Towmaster

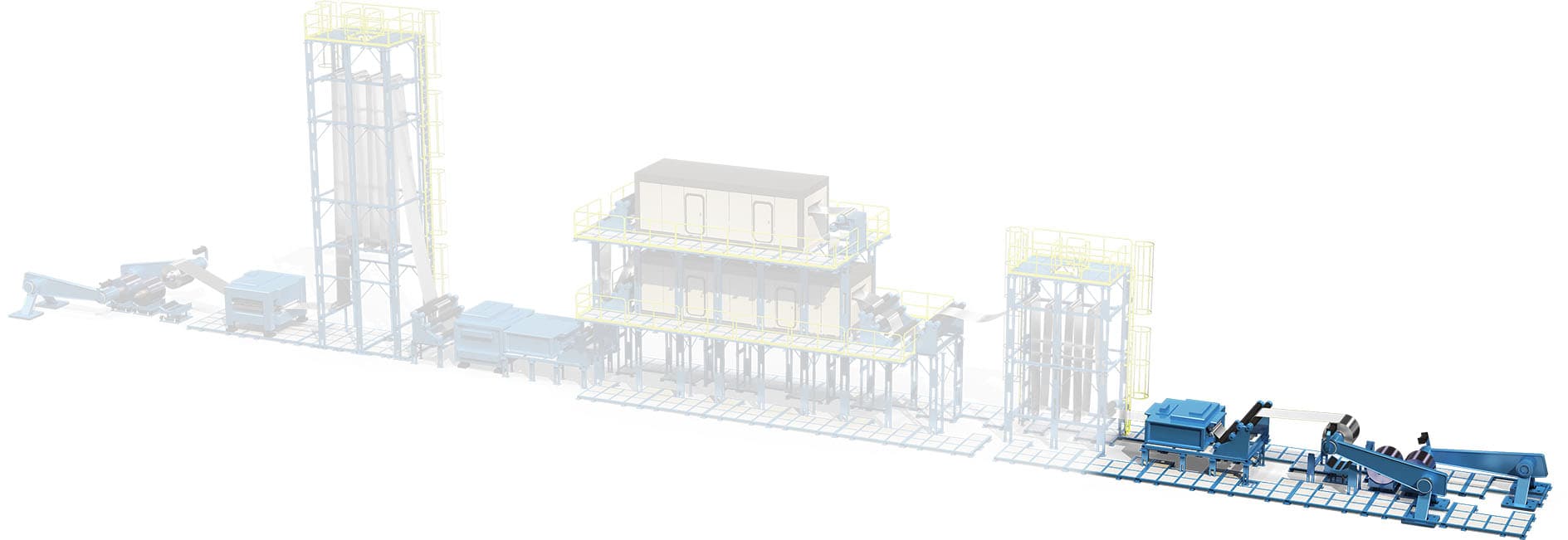

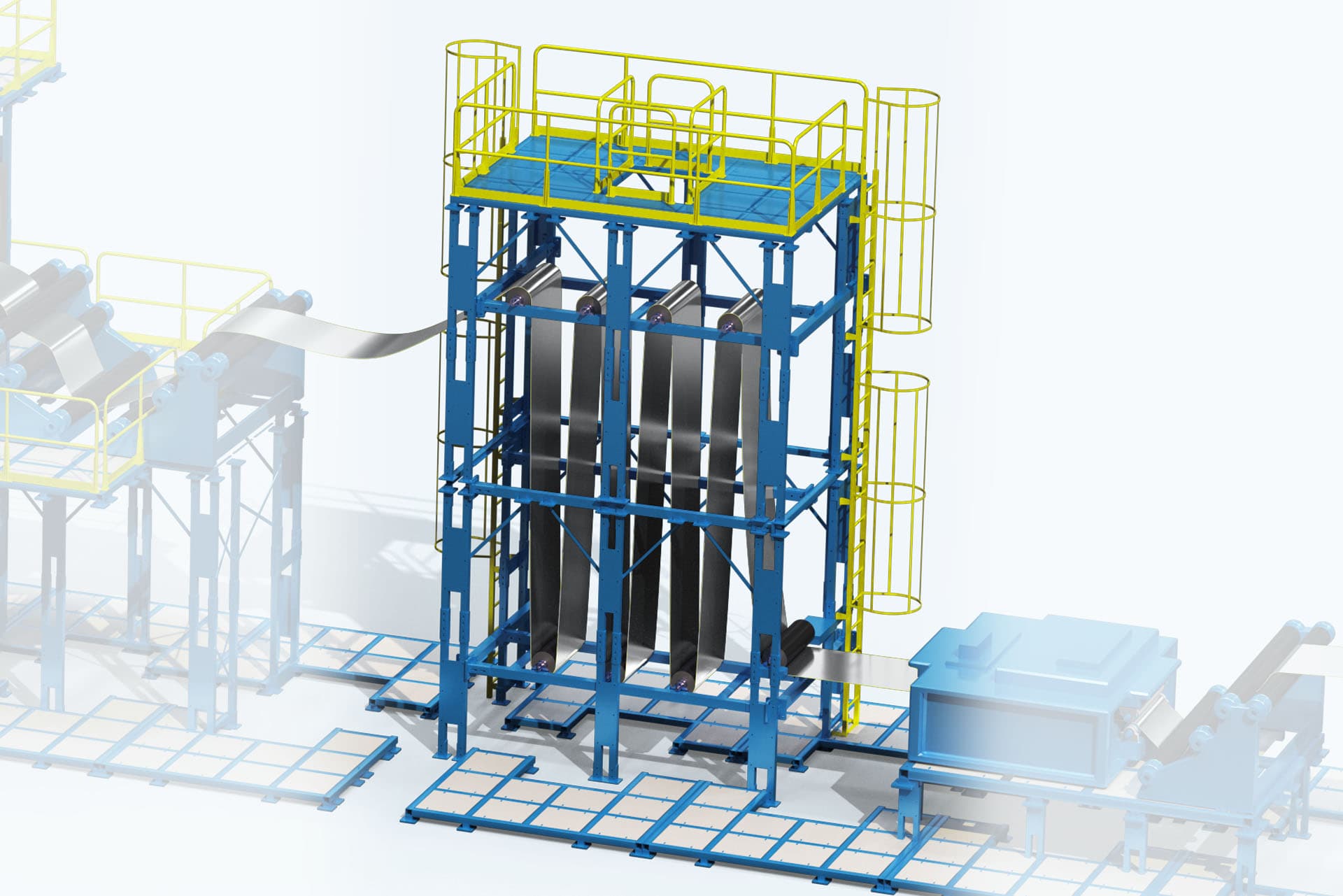

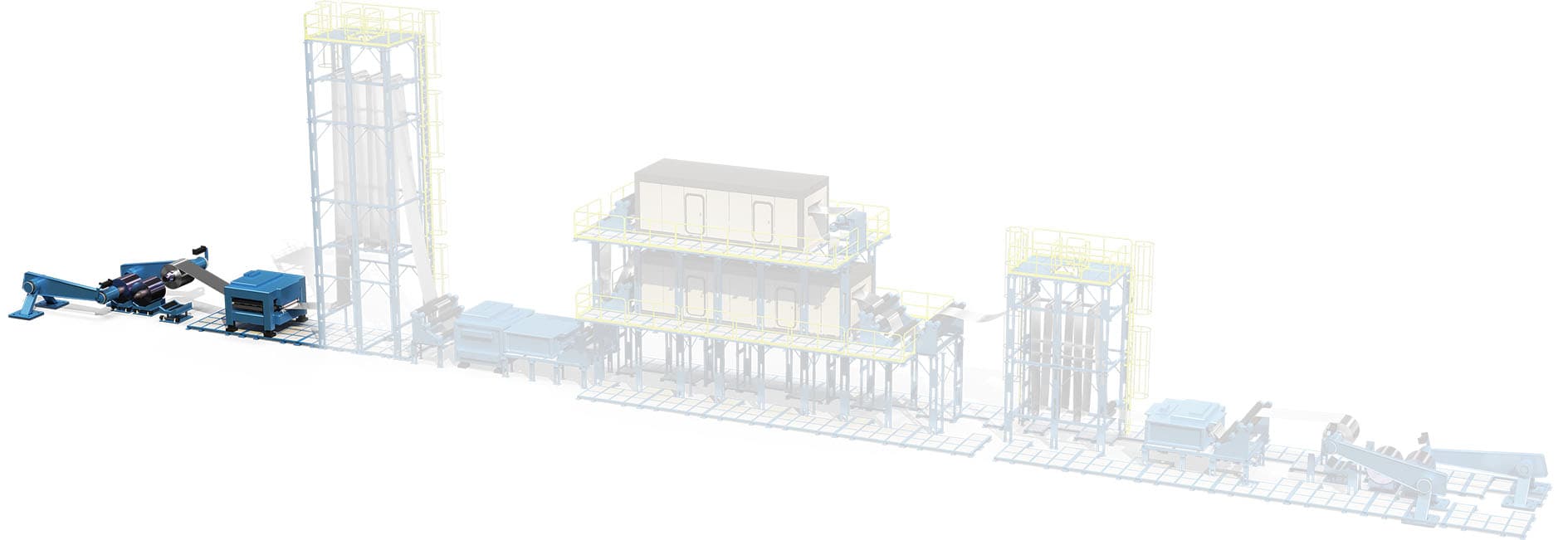

The trailer manufacturer prides itself on building tough trailers built for tough duty. In 2010, they made the decision to start hot-dip galvanizing their trailers to provide a competitive advantage.

