Plating

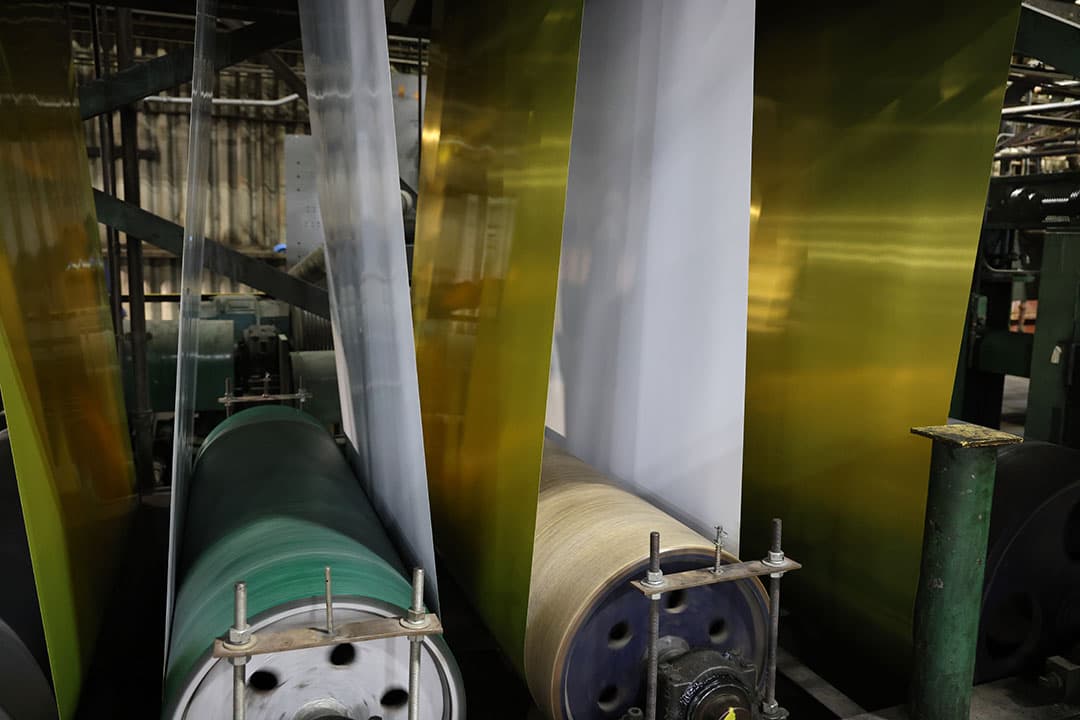

Anodizing, chemical film, and zinc plating for aluminum and steel components and substrates

