Powder Coating

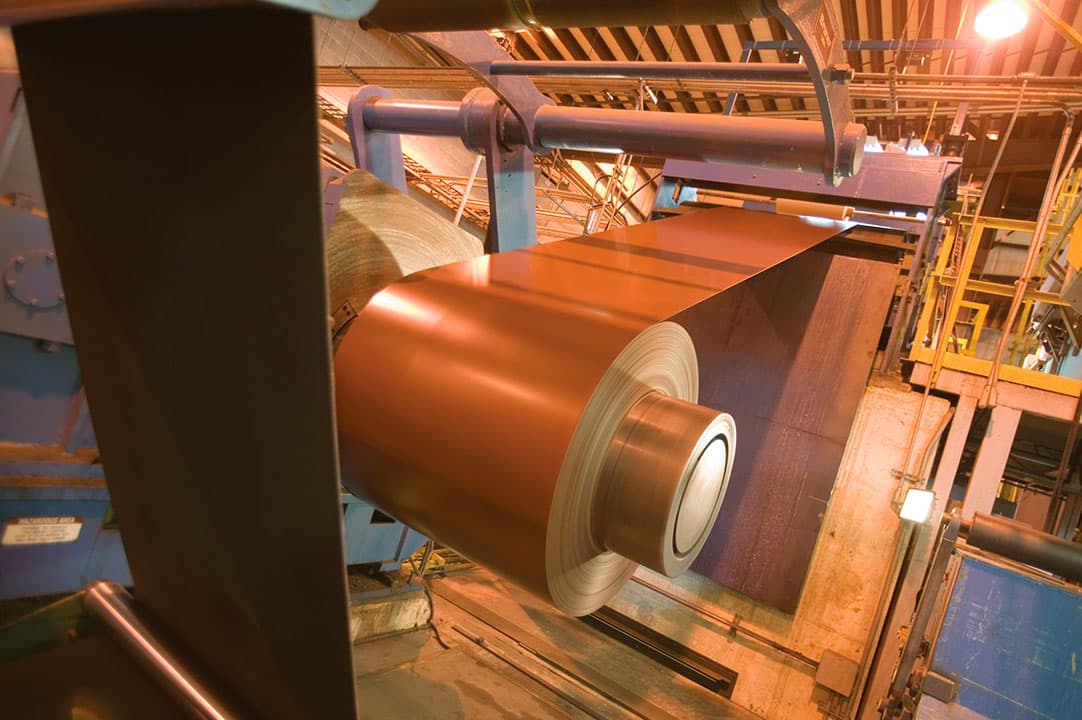

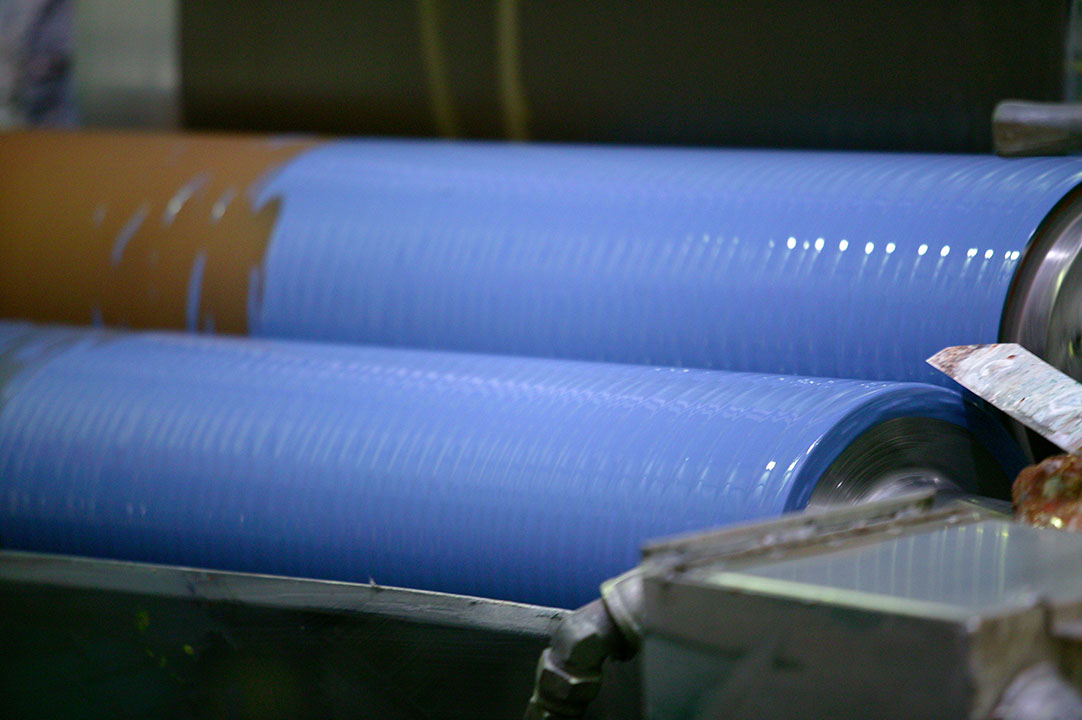

Durable coatings which provide long-lasting corrosion protection in an array of colors and textures

