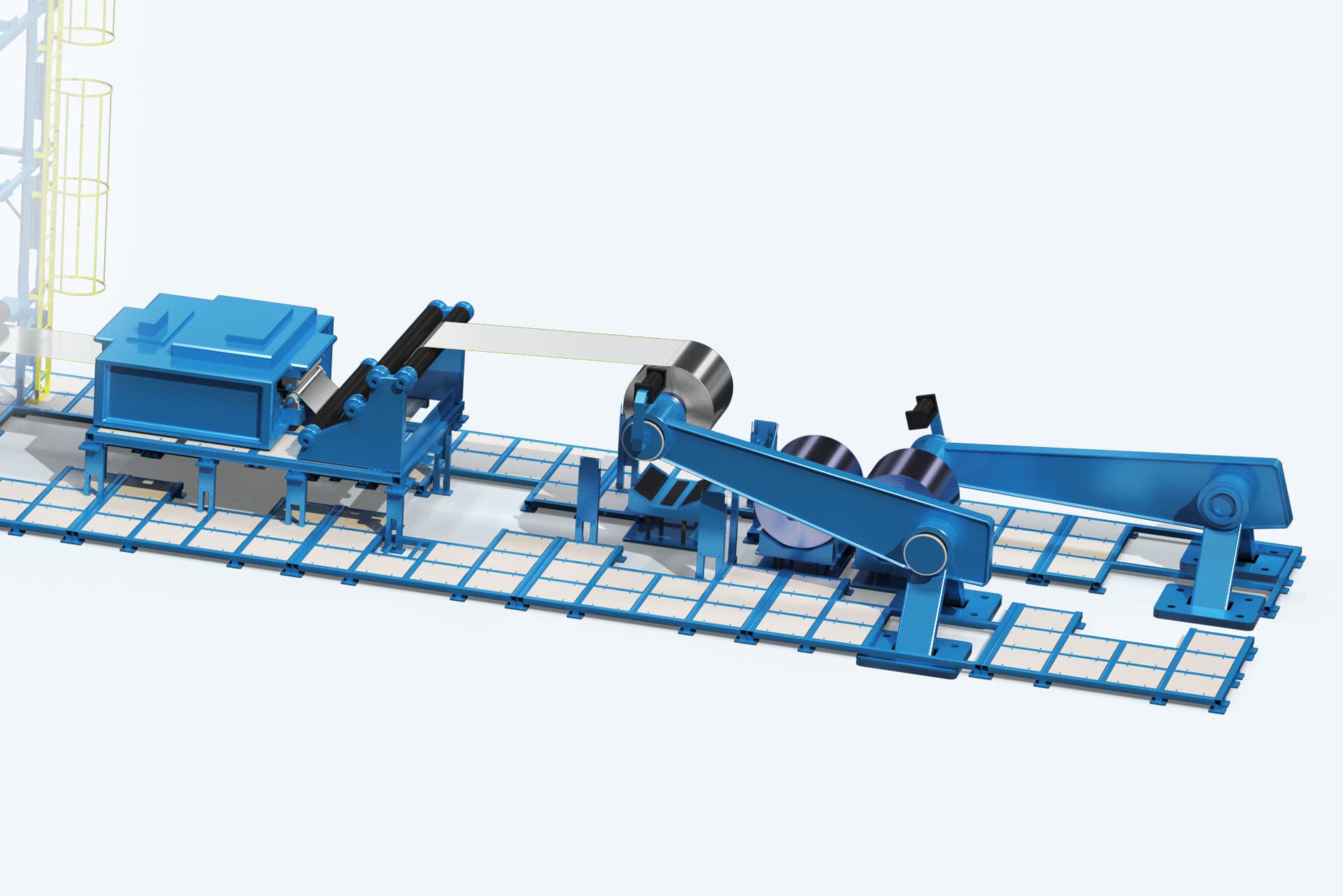

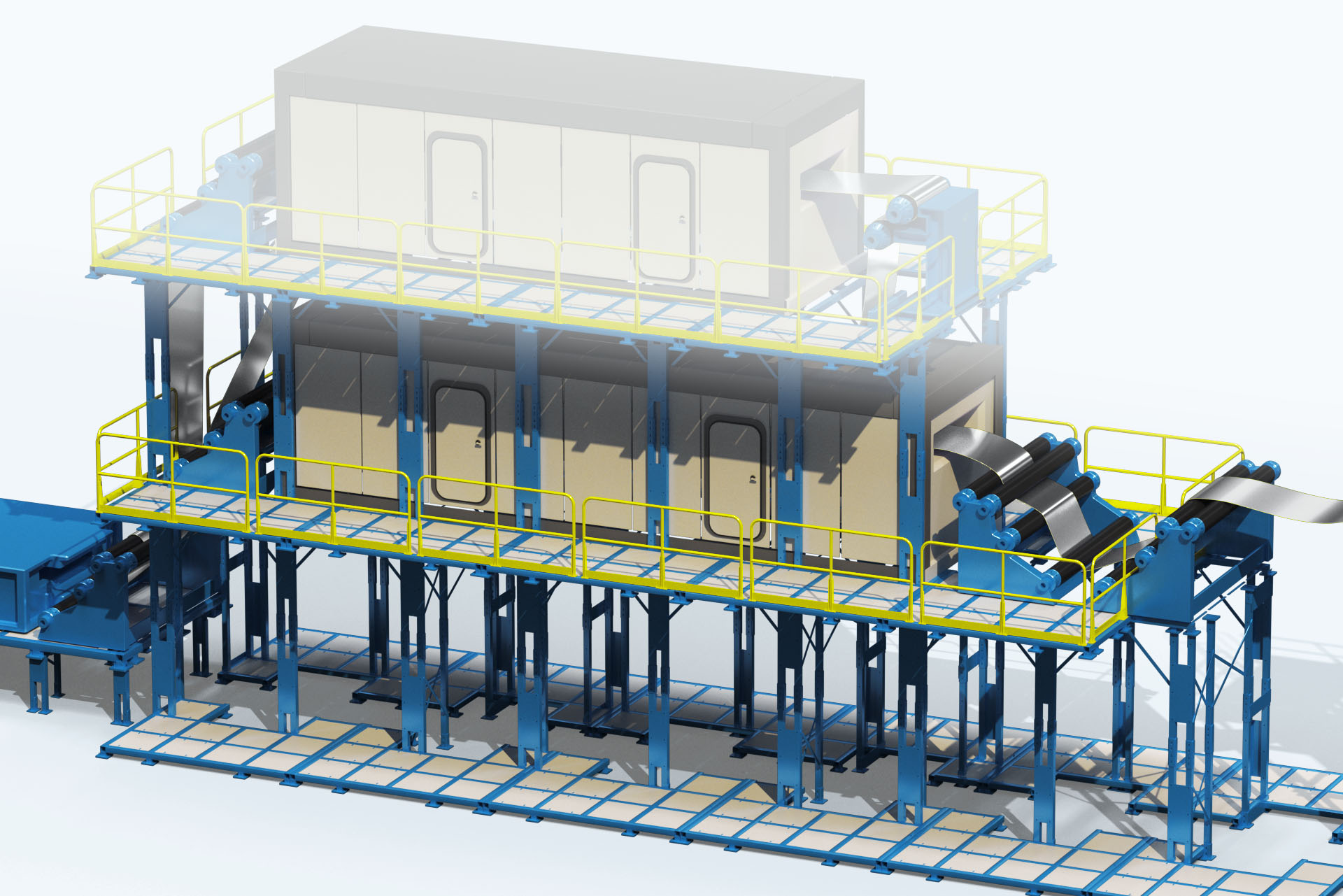

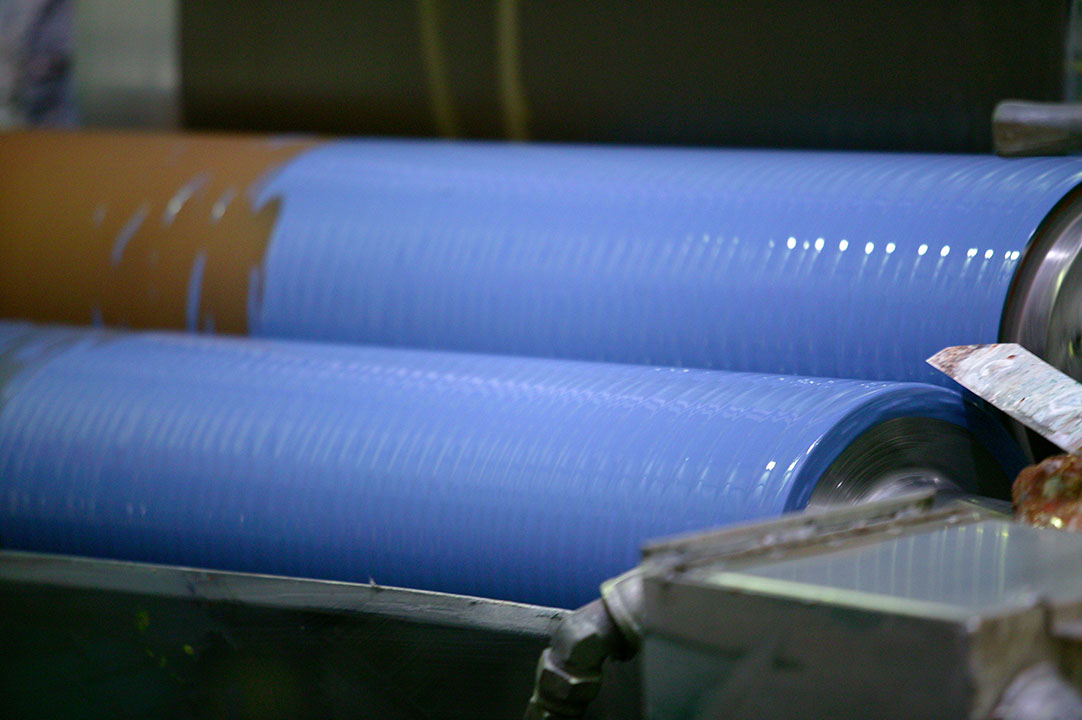