Durable protection, high-spec capabilities, and operational agility

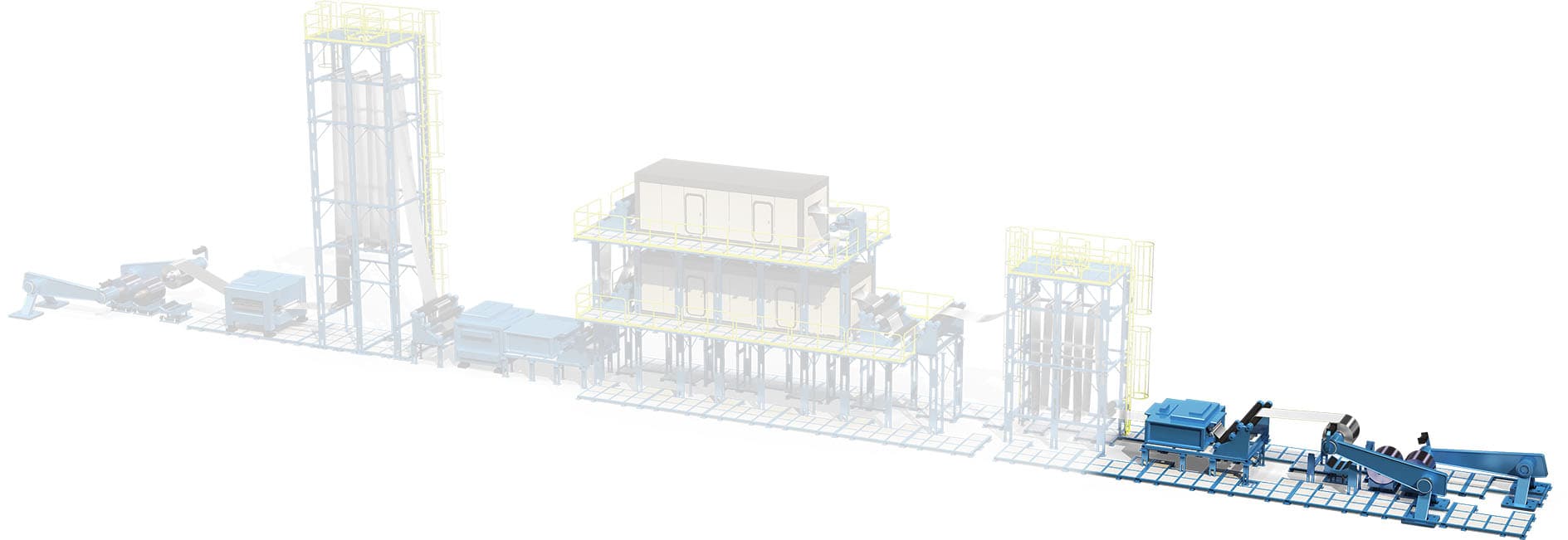

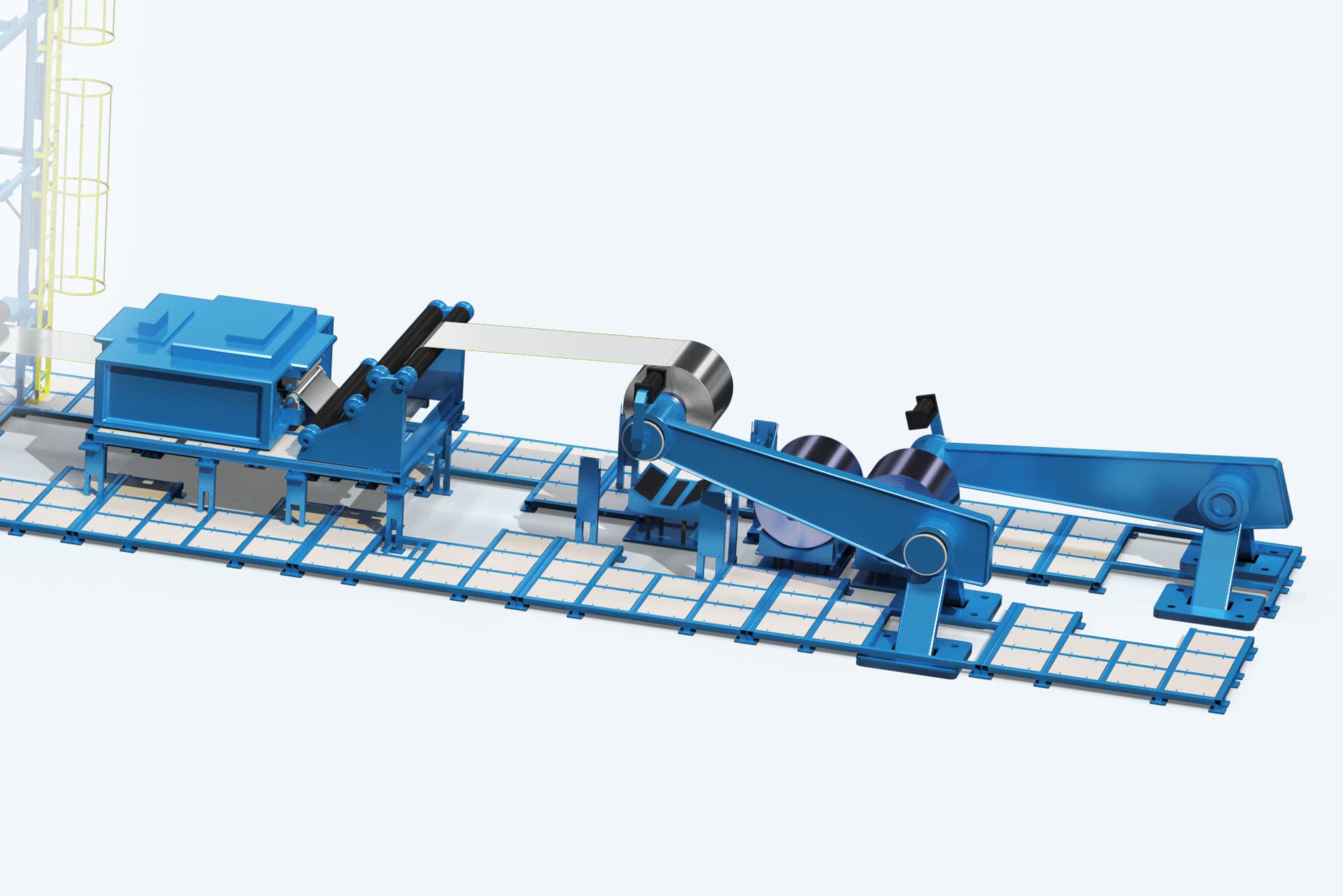