Our expansive network is equipped for high volume and fast turnaround

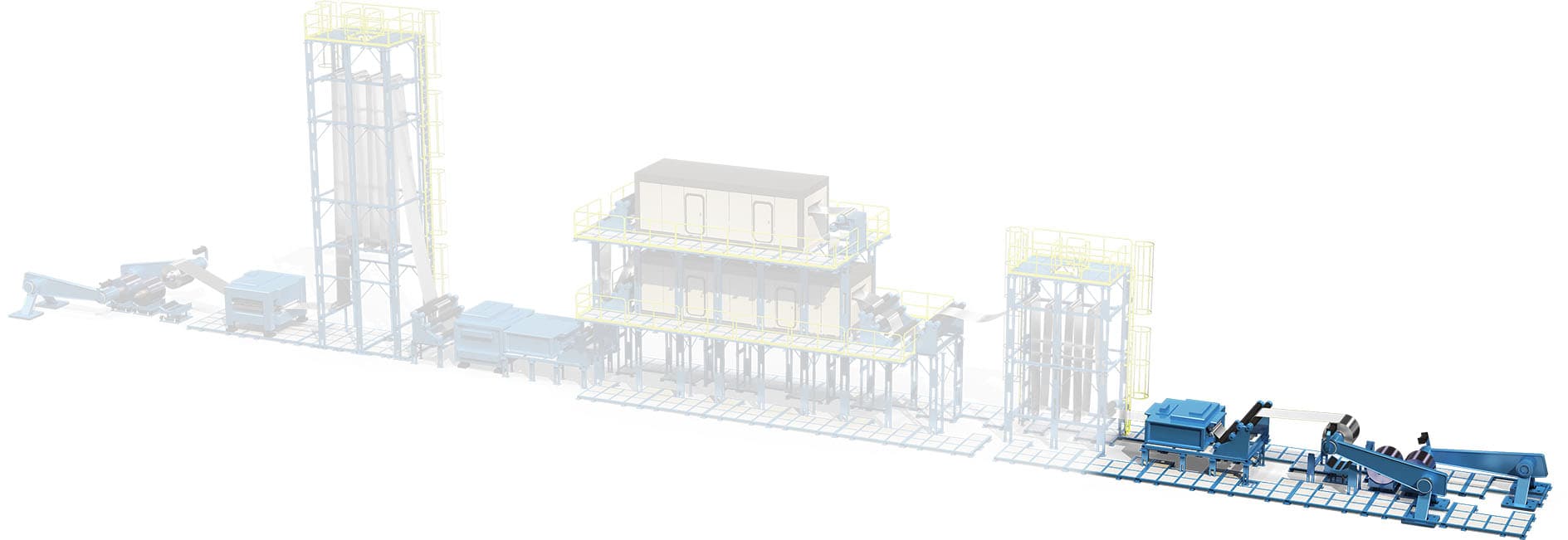

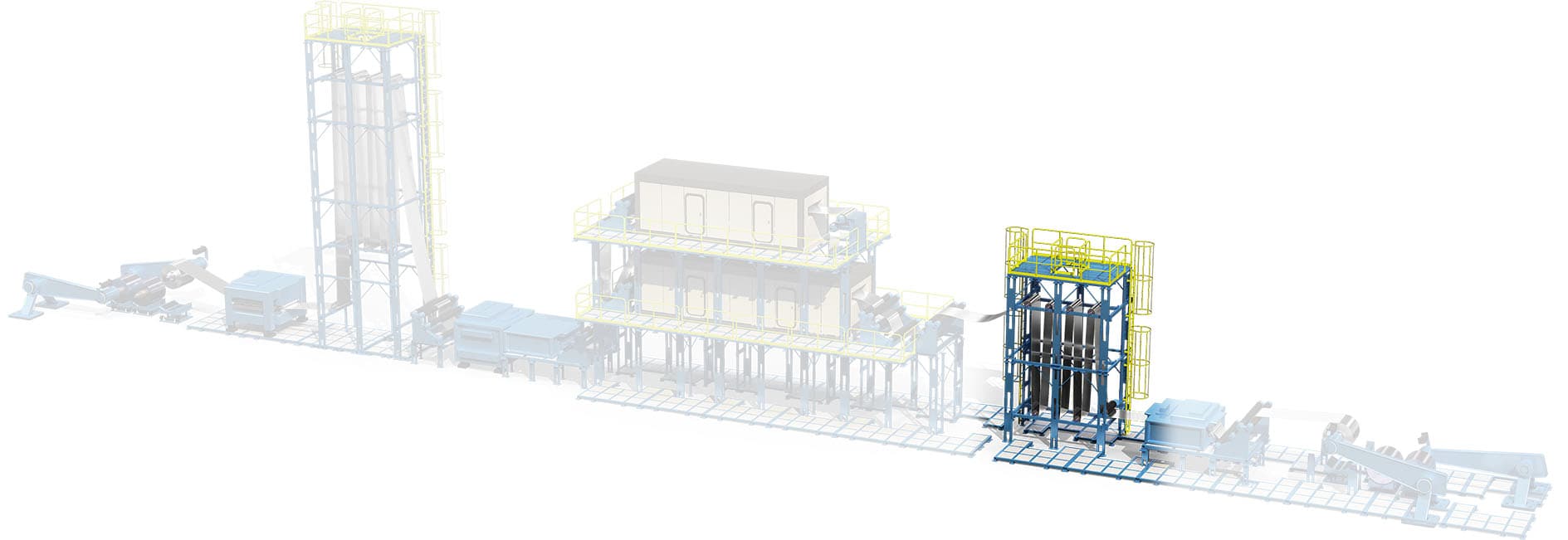

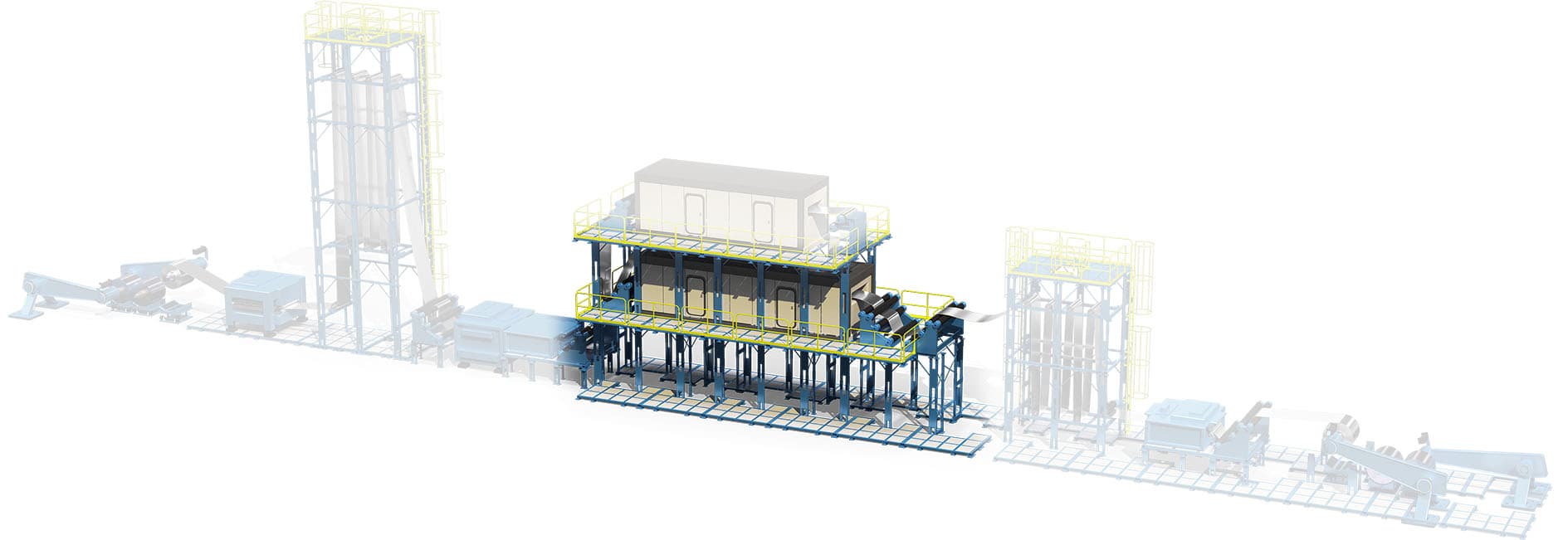

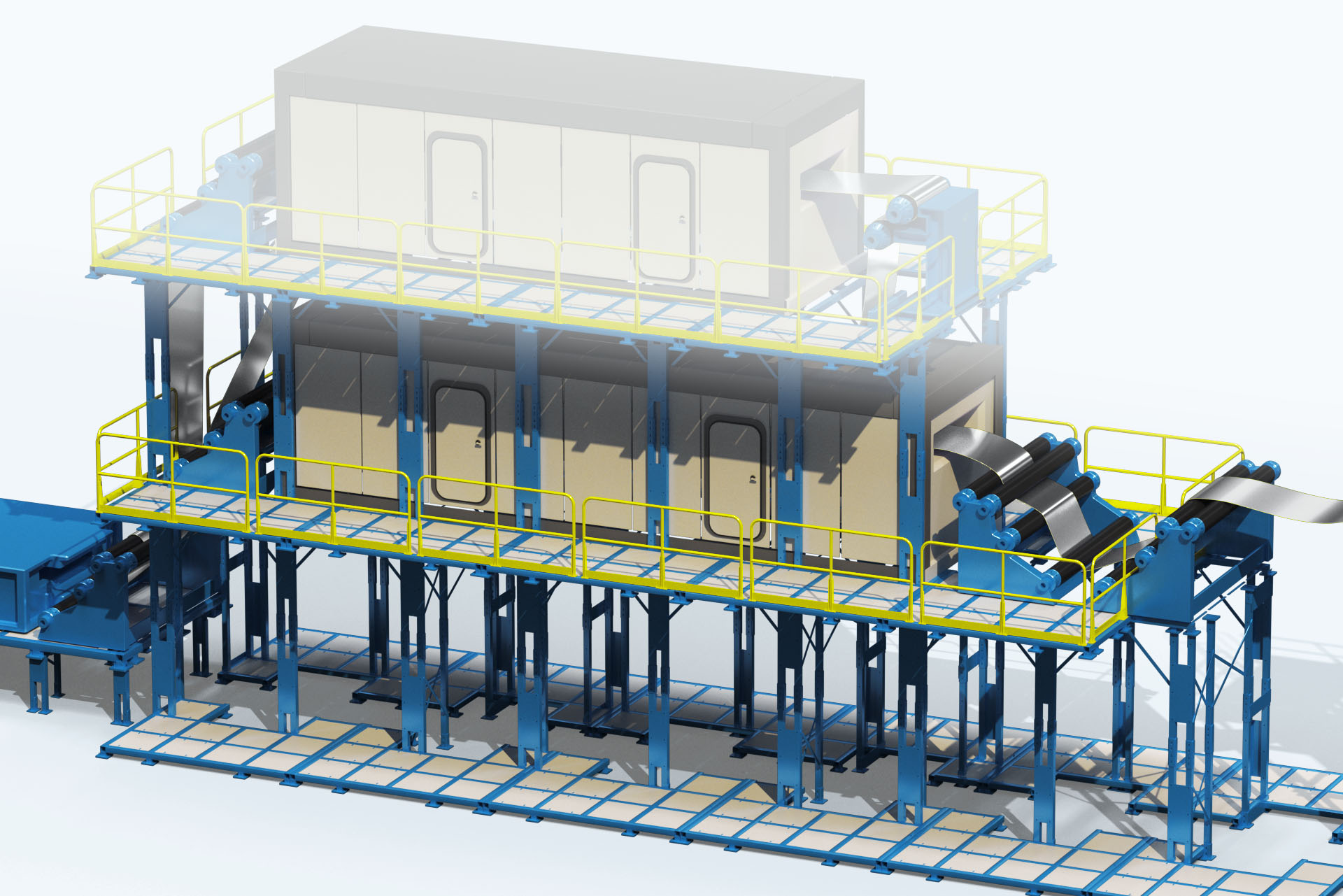

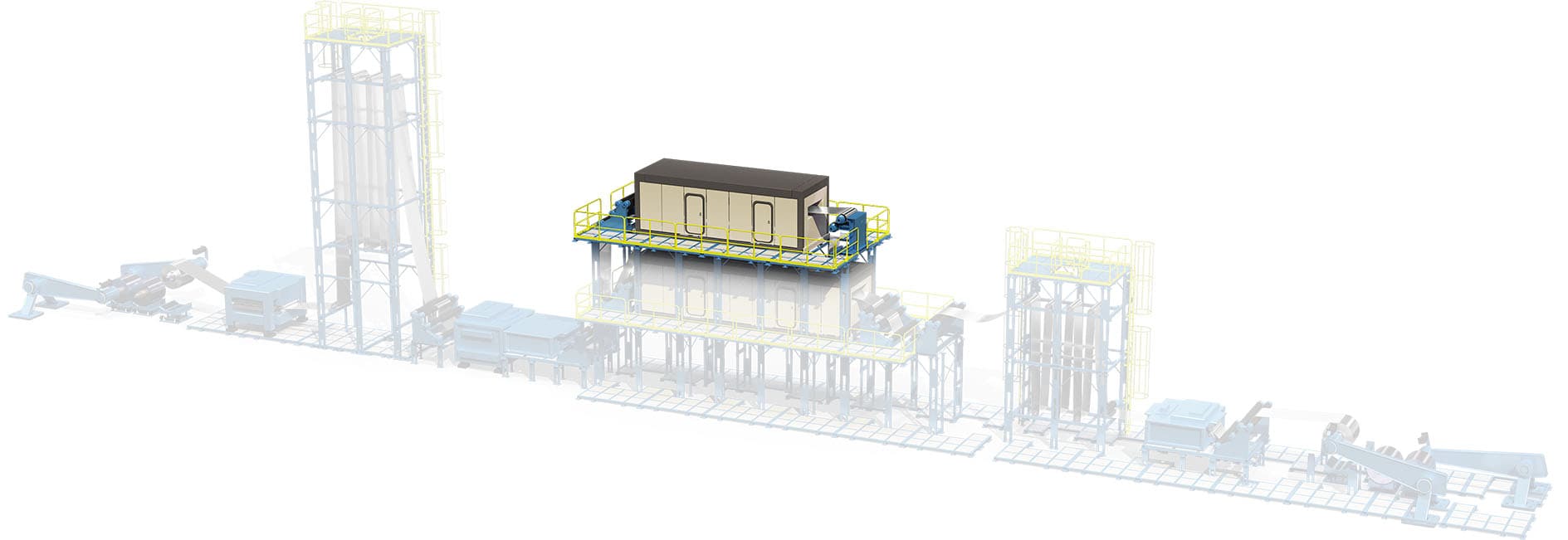

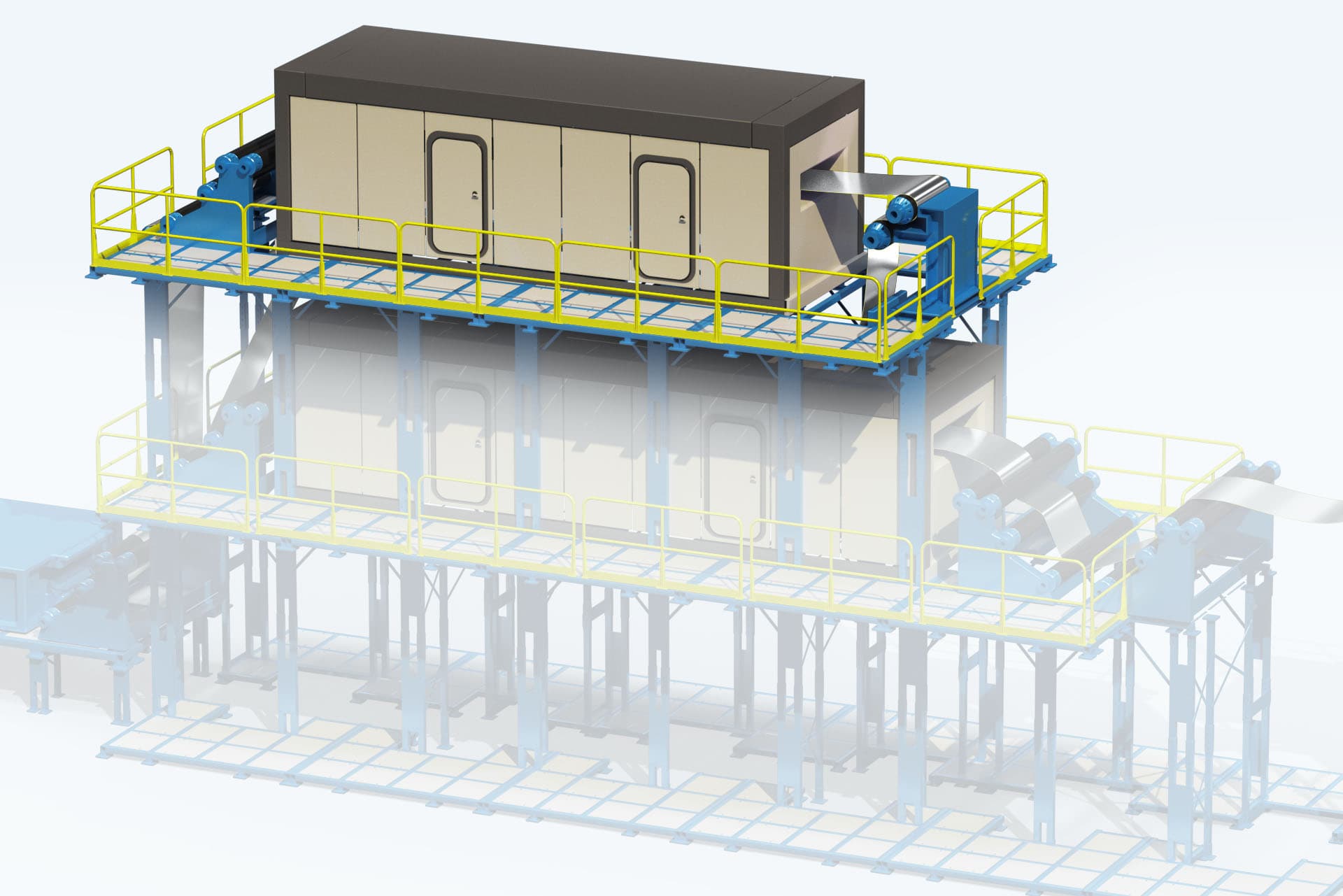