Leading the way in reliability, sustainability and cost-effectiveness

Date galvanized: 2010

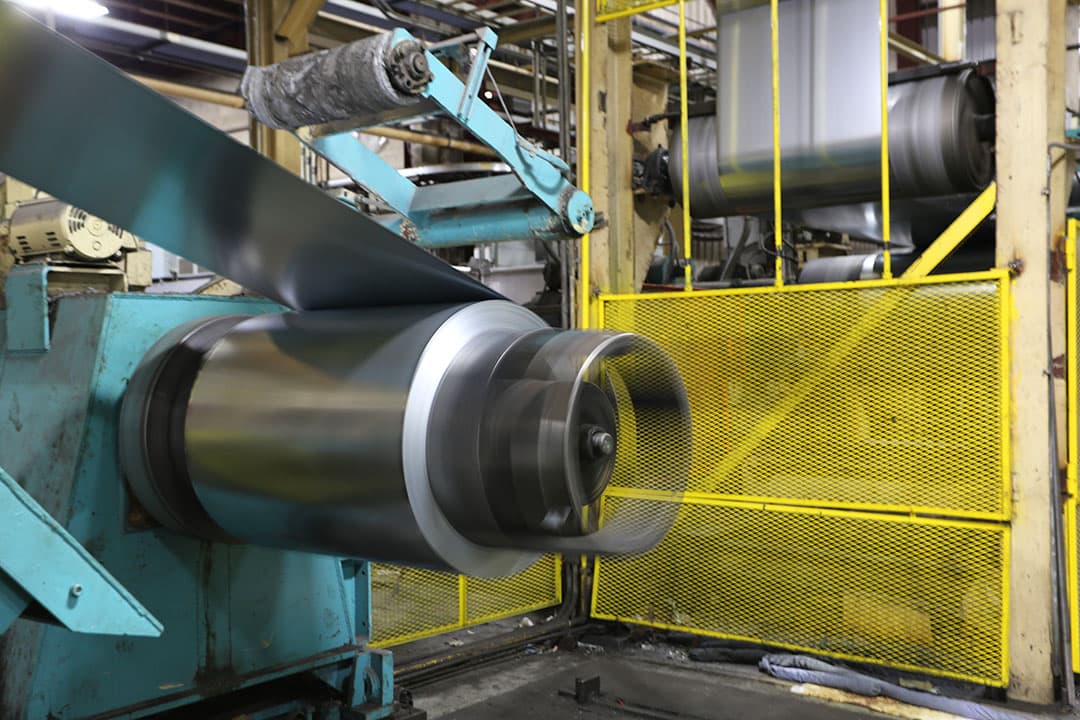

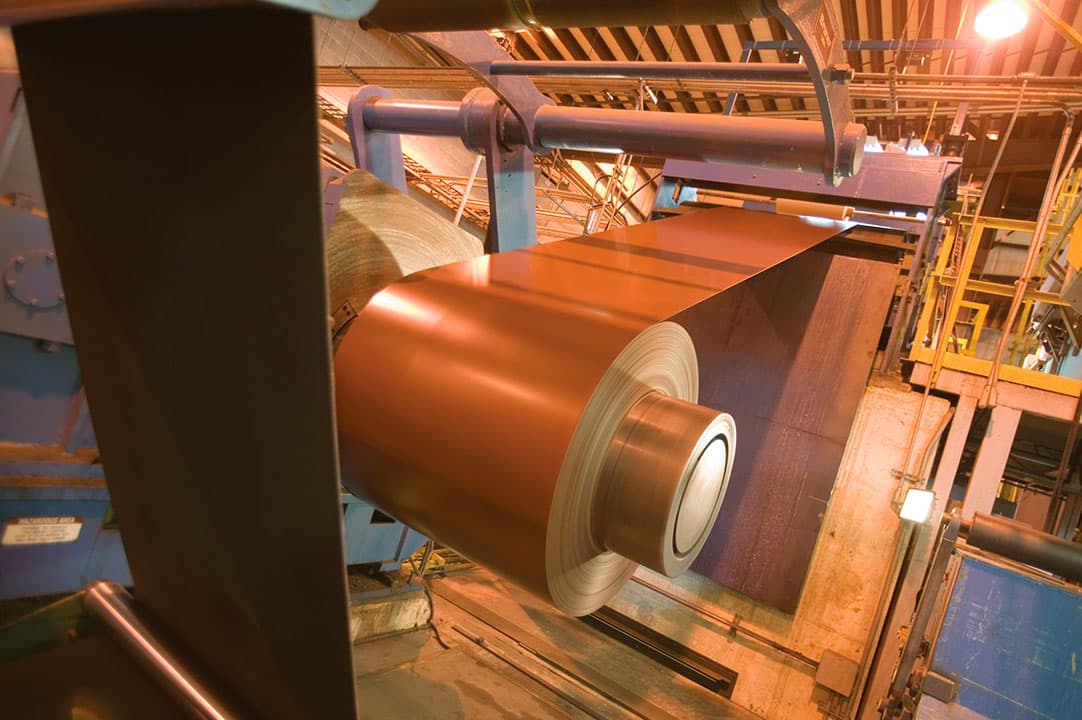

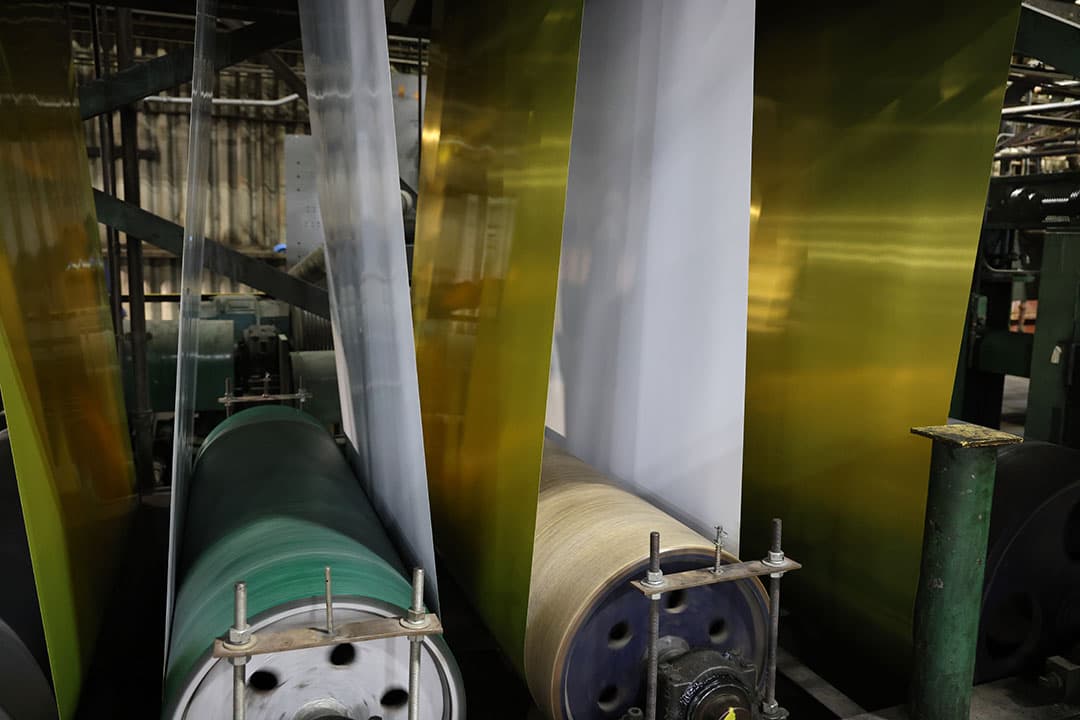

Originally, the manufacturer was a little concerned about galvanizing’s finish, as they were competing with painted trailers. However, they knew hot-dip galvanizing would provide a longer life for their trailers – keeping them looking great longer than painted counterparts and ultimately saving money.