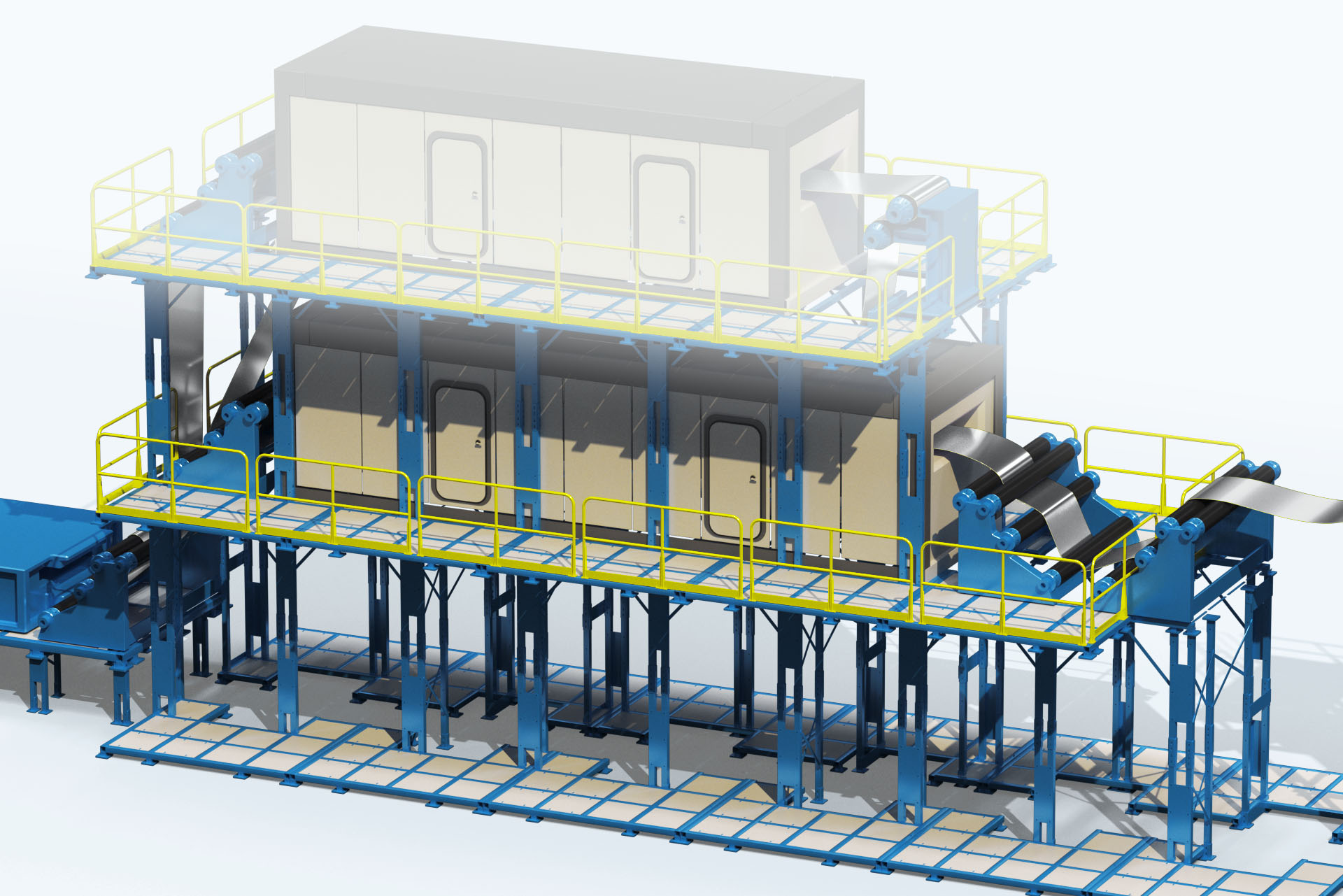

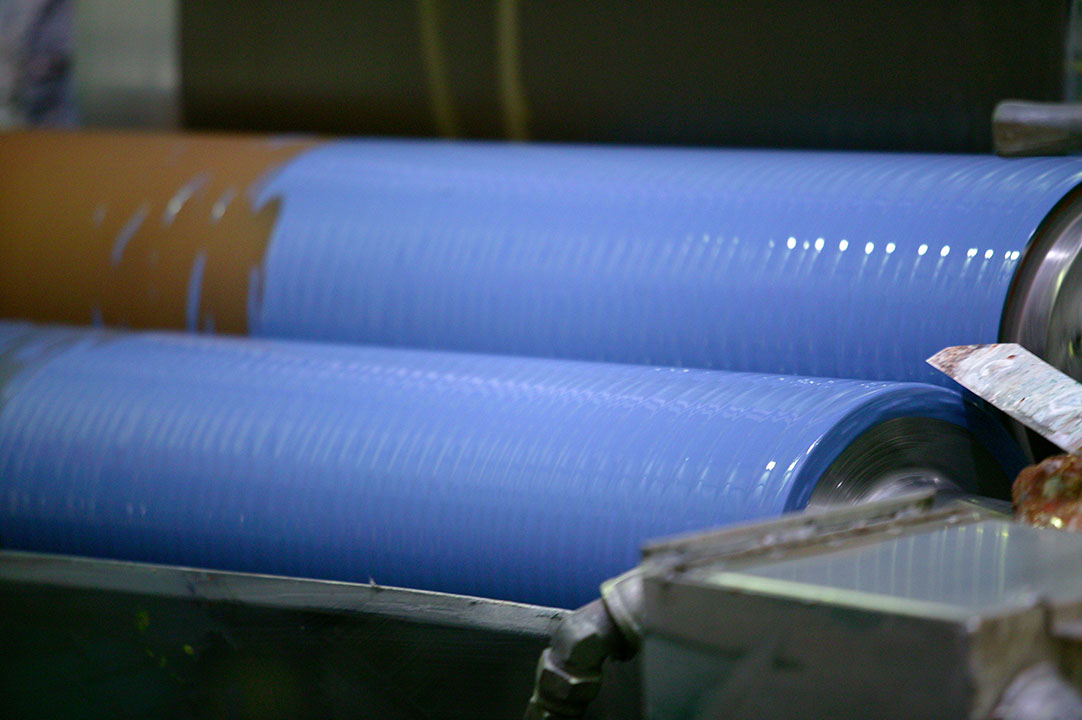

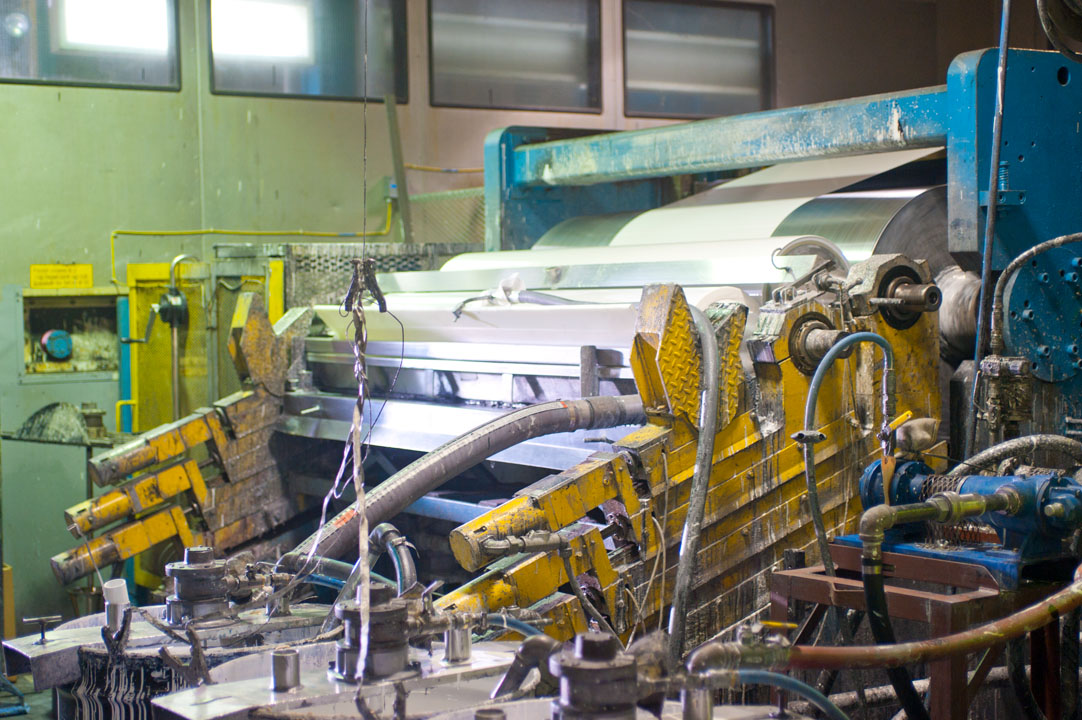

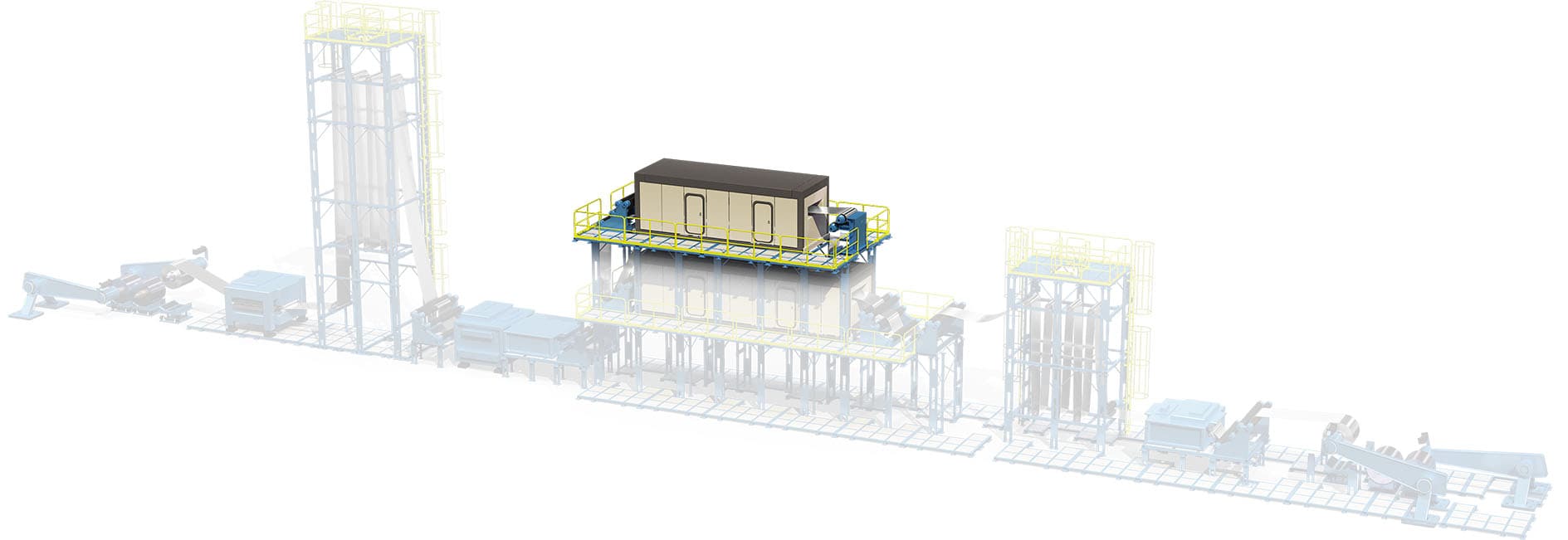