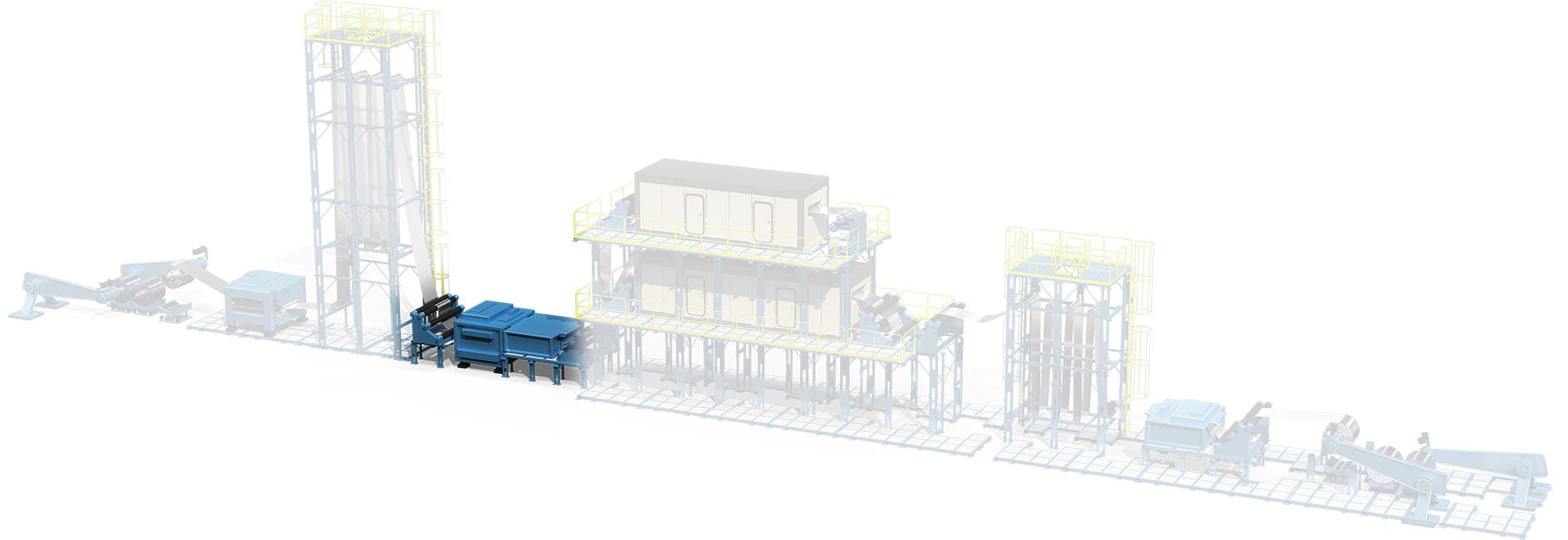

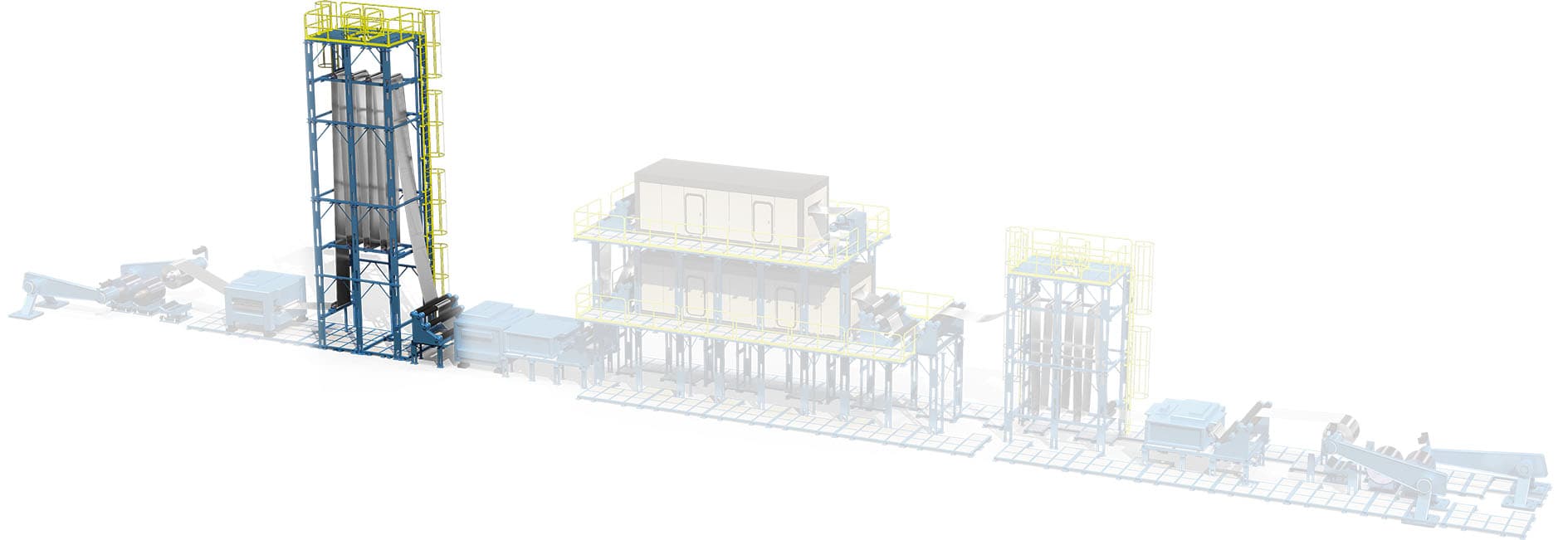

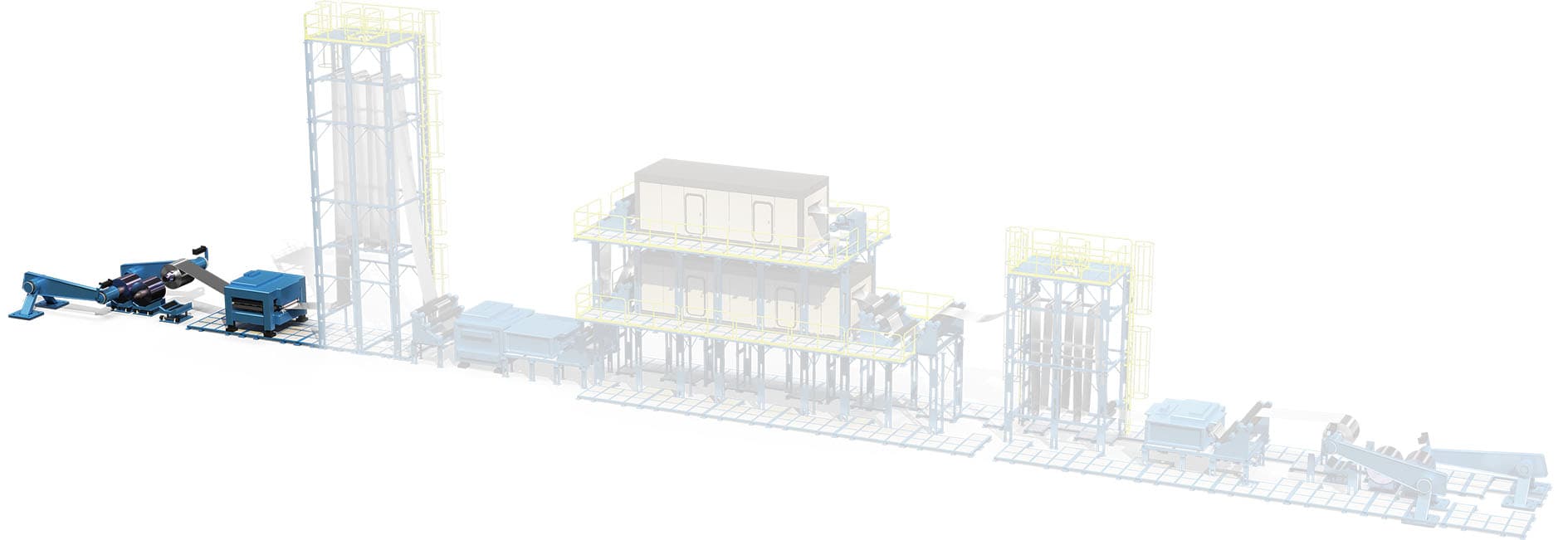

AZZ has an expansive network of powder coating facilities. Our state-of-the-art, highly automated operations are equipped for high-volume production with turnaround time in as little as 24 hours for all of the industries we serve.

