Dredge Boat

It is a dirty job, but somebody has got to do it. A tough, hardy little powerhouse, the dredge works up and down the Mississippi River on the east bank to provide access to the cruise terminals.

Galvanized: 2010

As many as 5,000 people per cruise are likely to see the dredge hard at work adjacent the River Walk of New Orleans.

In order for freight containers and cruise lines to have access to the Port of New Orleans, the Port Authority must maintain reliable depths at each of the wharves. The Mississippi leaves a natural accumulating deposit of sand and silt on the east side of the river that, if not removed on a regular basis, would make that side of the river inoperable. The Port had previously been contracting the dredge work but discovered the costs had become insurmountable.

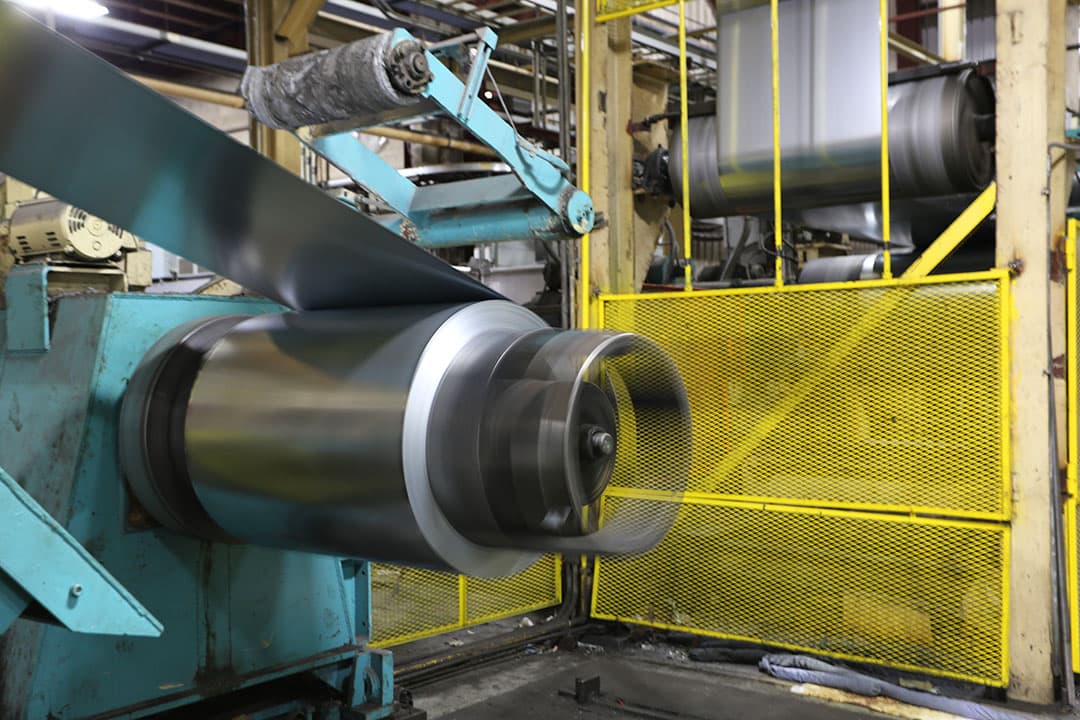

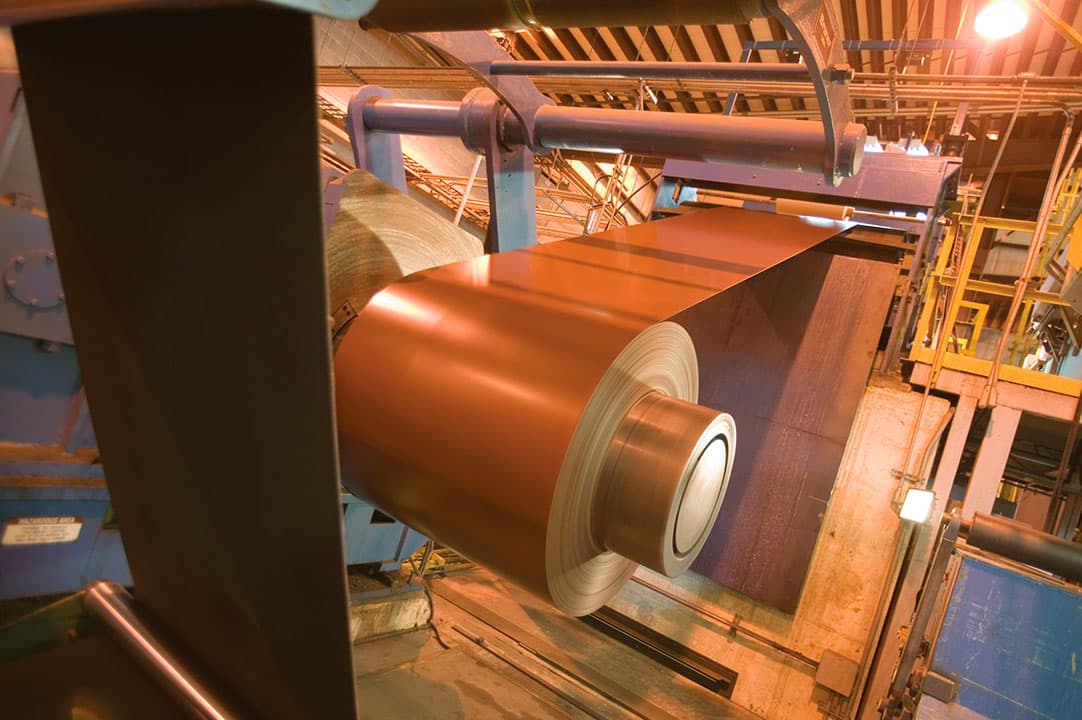

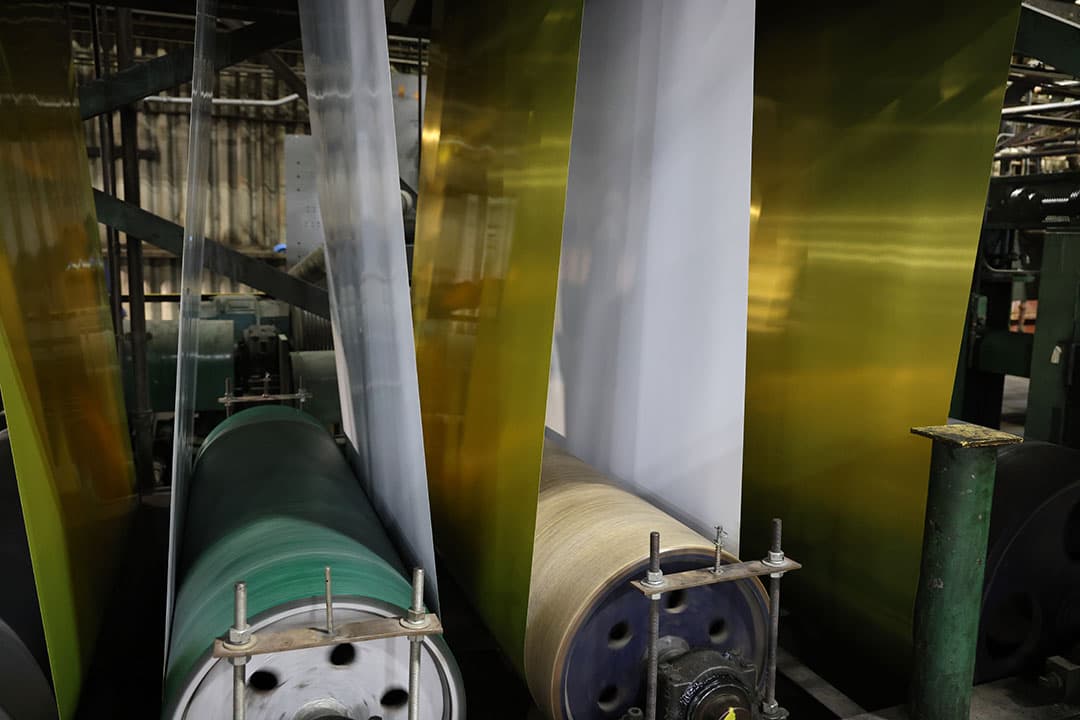

The Mississippi River, dubbed “the Big Muddy,” has a high salt content at the mouth of the river and is full of rough sand. That paired with the abrasion of rapidly moving water make an extremely harsh and corrosive environment. Hot-dip galvanized (HDG) steel is the only corrosion protection system strong enough to withstand the abuses of life on the Big Muddy. With zinc-iron alloy layers of up to 250 diamond pyramid number (DPN) hardness protecting the steel beneath, the durable zinc coating is more difficult to penetrate than the substrate steel it protects. Such strength is required on a watercraft that will continually be exposed to rough handling, moisture and chemicals in its day-to-day operations.

New to galvanizing, the manufacturer worked closely with AZZ to ensure all steel would galvanize successfully and on time. The dredge had to be ready for its christening, so communication and turnaround time of the galvanized elements were critical.

As hot-dip galvanizing is an indoor, factory controlled process, AZZ was able to provide a customized turnaround to meet production schedules. All stairs, ladders, walkways, work platforms and handrails of the dredge were galvanized, totaling 10 tons. Upon completion of the project, the manufacturer was so impressed with the quality of galvanized steel he rewrote their specifications to include HDG.

Use of galvanized steel on the dredge is impacting the entire workboat market operating on America’s rivers and waterways. Owner-operators and government agencies are searching for durable, cost-effective methods of corrosion prevention in this harsh and abrasive environment. Galvanized steel is the ideal solution.

Contact Us

Email Signup

Sign up to receive the latest news from AZZ