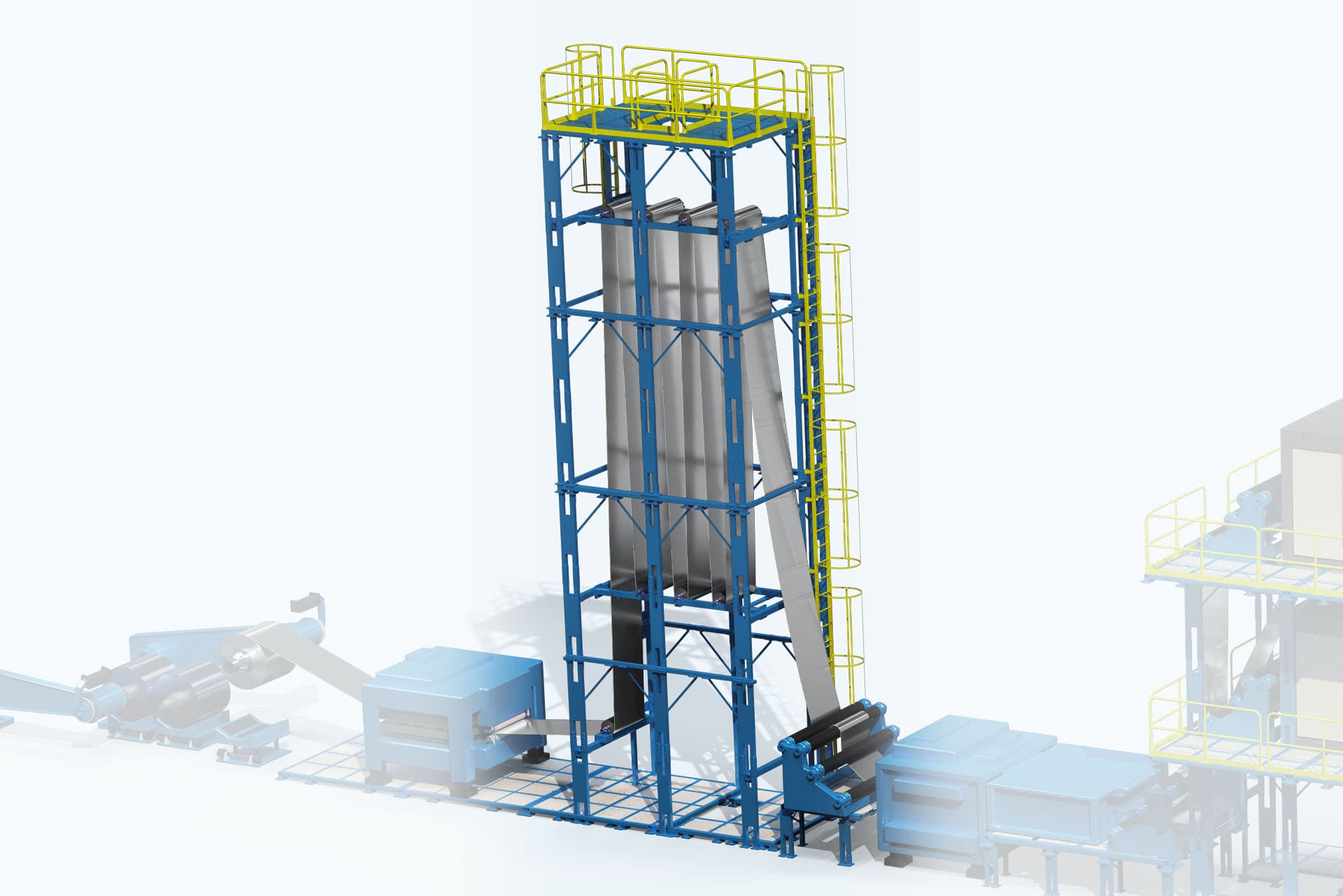

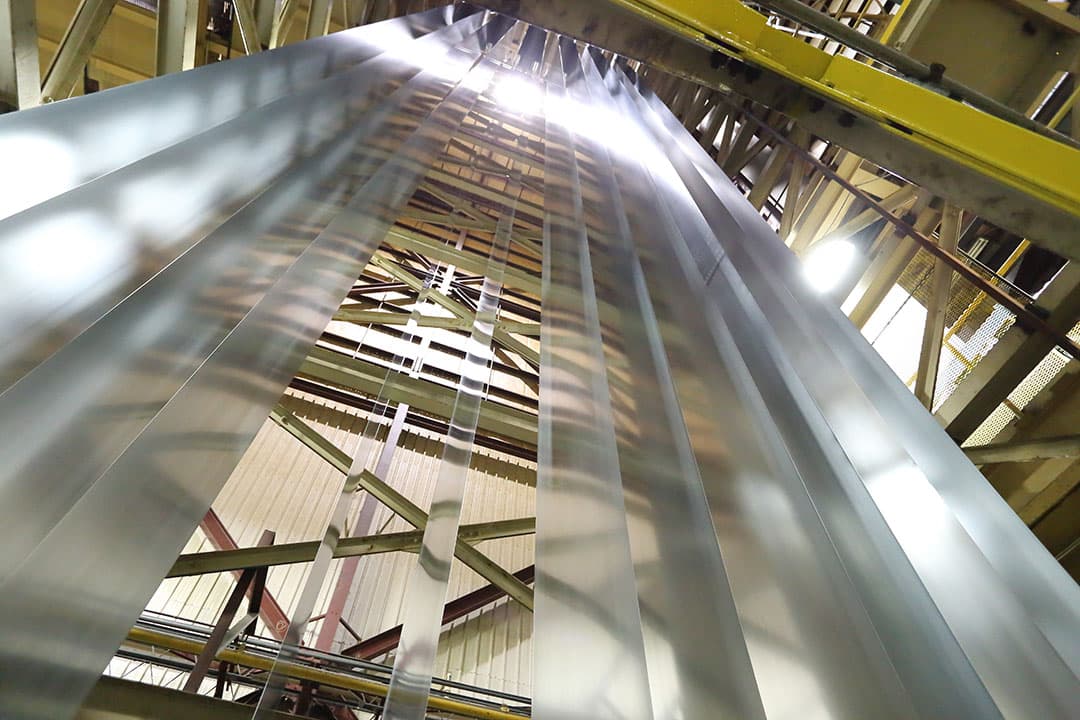

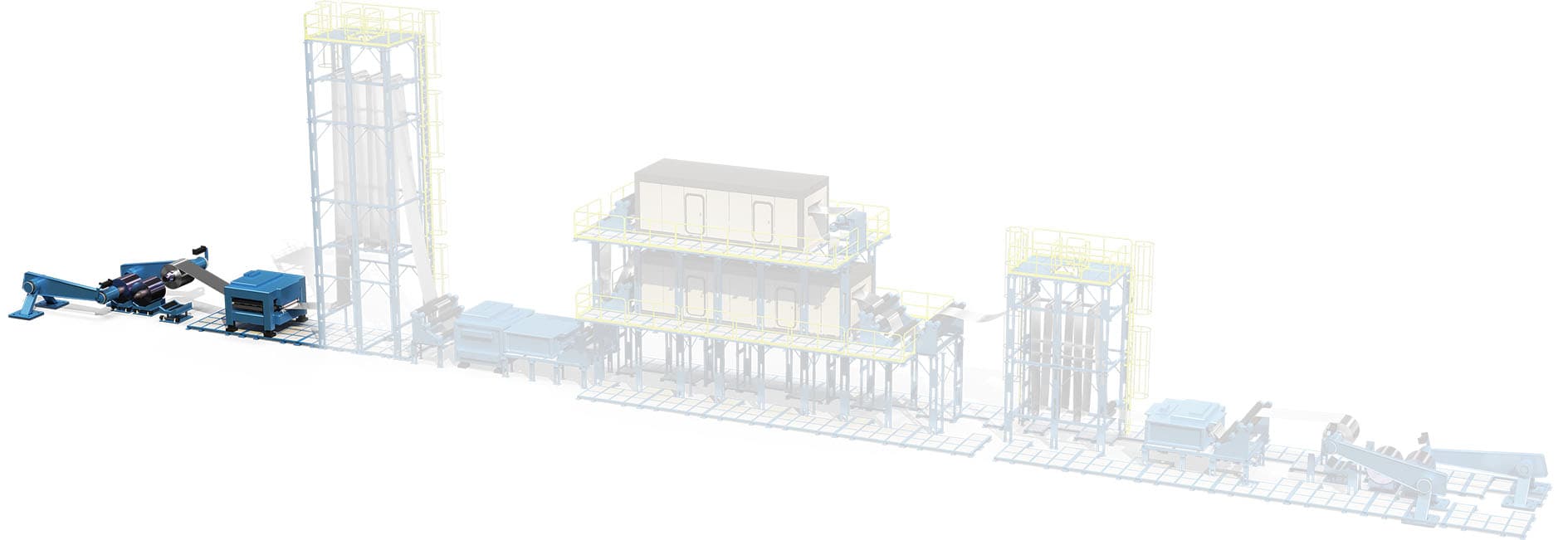

AZZ’s highly automated plating operations have high-volume production capacity and provide fast turnaround times, enabling us to integrate seamlessly into your supply chain. Our state-of-the-art technologies provide durable corrosion protection for substrates and components of varying sizes, as well as high-spec, intricate designs.

AZZ Plating Processes

- Anodizing

- Zinc Plating

- Nickel Plating

- Embrittlement

- Electroless Nickel (High and Mid Phos)

- Bright Nickel Plating

- Chromate Conversion Plating

AZZ Chemical Processes

- Anodizing (Type II)