With AZZ’s commitment to quality, we are able to meet and exceed the standards of a wide range of industries. These include but are not limited to Aerospace, Automotive, Architectural, Telecommunications, as well as Oil & Gas.

The best choice for decorative and functional finishes in powder coating

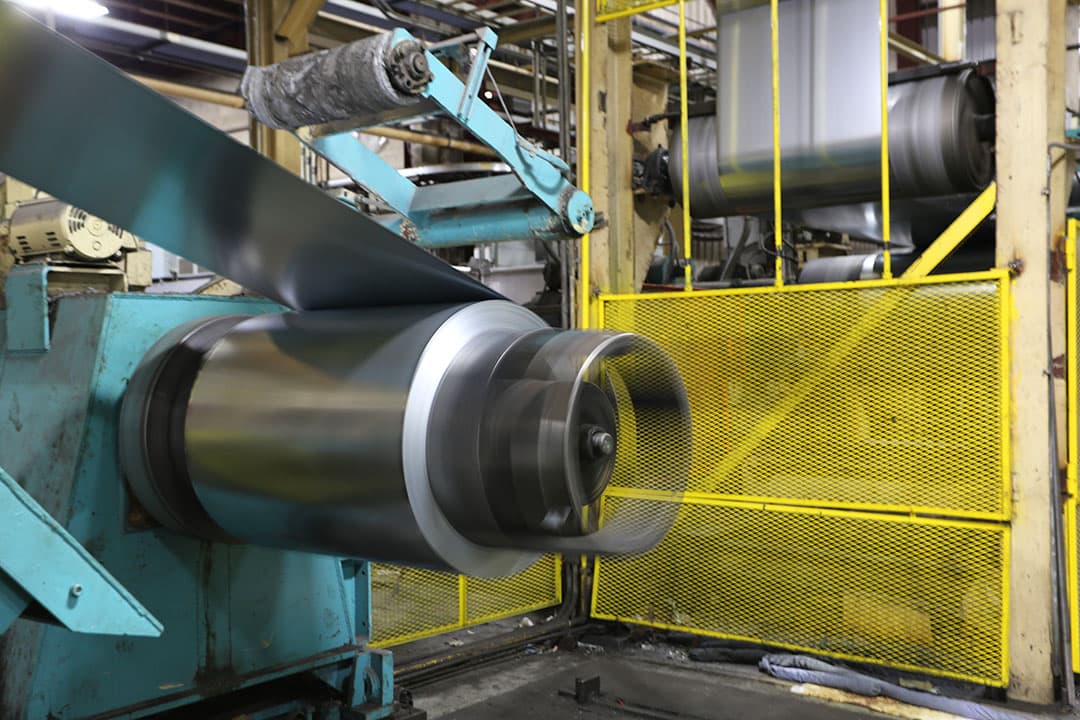

Our ISO 9001 Certified process and our constant never-ending focus on zero defects ensures a durable, attractive, long-lasting finish.

We have earned the following Quality Certifications:

- ISO 9001 (Quality Management)

- AS9100 (Aerospace Quality Management)

- NADCAP for Chemical Processing (Aerospace and Defense)