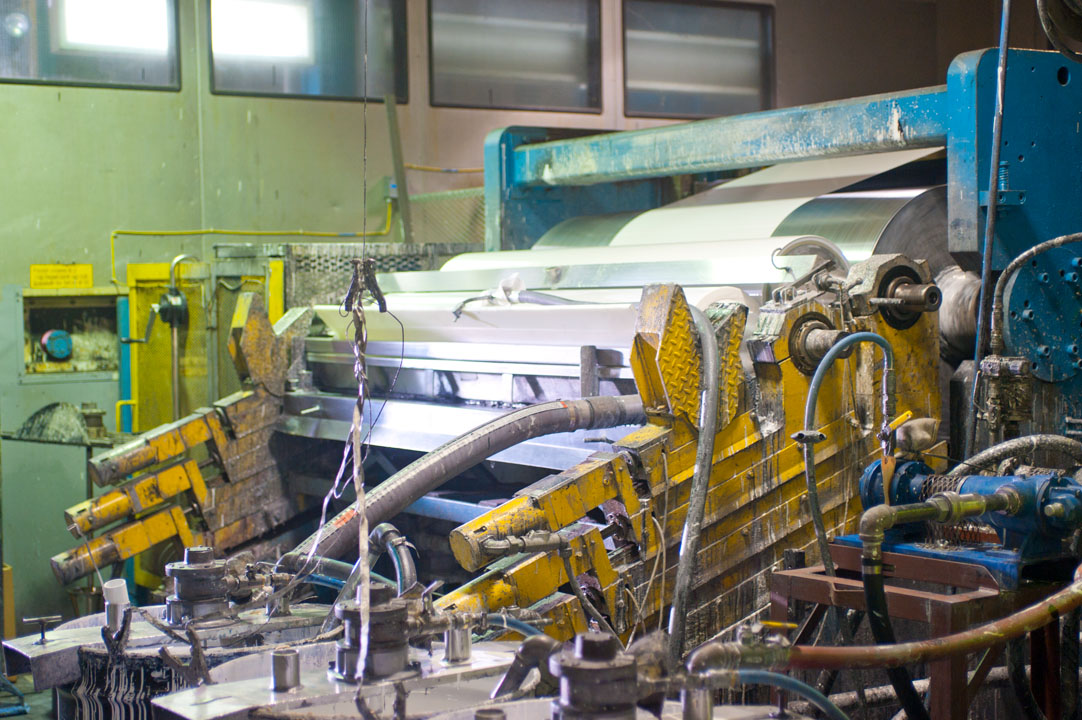

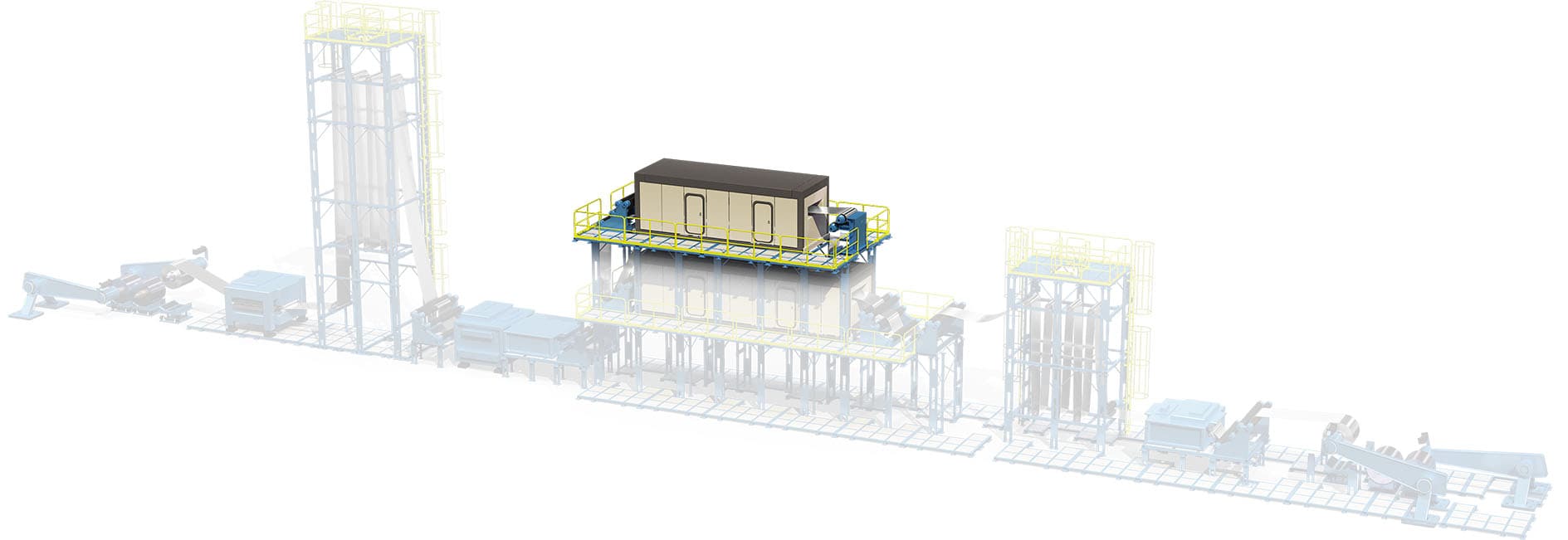

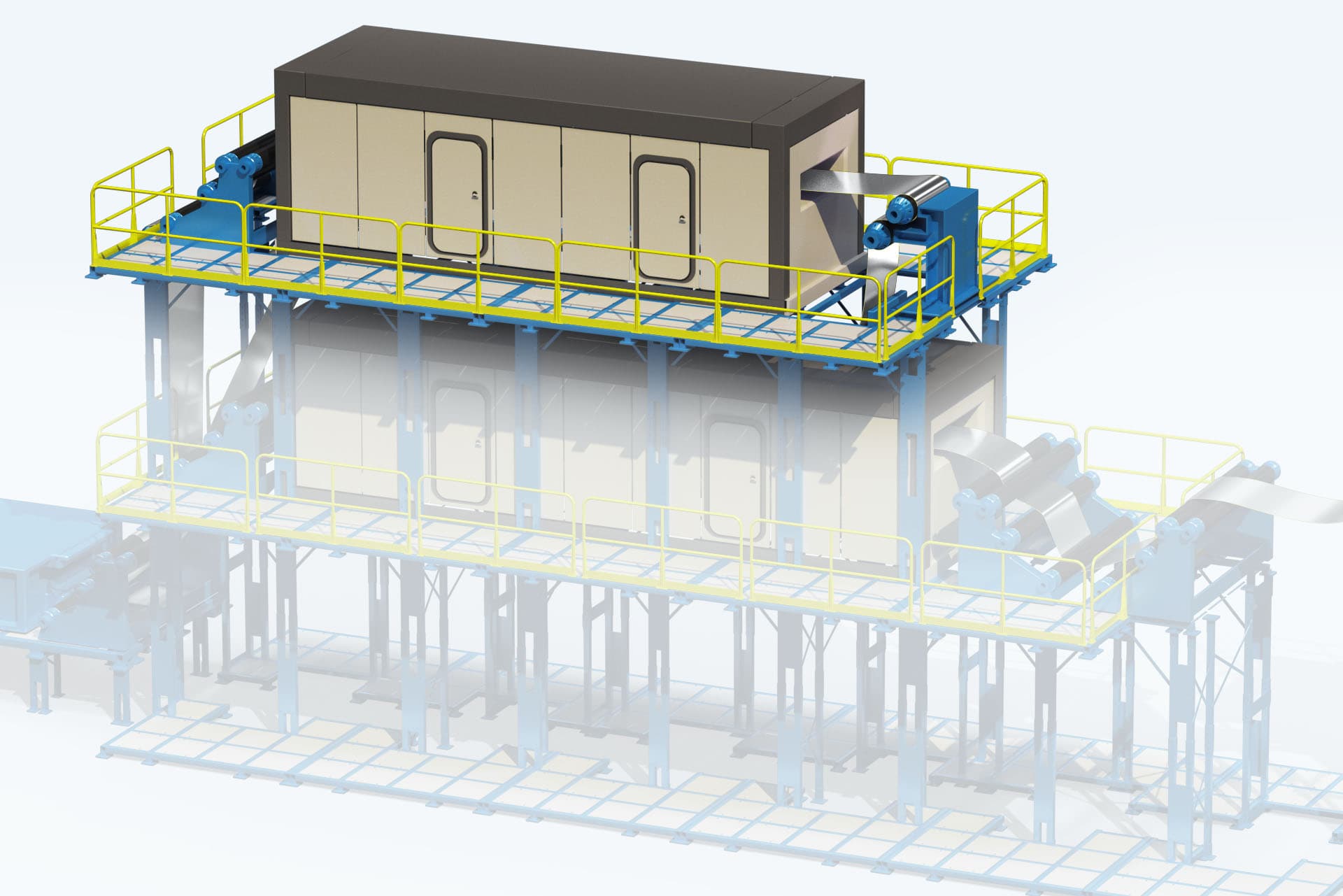

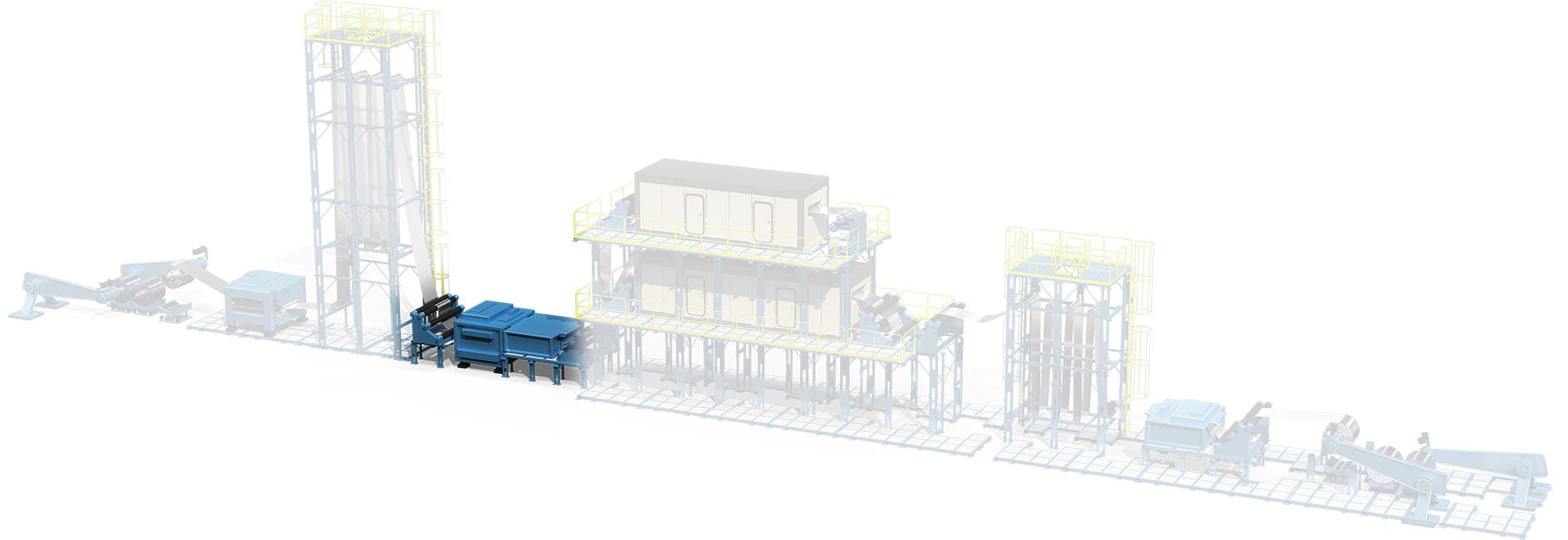