- Chemical Film

- Passivation

- Zinc Phosphate

- Zinc Plating

More Surface Technologies

Duplex Coating

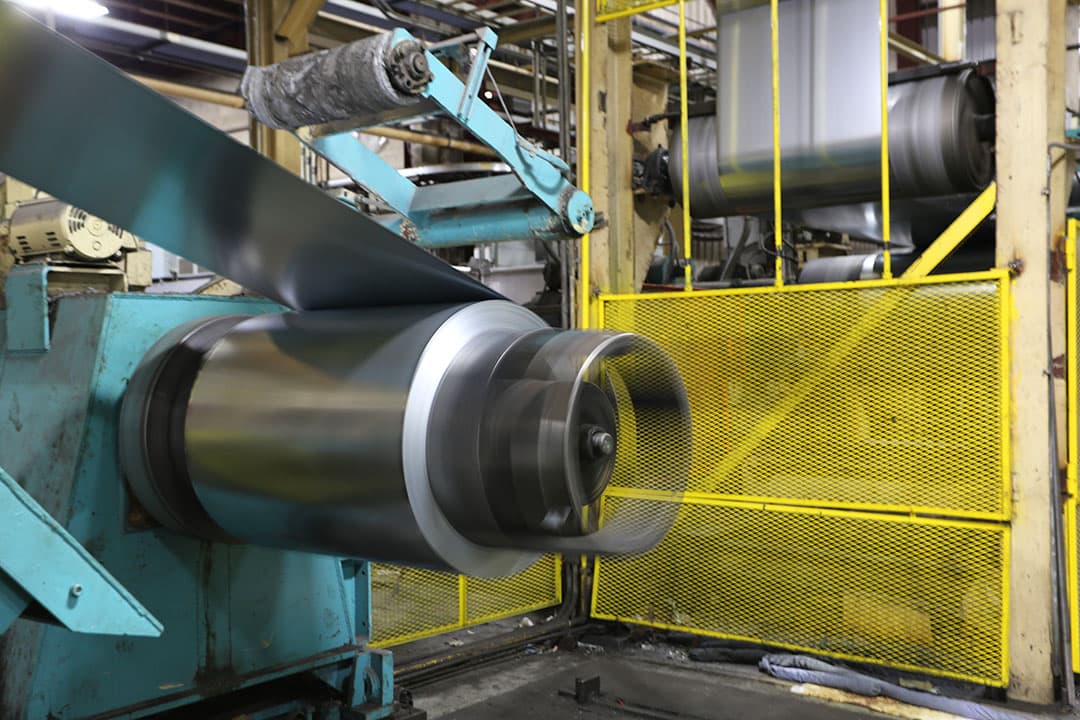

Duplex Coating

Optimal protection achieved through the synergies created by combining hot-dip galvanizing and powder or wet coating

Powder Coating

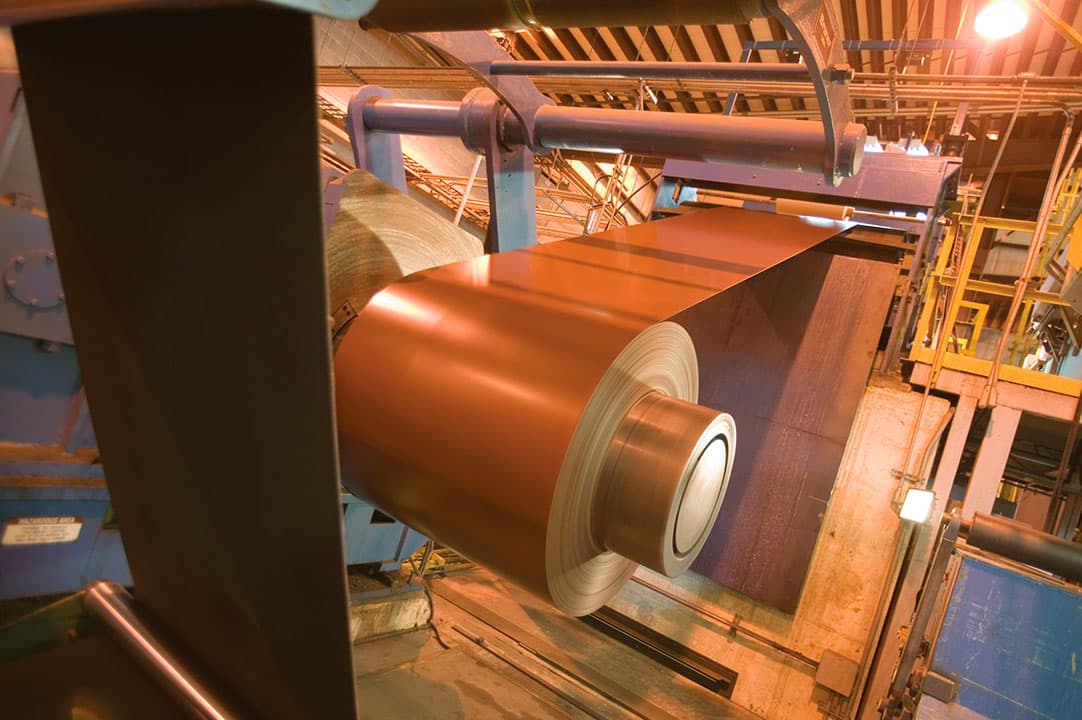

Powder Coating

Durable coatings which provide long-lasting corrosion protection in an array of colors and textures

Surface Prep

Surface Prep

Highly skilled experts provide sandblasting services, the surface preparation critical for a consistent, high-quality finish

Wet Coating

Wet Coating

Solvent-based paint formulations in an array of colors wet blasted for consistent coverage and corrosion protection