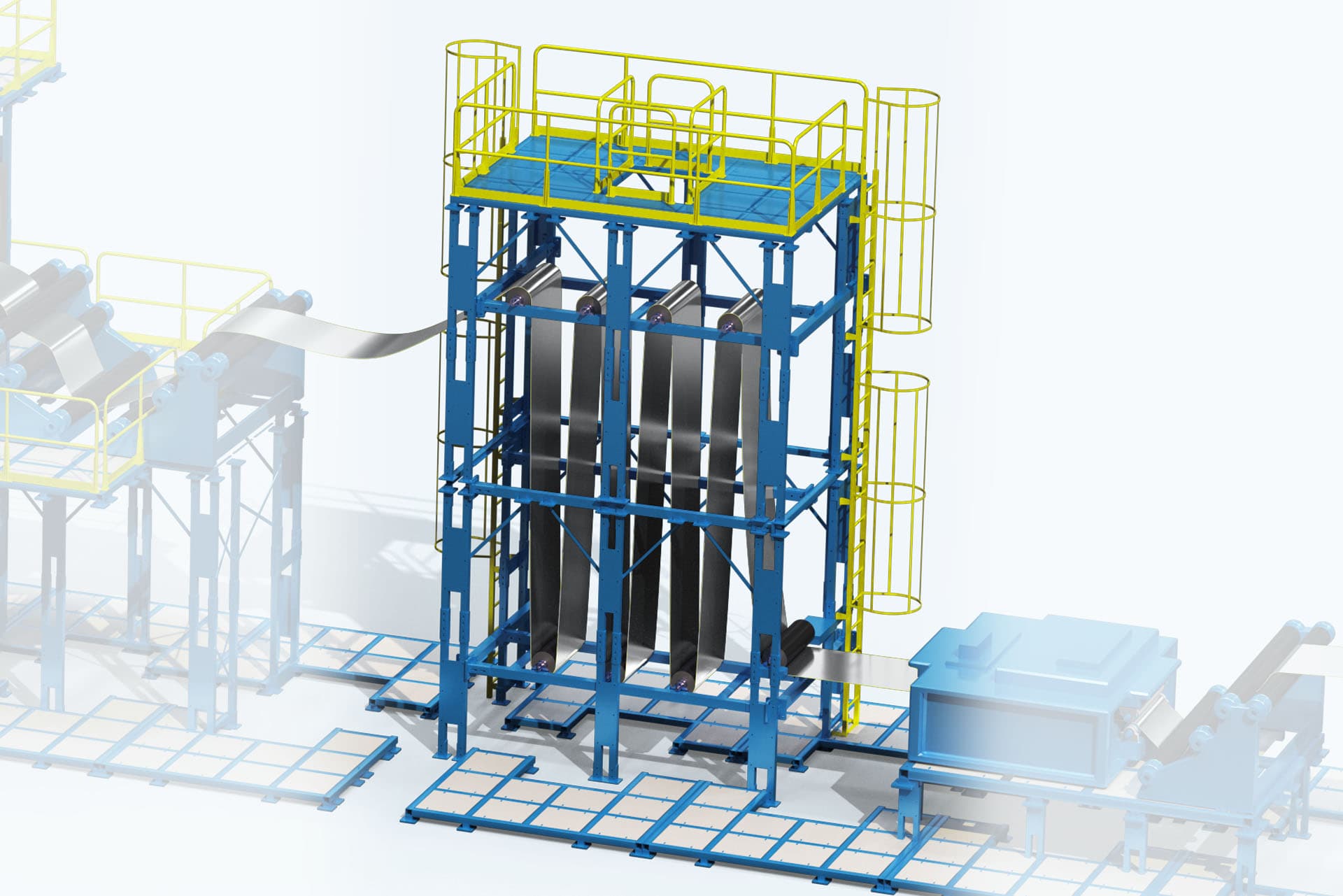

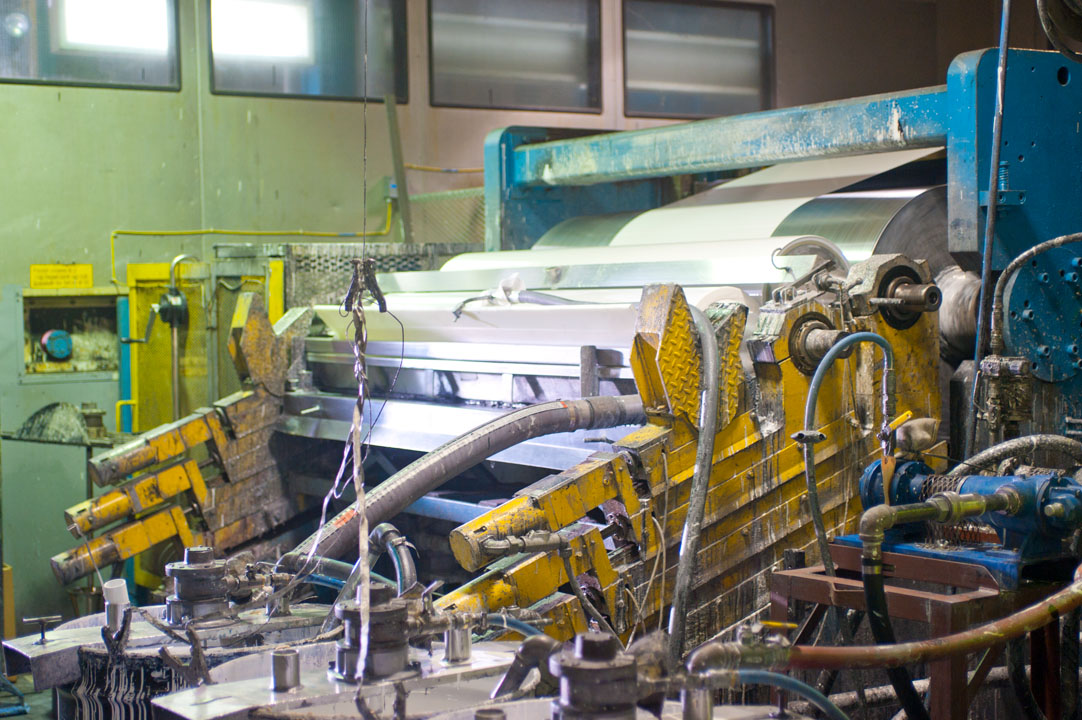

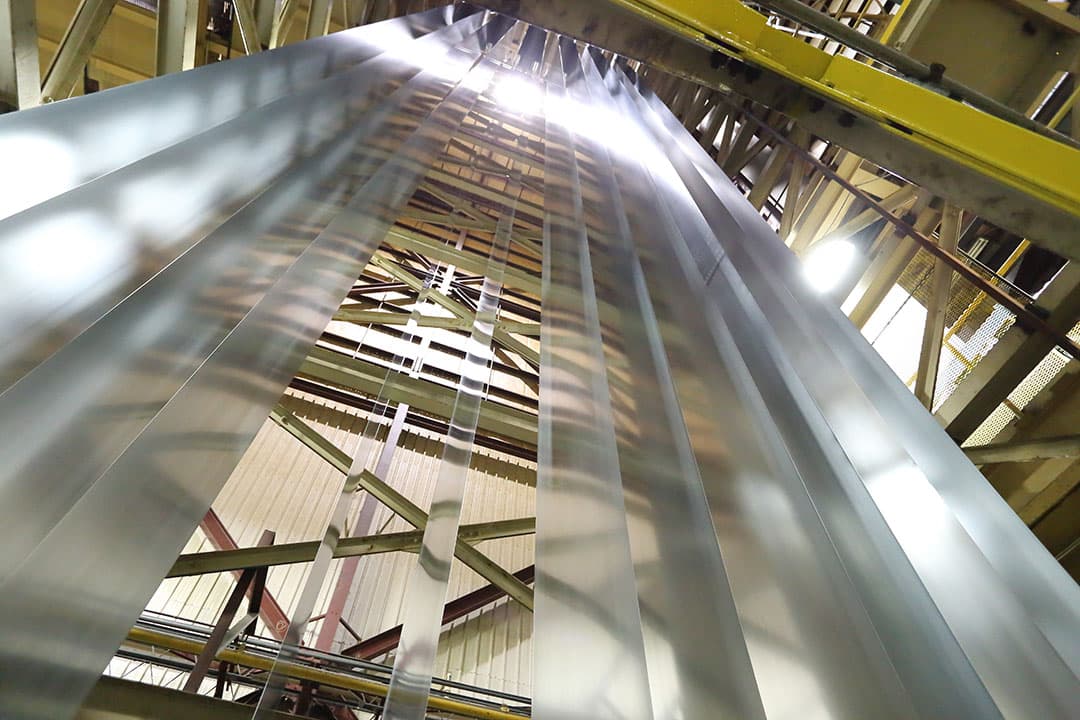

Our facilities can handle items of any size from small parts up to items 60 ft. in length