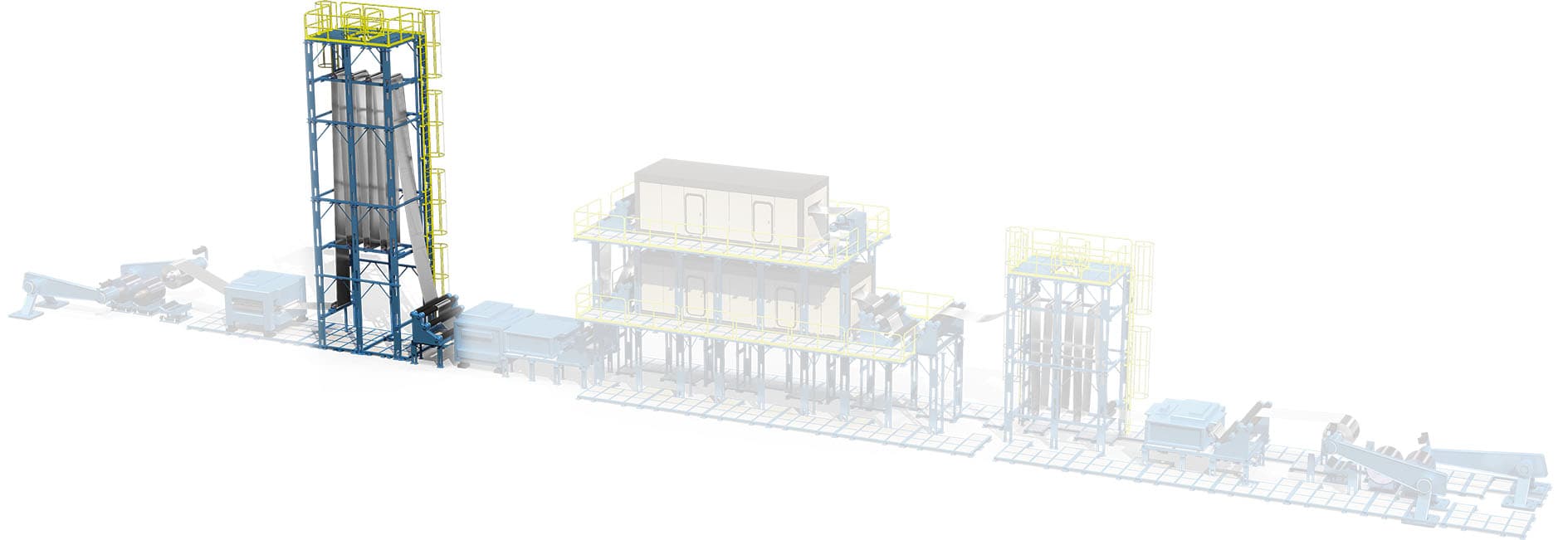

Comprehensive metal coating capabilities for stronger and sustainable infrastructure