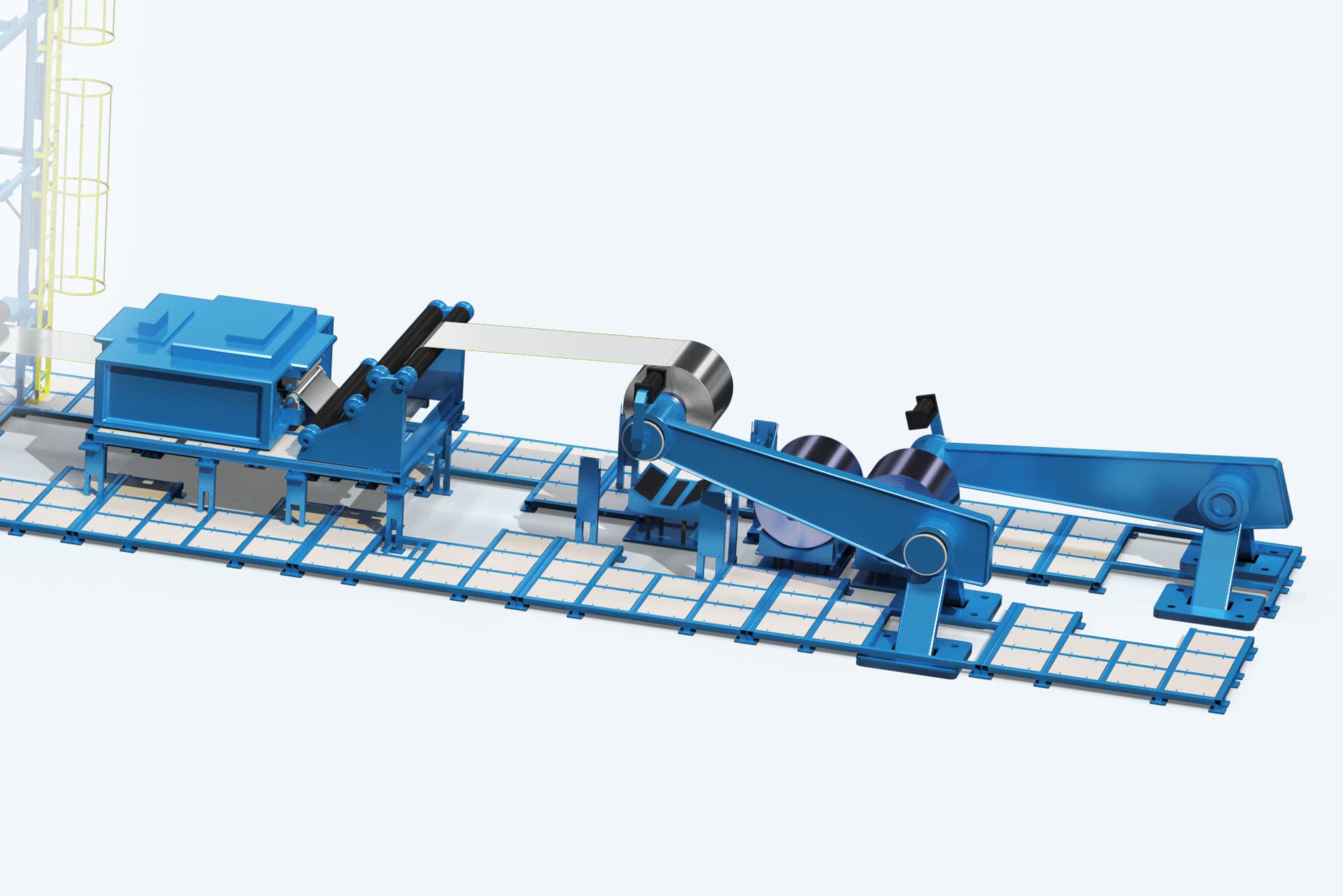

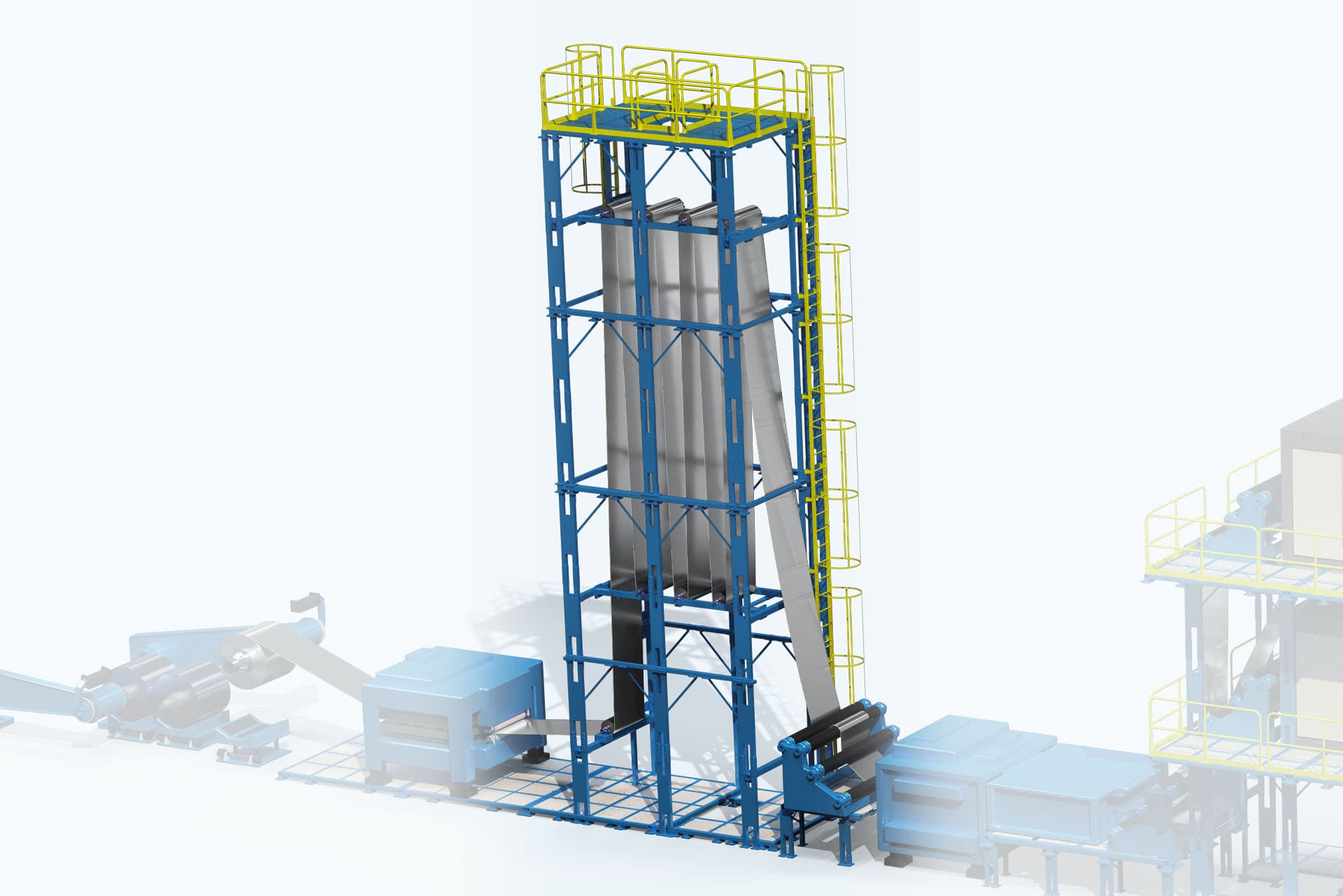

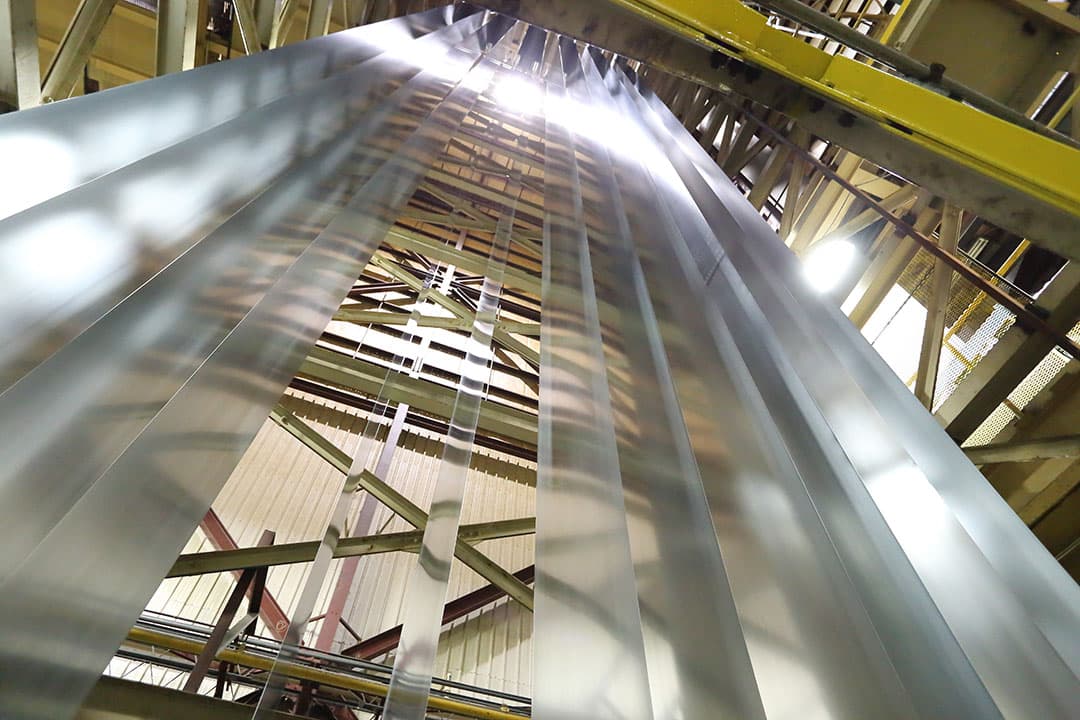

The manufacturer collaborated with AZZ during the design of the trailer to be sure every square inch of exposed surface would be coated. Working together, the design engineers were able to ensure 98 percent of every trailer is galvanized. Galvanizing the trailers provides a long maintenance-free life, even after continual exposure to road salts.

The manufacturer not only enjoyed economic savings afforded by galvanizing, but also conserved natural resources as the trailers were utilized two to three times longer than the painted trailers. Thanks to their forward thinking and specification of hot-dip galvanizing, their trailers will lead the way in reliability, sustainability and cost effectiveness for generations.

Contact Us

Email Signup

Sign up to receive the latest news from AZZ