GalvXtra

GalvXtra

Formulated for superior coating performance

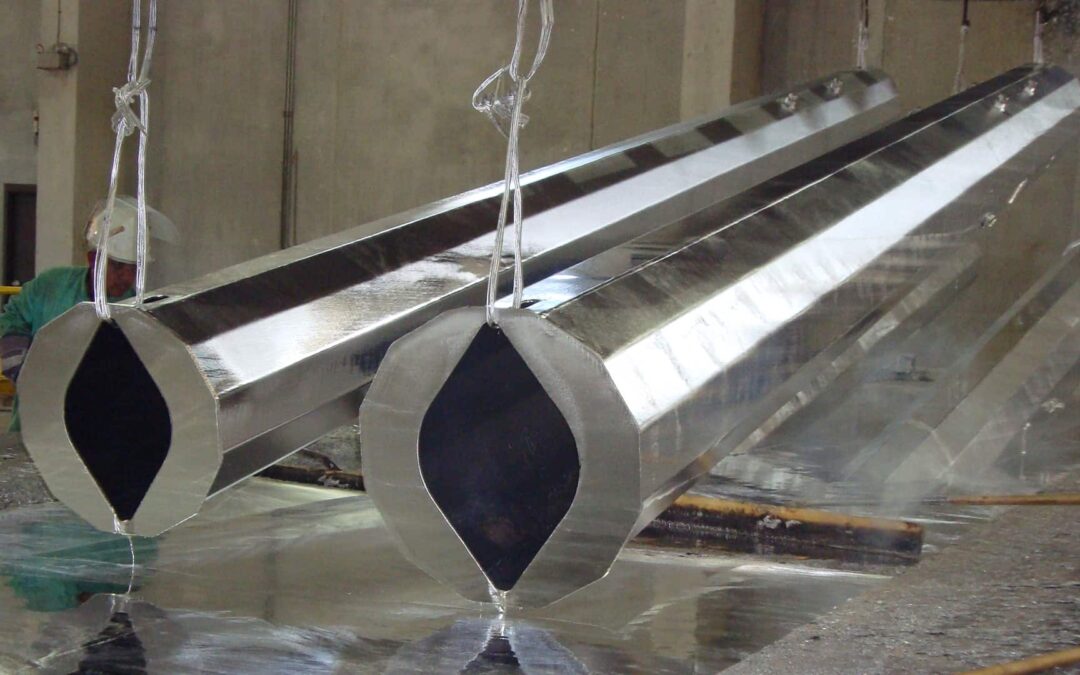

To ensure the highest performance from galvanized steel, AZZ utilizes a proprietary formulation of molten metals. The GalvXtra® formulation has been field tested and proven to provide a more uniform coating and an enduring finish through the resistance of the reaction of deoxidized steel to the molten zinc. GalvXtra meets international ASTM quality standards A123, ASTM A153, and ASTM B6 for zinc coatings on ferrous materials.

AZZ’s environmentally friendly, proprietary galvanizing process does not emit volatile organic compounds or hazardous air pollutants, and the use of sustainable, 100% recyclable galvanized steel as a construction material qualifies as a green building practice eligible for certification points under the Leadership in Energy and Environmental Design (LEED) rating system.

Contact Us

Downloads

Locations

Related Featured Story

No Results Found

The posts you requested could not be found. Try changing your module settings or create some new posts.

More

Accreditations

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Business & Consumer Products