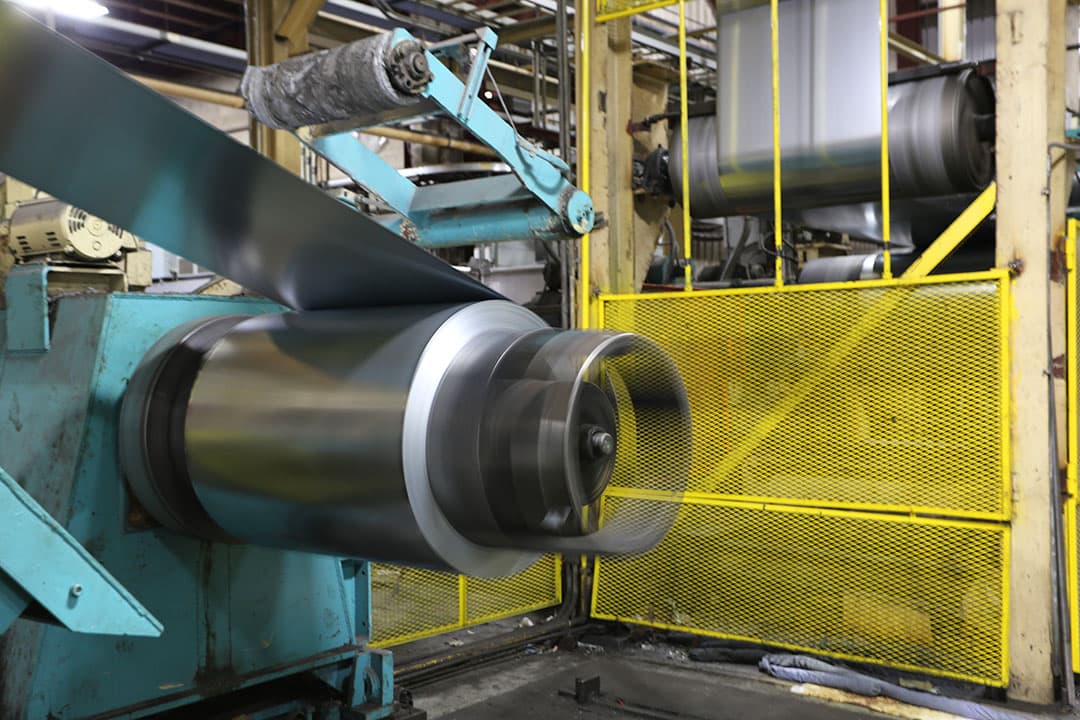

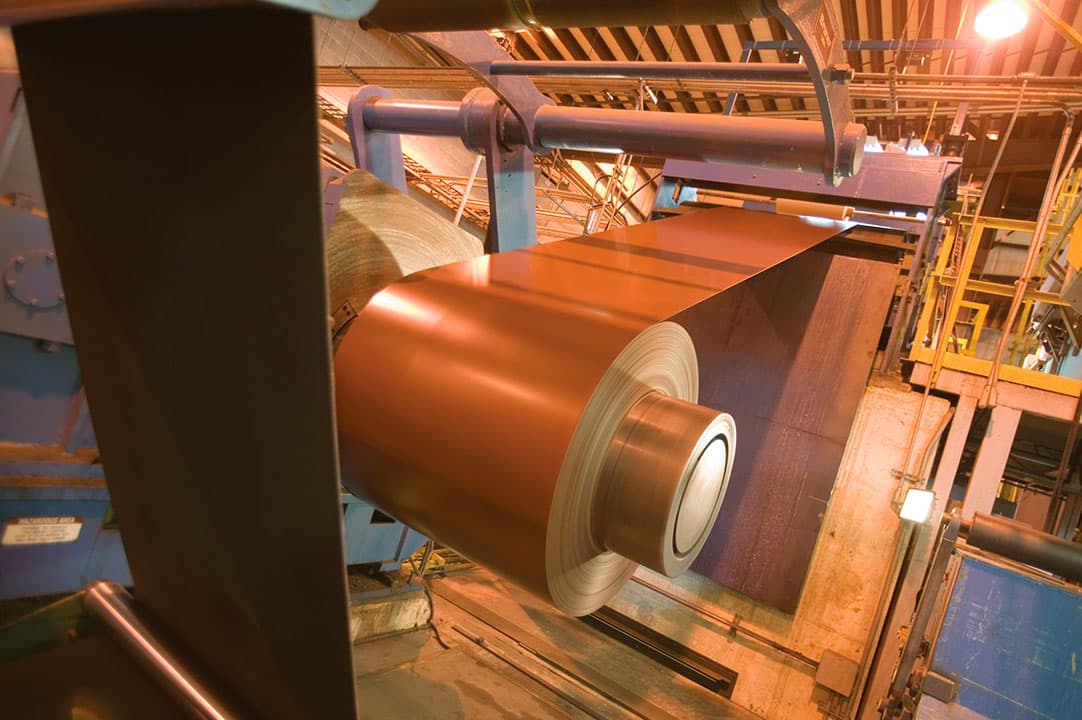

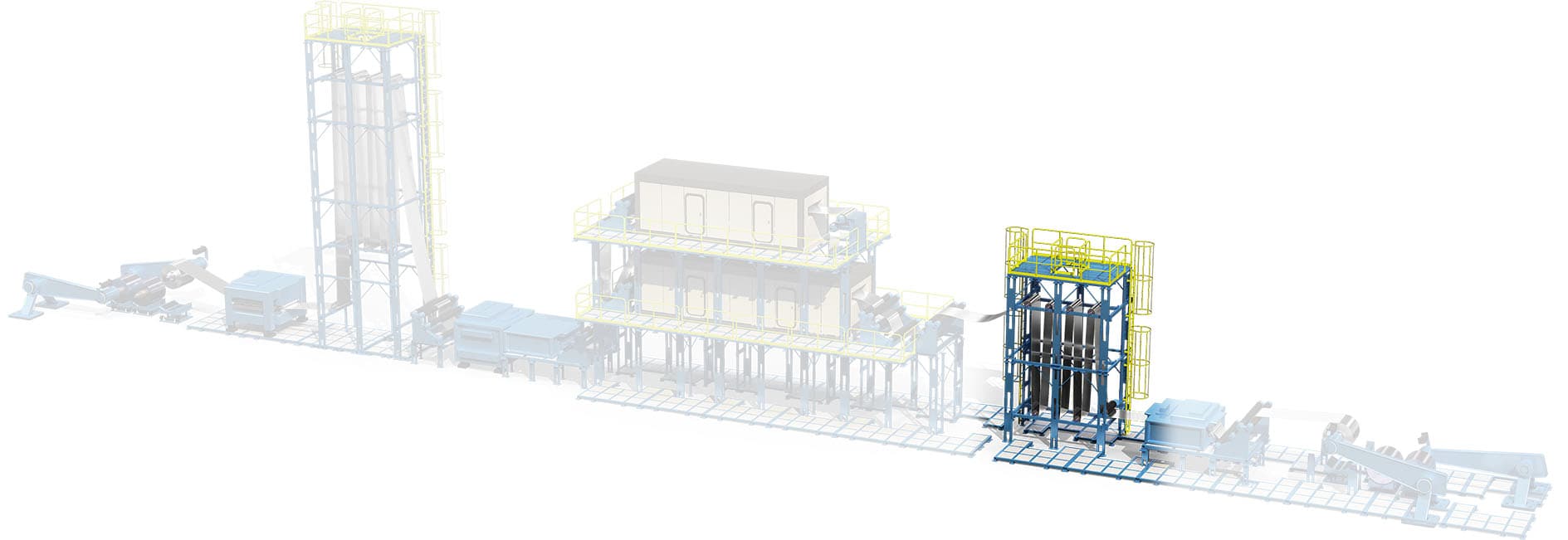

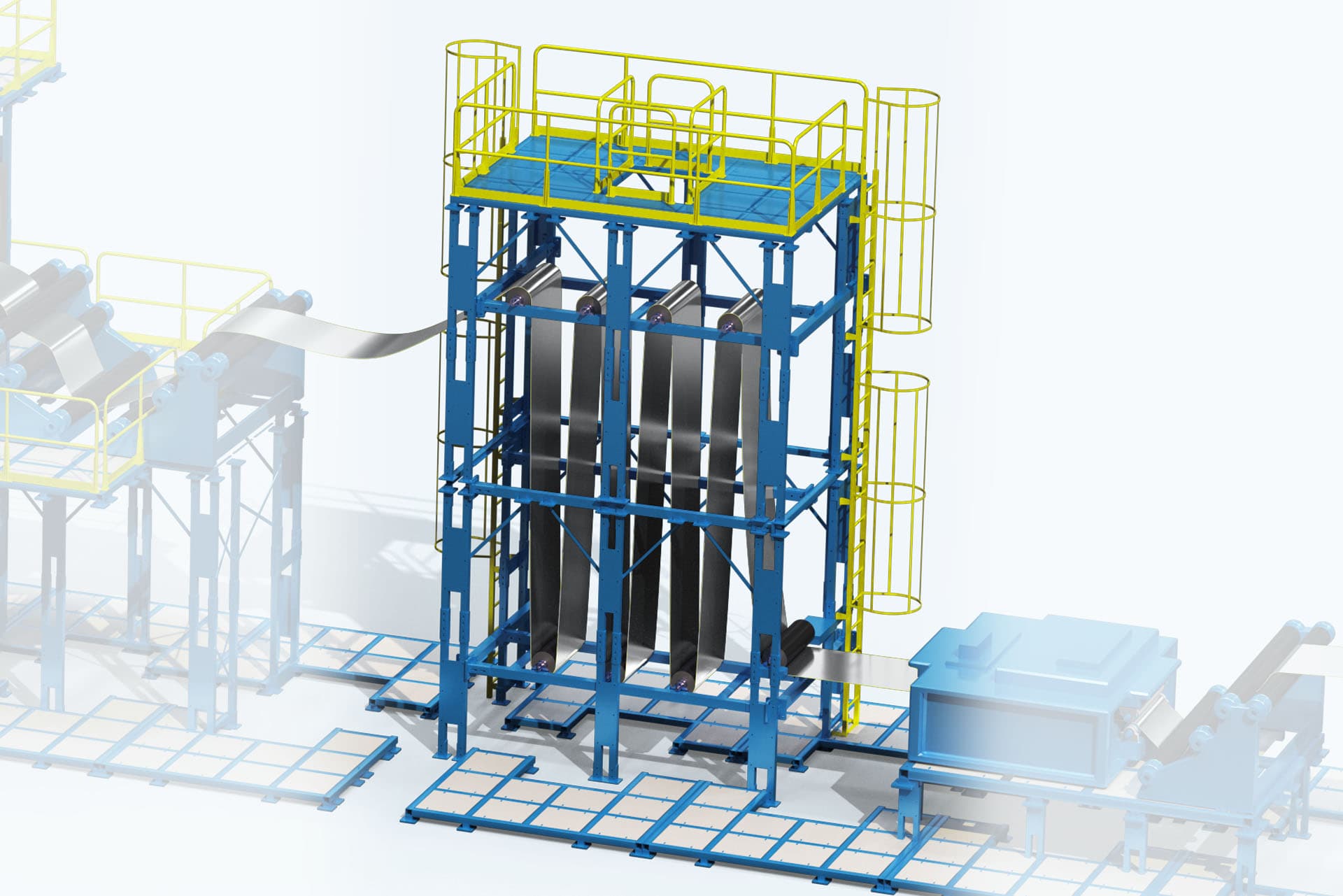

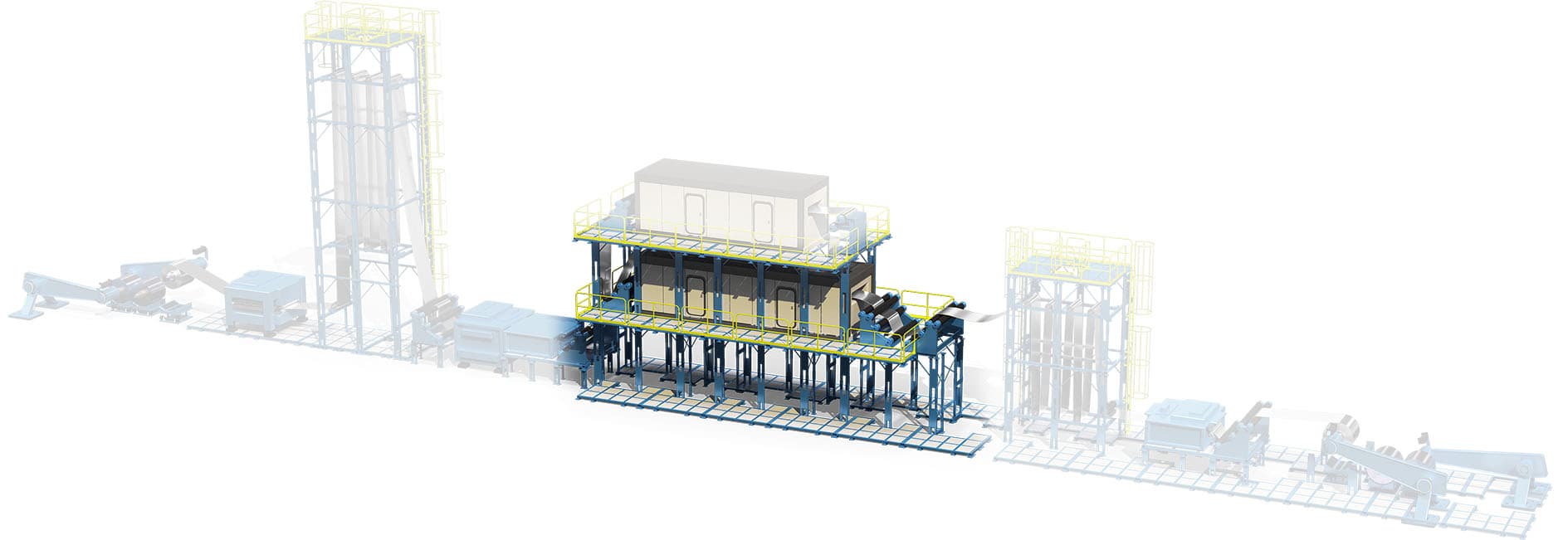

