For months on end, parents, grandparents, aunts, uncles, and an assorted mix of friends and family, drive to baseball games in cars loaded down with collapsible lawn chairs, portable coolers, and sports bags. In many areas, you would be hard pressed to find a room full of people where not a single one had at least a few memories of picking at the grass in leftfield, or going to a game to cheer on a young player.

When the Clifton Forge Little League in Allegheny County, Virginia needed two baseball fields to mentor children and host tournaments, the organization was fortunate to connect with the innovative and talented design/buildLAB at Virginia Tech’s School of Architecture. Students who participate in this project-based experiential learning program conduct research and help implement cutting-edge construction methods and architectural designs. The design/buildLAB collaborates with industry experts to create charitable projects that will enrich local communities.

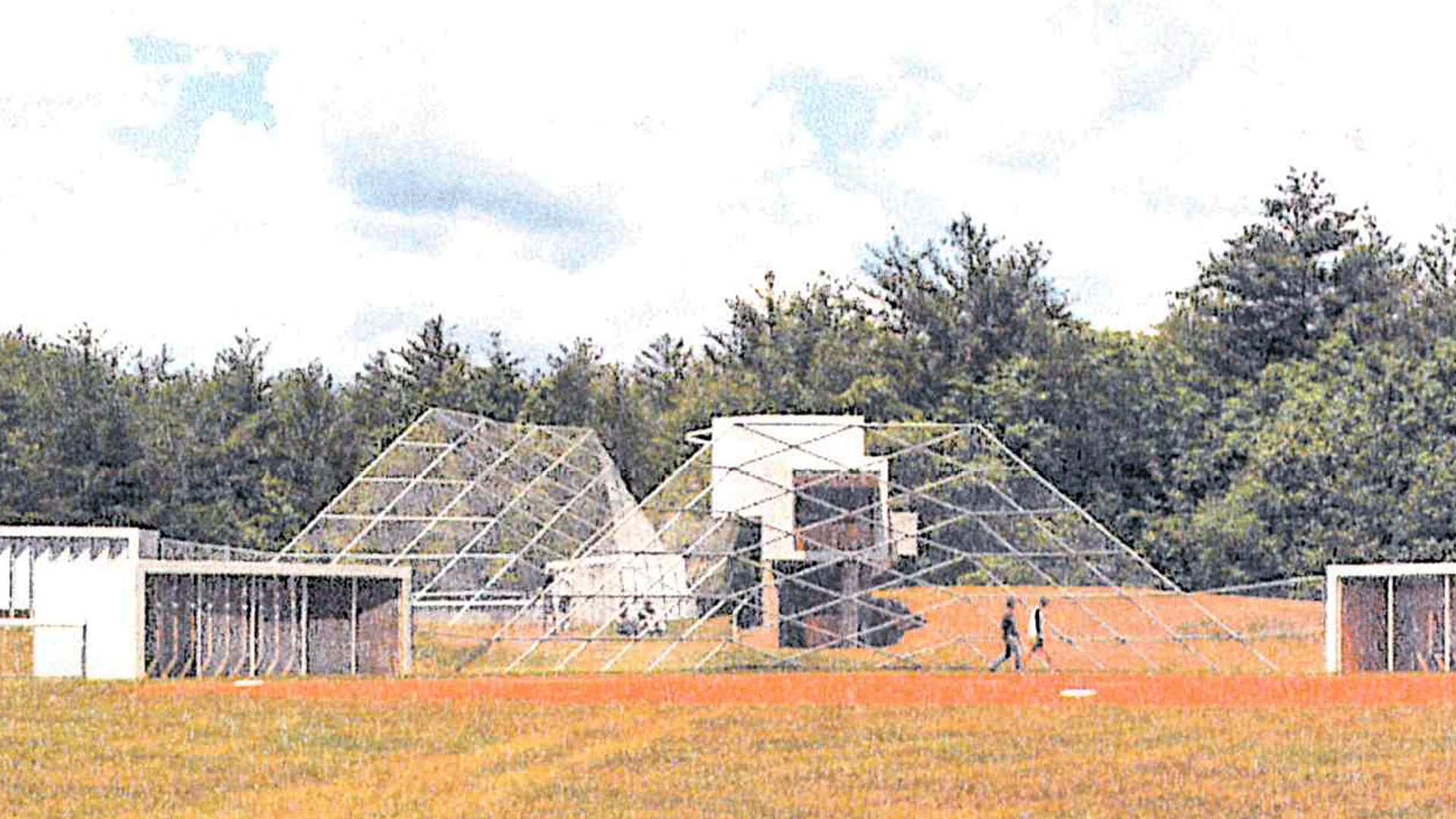

As a result of the dedicated efforts and vision of the design/buildLAb team, Sharon Fields transformed from a dream into a reality for the children of Allegheny County. The two fields and press box feature two 45’ by 25’ backstops fabricated out of a light gauge steel tubing, which was progressively dipped and reassembled in the field. This material allowed for easy handling and assembling for the team. AZZ Galvanizing – Bristol was pleased to help with the construction and was recently recognized for its work on the project by the American Galvanizers Association for Excellence in Hot Dip Galvanizing: Civic Contribution.

A key factor in the design of Sharon Fields, which recently won the 2016 AIA Blue Ridge Design & Construction award, is the durable, maintenance-free materials chosen by the Virginia Tech team. The architectural students knew the Clifton Forge Little League Team operates as a non-profit with a tight budget and needed the new facility to offer longevity and low maintenance costs. The hot-dip galvanized steel they chose for the project will ensure that several generations of Little Leaguers will be able to enjoy the new fields. This zinc-coated material is long lasting – offering corrosion protection in a variety of climates as well as a natural, clean, rust-free look. For this project in particular, the material was a wise choice because the student architects knew the backstops would be exposed to rain, sunlight and cold temperatures yet still have to protect spectators season after season.

AZZ Galvanizing – Bristol is proud to have helped in the construction of this useful community facility, and looks forward to seeing Allegheny Country families enjoy it for years to come.

To learn more about AZZ and its processes, visit AZZ.com today!