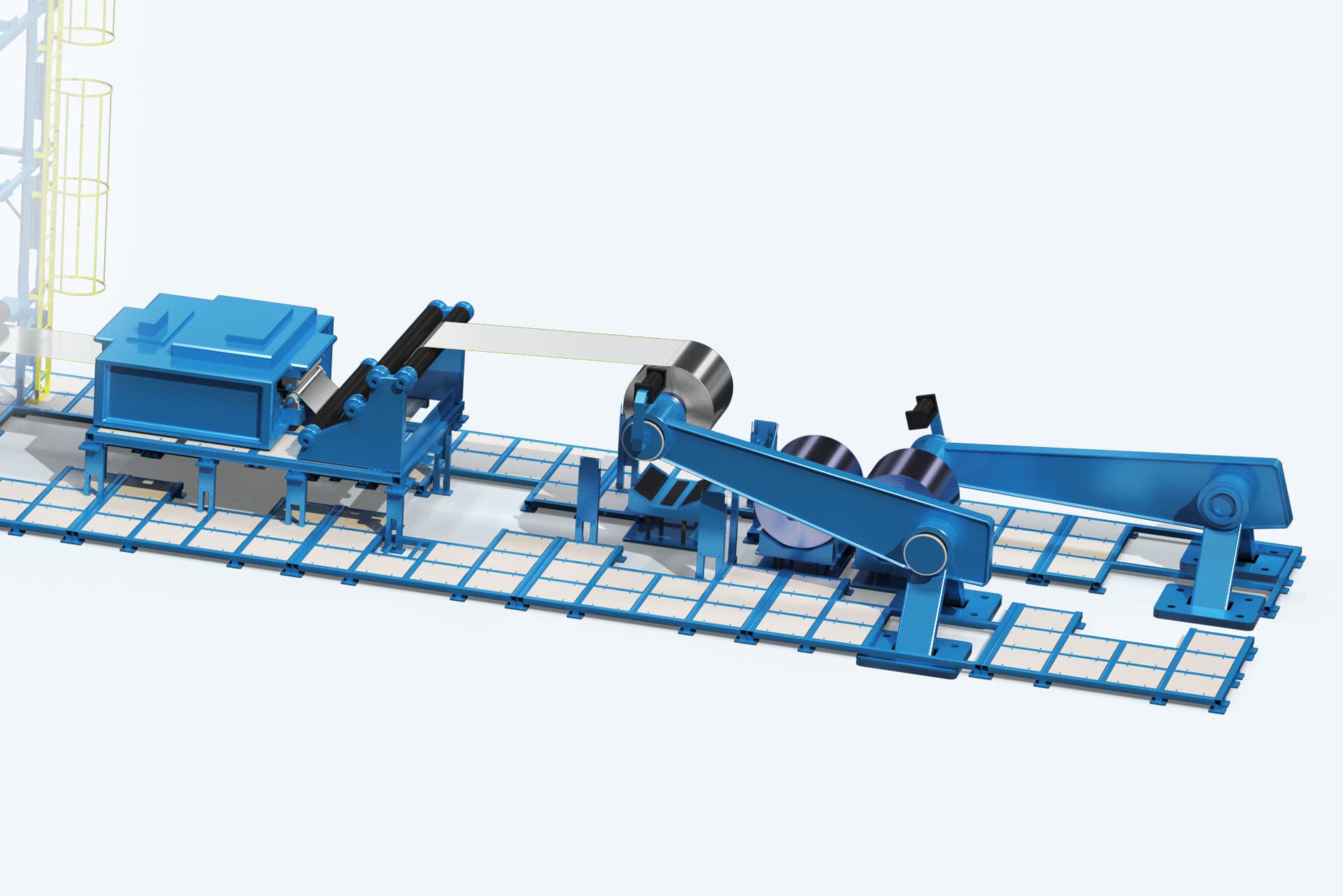

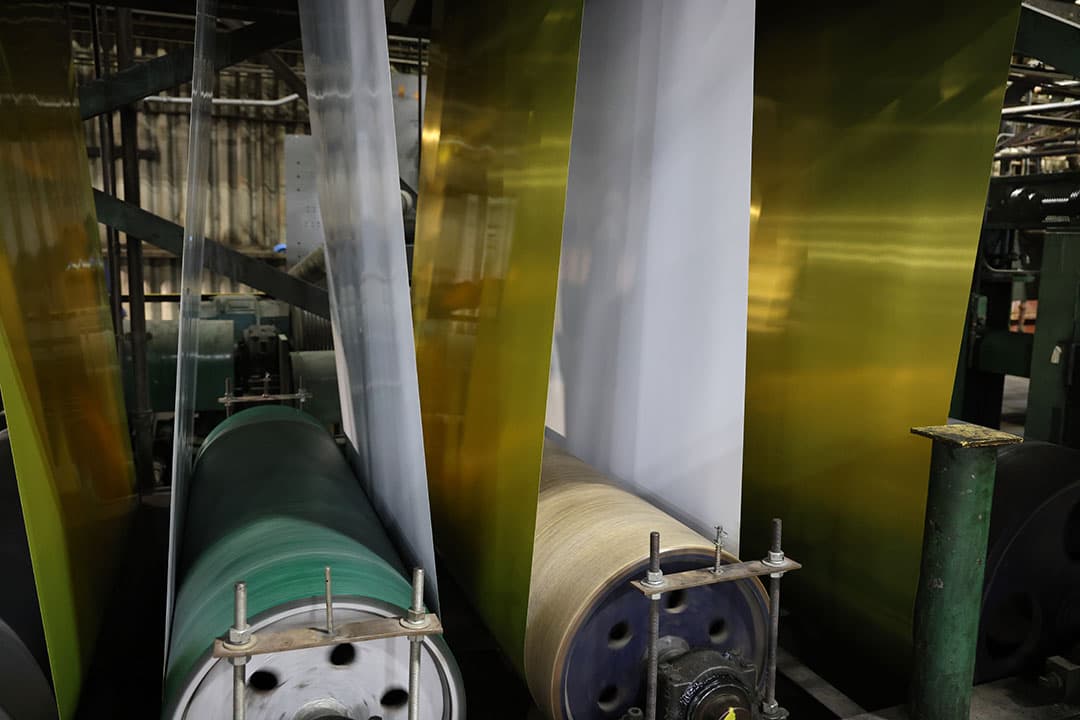

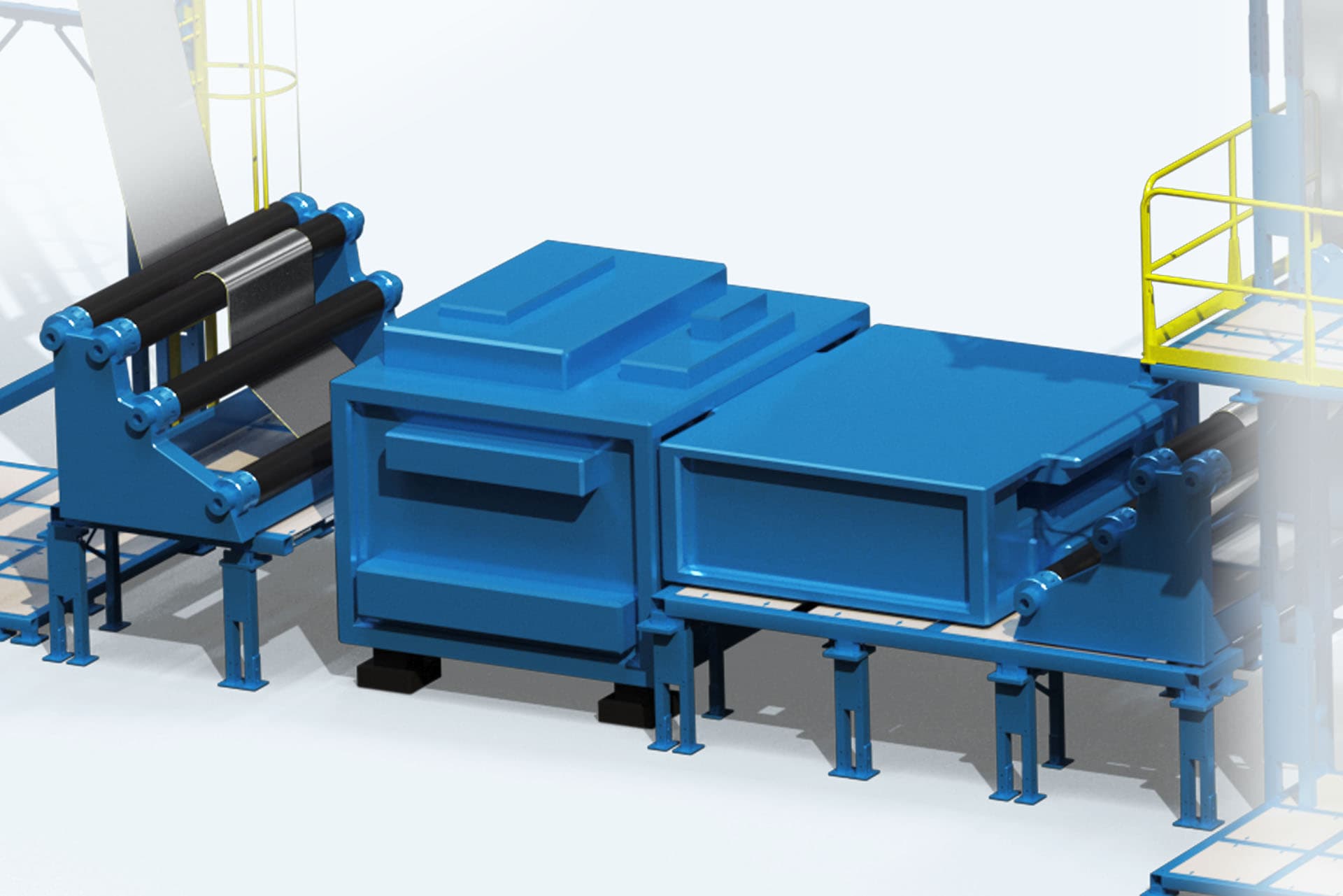

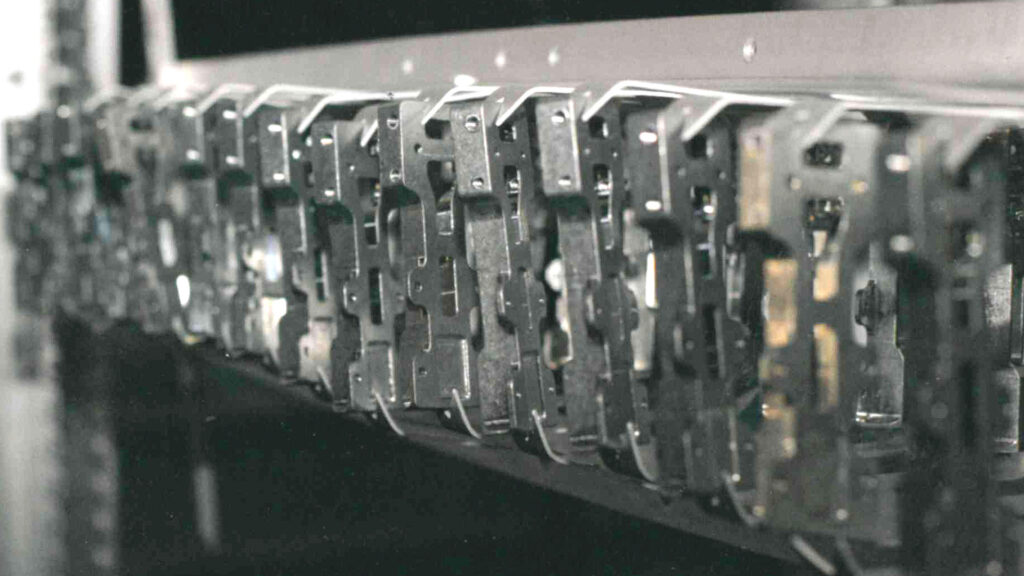

Our facilities utilize numerous conveyor lines, augmented by multiple batch lines to accommodate the powder coating of stampings, castings, extrusions, tubing and many other products. Every part goes through a 3 or 5-stage pretreatment washer and, when necessary, cleaned by hand.

Related Stories

AZZ Surface Technologies Provides the Durability of Powder Coating with Extensive Production Capabilities

AZZ Surface Technologies has a vast network of powder coating facilities offering durable corrosion protection to extend the life of application-critical components with an array of color and texture options for aesthetics and safety code requirements.