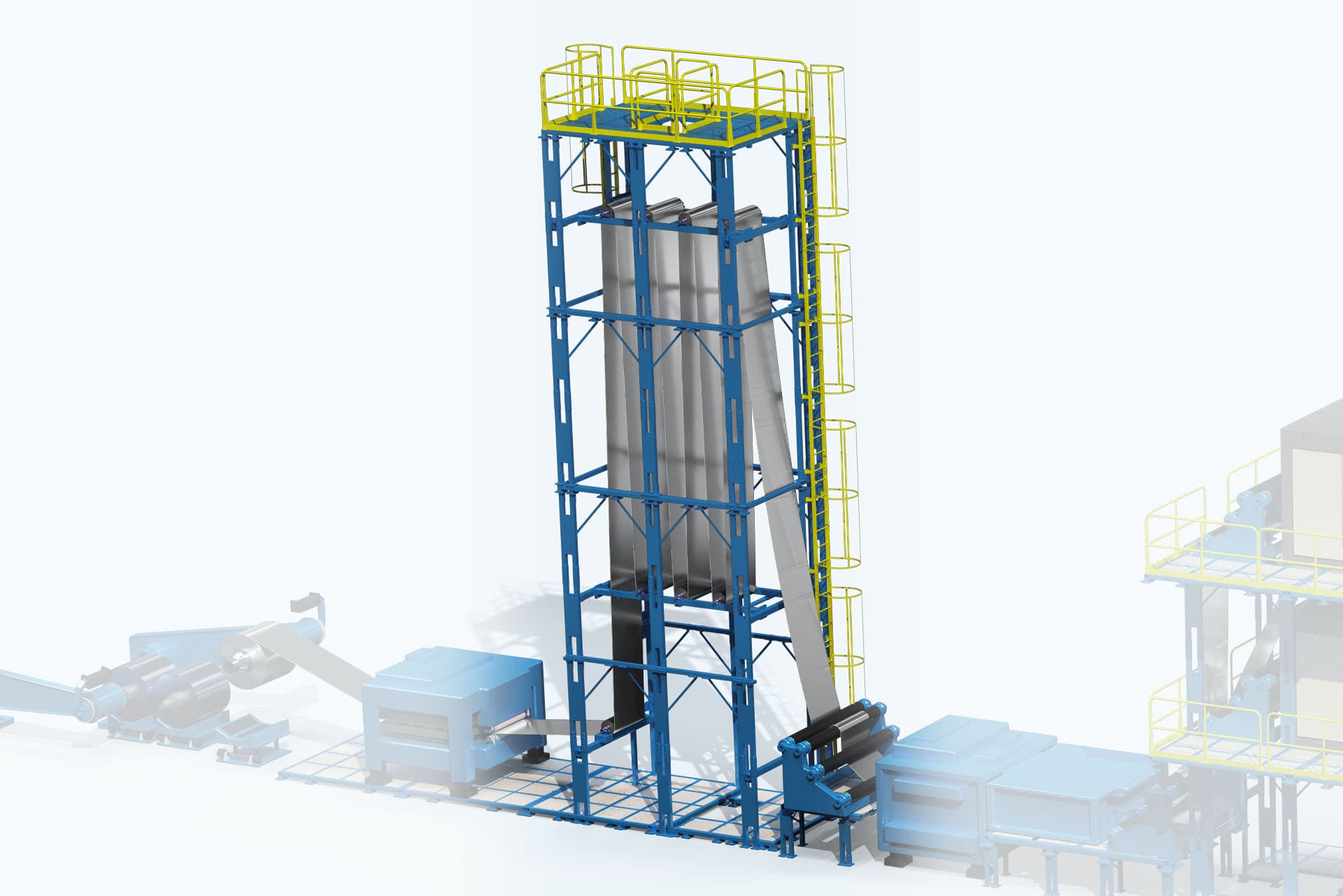

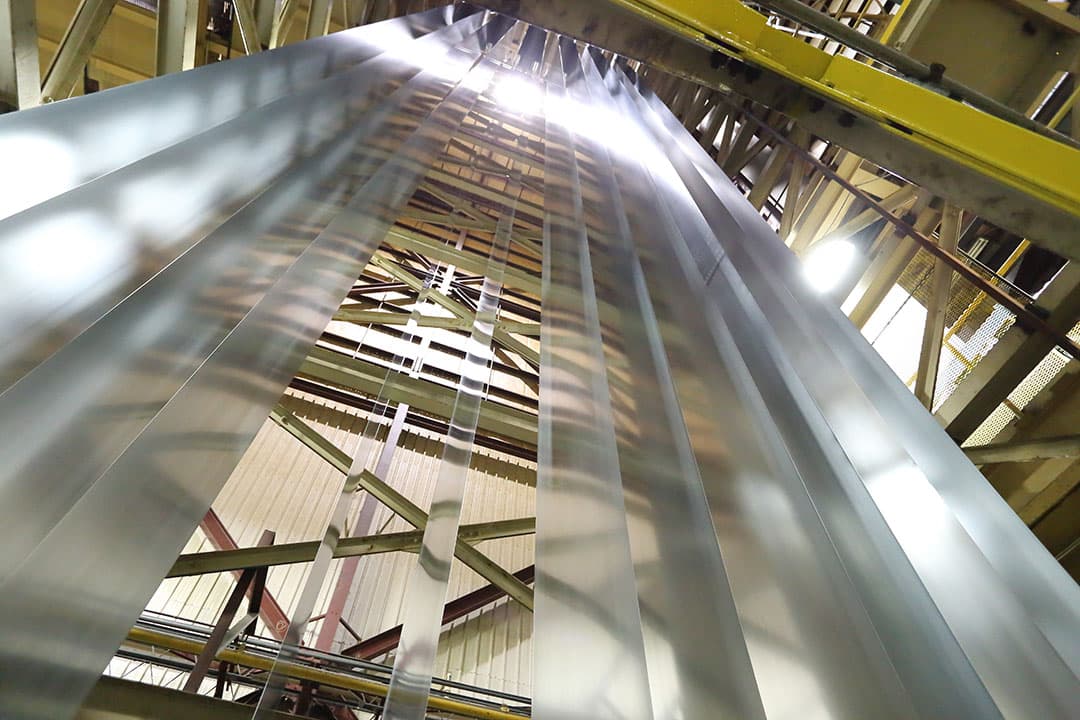

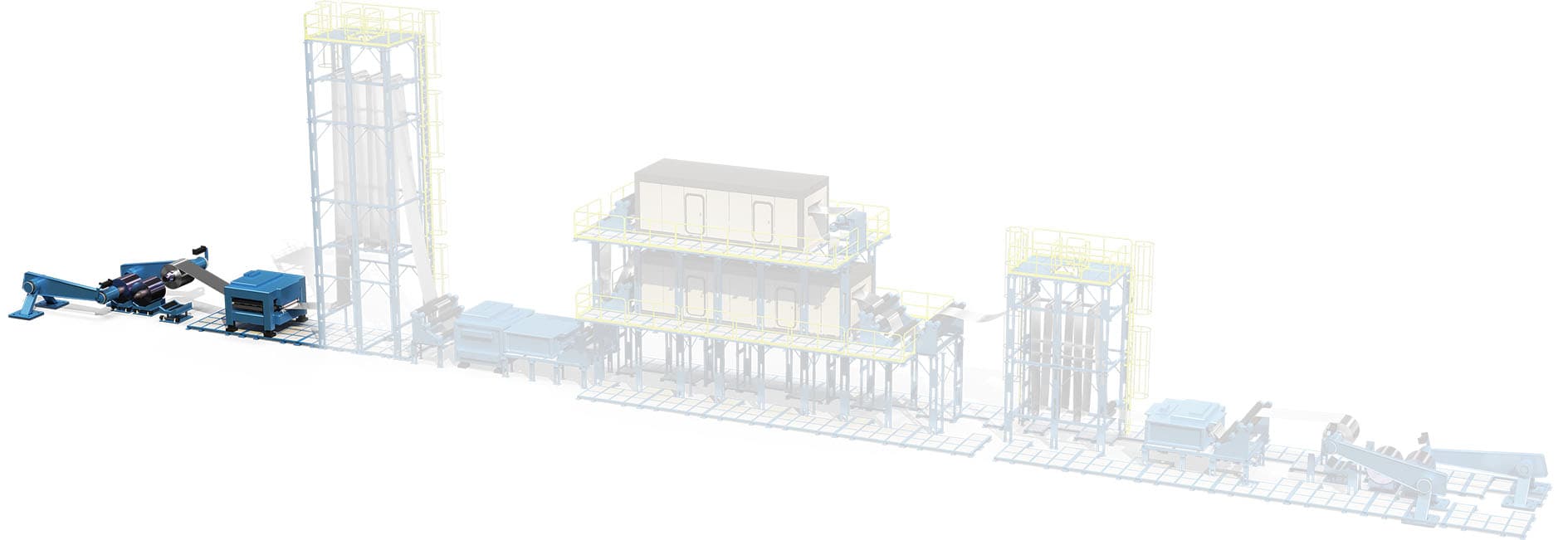

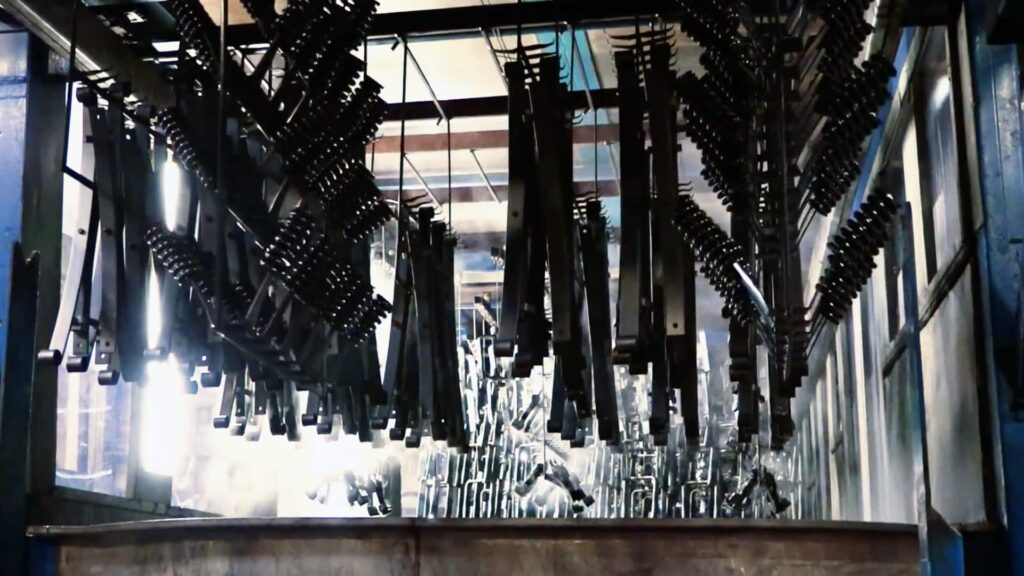

For nearly six decades, AZZ has been protecting critical infrastructure from the destruction of metallic corrosion as North America’s leading provider of galvanizing for fabricated steel. In addition to hot-dip galvanizing, AZZ offers a wide range of high-quality metal finishing and coating services. Our comprehensive metal coating capabilities create enduring infrastructure for constructing a stronger, safer, and sustainable world.

