Creating exceptional material performance with seasoned expertise

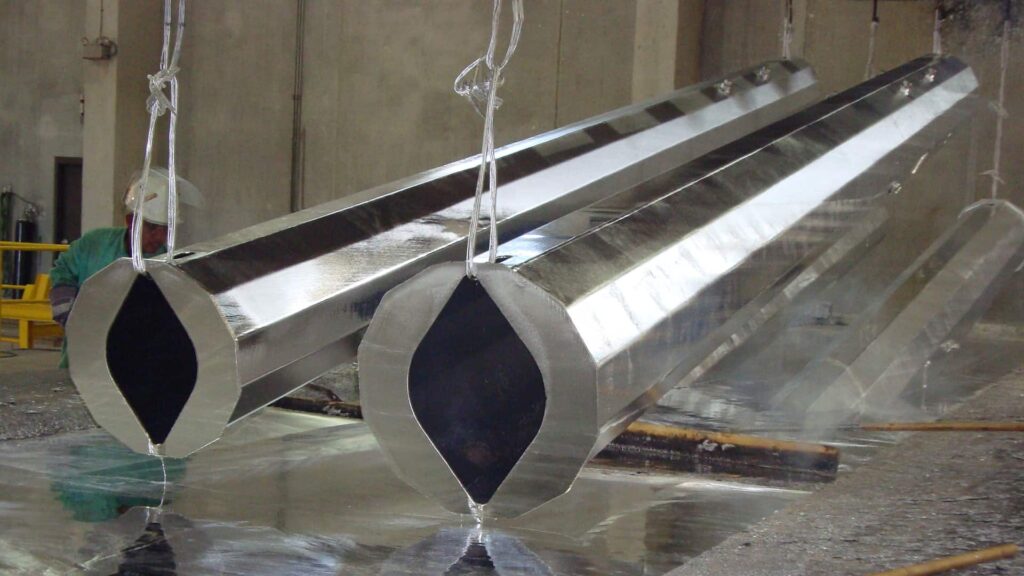

The galvanizing process has been refined and enhanced over the last 200 years. It represents the absolute best way to protect steel and ensure long-lasting, corrosion-free performance. Less costly than materials such as stainless steel and aluminum, galvanized steel delivers a significantly lower life cycle cost and requires no appreciable coating maintenance once installed.

A heavy footprint, except on the environment

In addition to being 100% recyclable, galvanized steel represents a sustainable material option that emits no volatile organic compounds or hazardous air pollutions in the treatment process. AZZ is committed to environmentally responsible operations, supporting LEED efforts through galvanized steel that contributes points toward certification. With 43 galvanizing locations throughout the U.S. and Canada, AZZ can help minimize transportation requirements while providing extensive resources available at the local level.

AZZ has broad industry experience, having performed hot-dip galvanizing for steel components that meet the performance requirements for a wide range of applications including:

- Agriculture

- Bridge & highway

- Construction

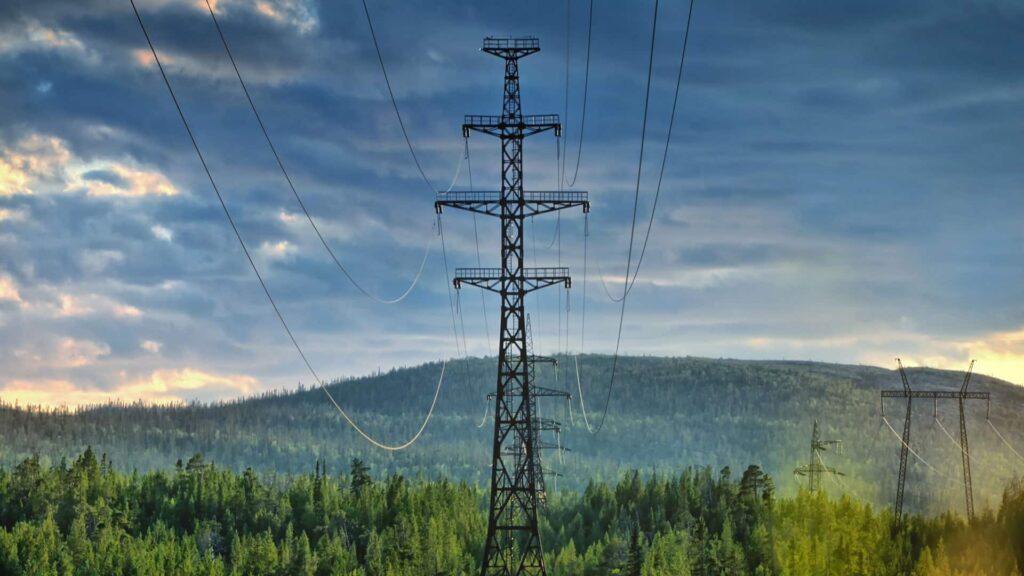

- Electrical utility

- Industrial

- Original equipment manufacturers

- Petrochemical

- Recreational

- Transportation

Contact Us

Downloads

Locations

Related Featured Story

The History of Galvanization Takes a Step Forward at AZZ

We have all heard of the galvanization of steel, but have you ever wondered how and why it’s done?

Related Case Study

No Results Found

The posts you requested could not be found. Try changing your module settings or create some new posts.

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Hot-Dip Galvanizing Process

A tested and proven galvanizing process ideal for modern applications

Spin Galvanizing

Cost-effective corrosion protection for small to mid-sized steel components