Related Case Study

Gas City’s Gas Derrick Street Signs

After years of being subjected to the cold Indiana winters, the appearance of the street signs were no longer ideal, and the community noticed.

More Surface Technologies

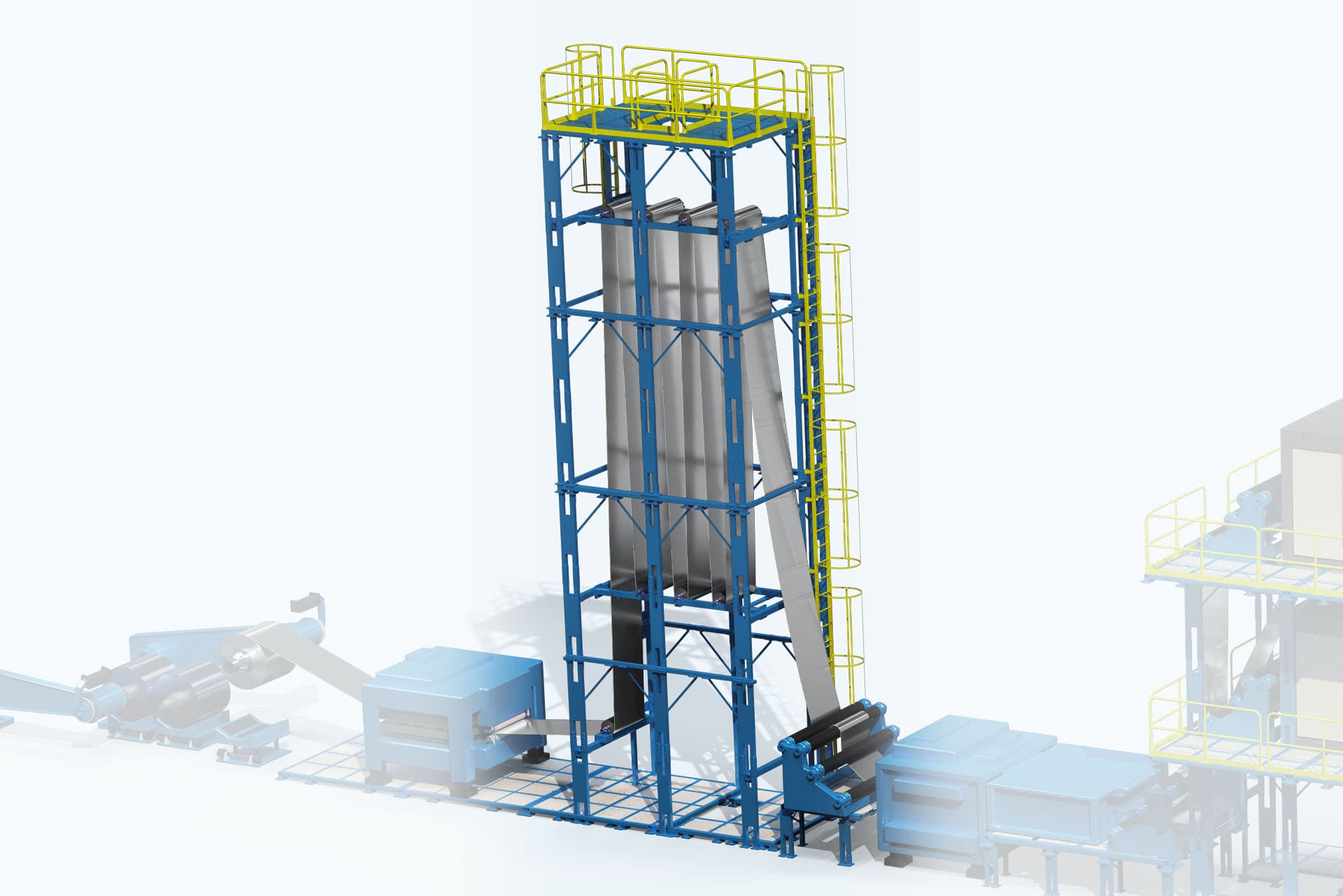

Duplex Coating

Duplex Coating

Optimal protection achieved through the synergies created by combining hot-dip galvanizing and powder or wet coating

Surface Prep

Surface Prep

Highly skilled experts provide sandblasting services, the surface preparation critical for a consistent, high-quality finish

Wet Coating

Wet Coating

Solvent-based paint formulations in an array of colors wet blasted for consistent coverage and corrosion protection