Explore Metal Coatings

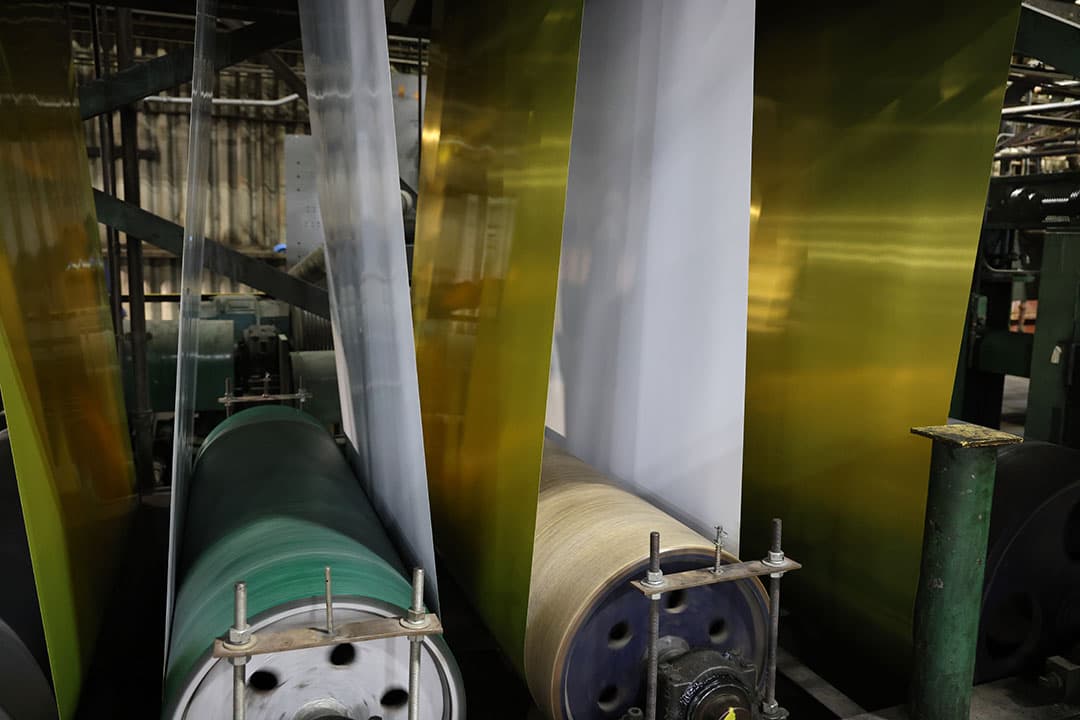

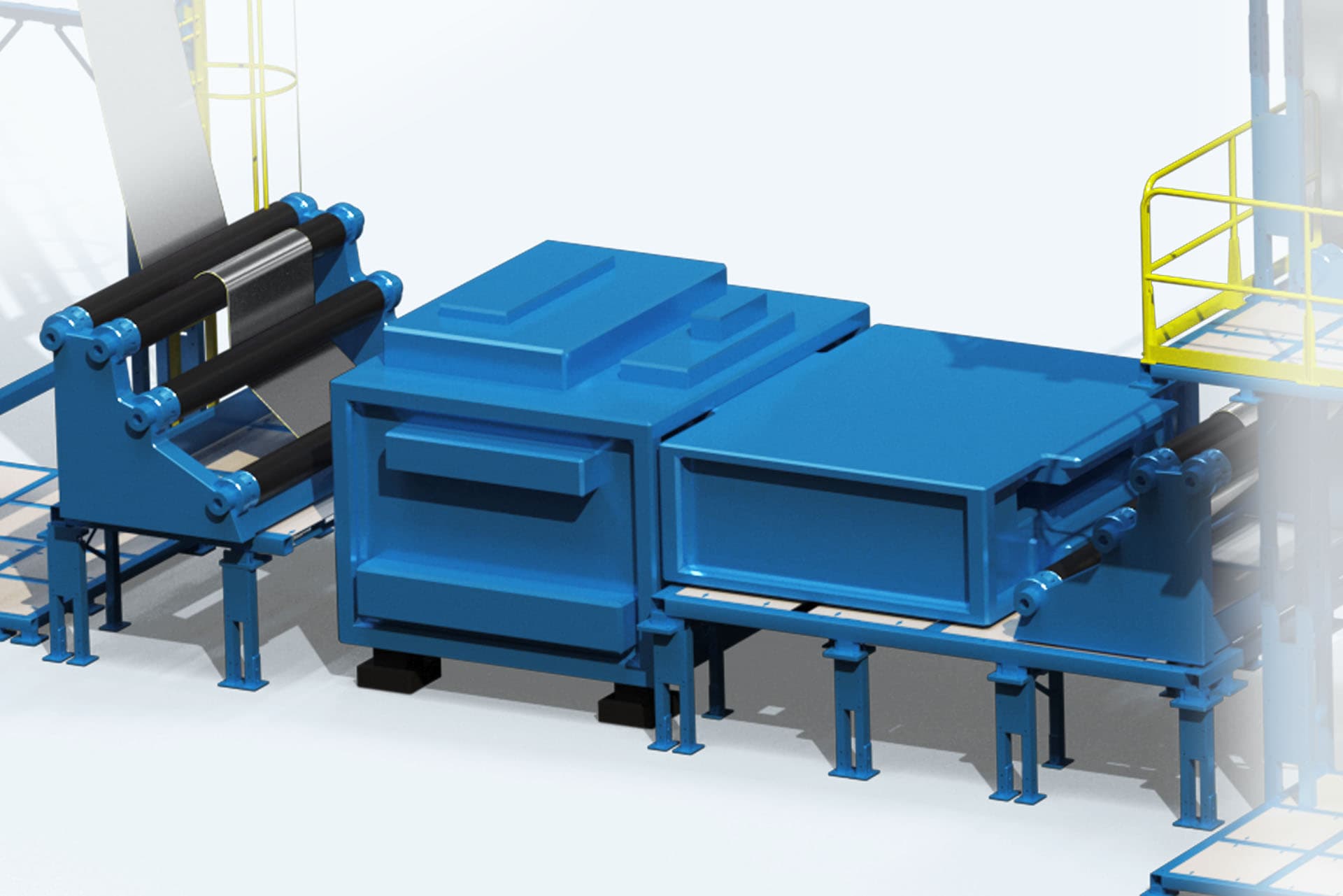

Surface Technologies

Surface Technologies

A collaborative partner for all your metal finishing and coating needs

Metal Coatings Locations