Business & Consumer Products

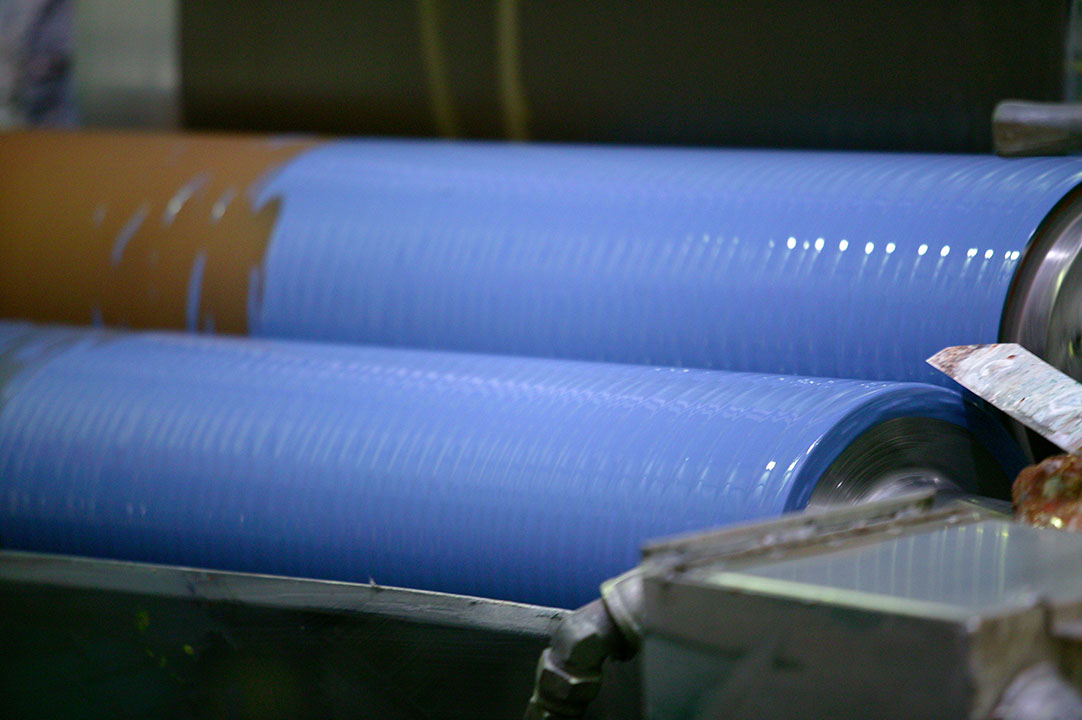

Performance-oriented coatings and film laminates for diverse applications

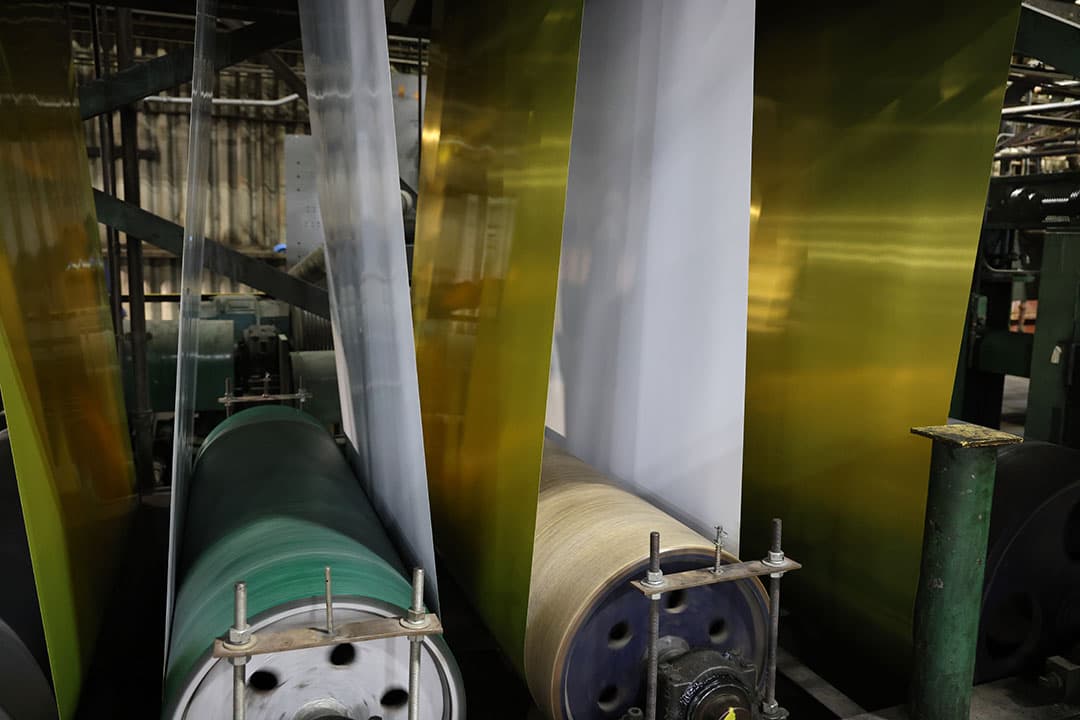

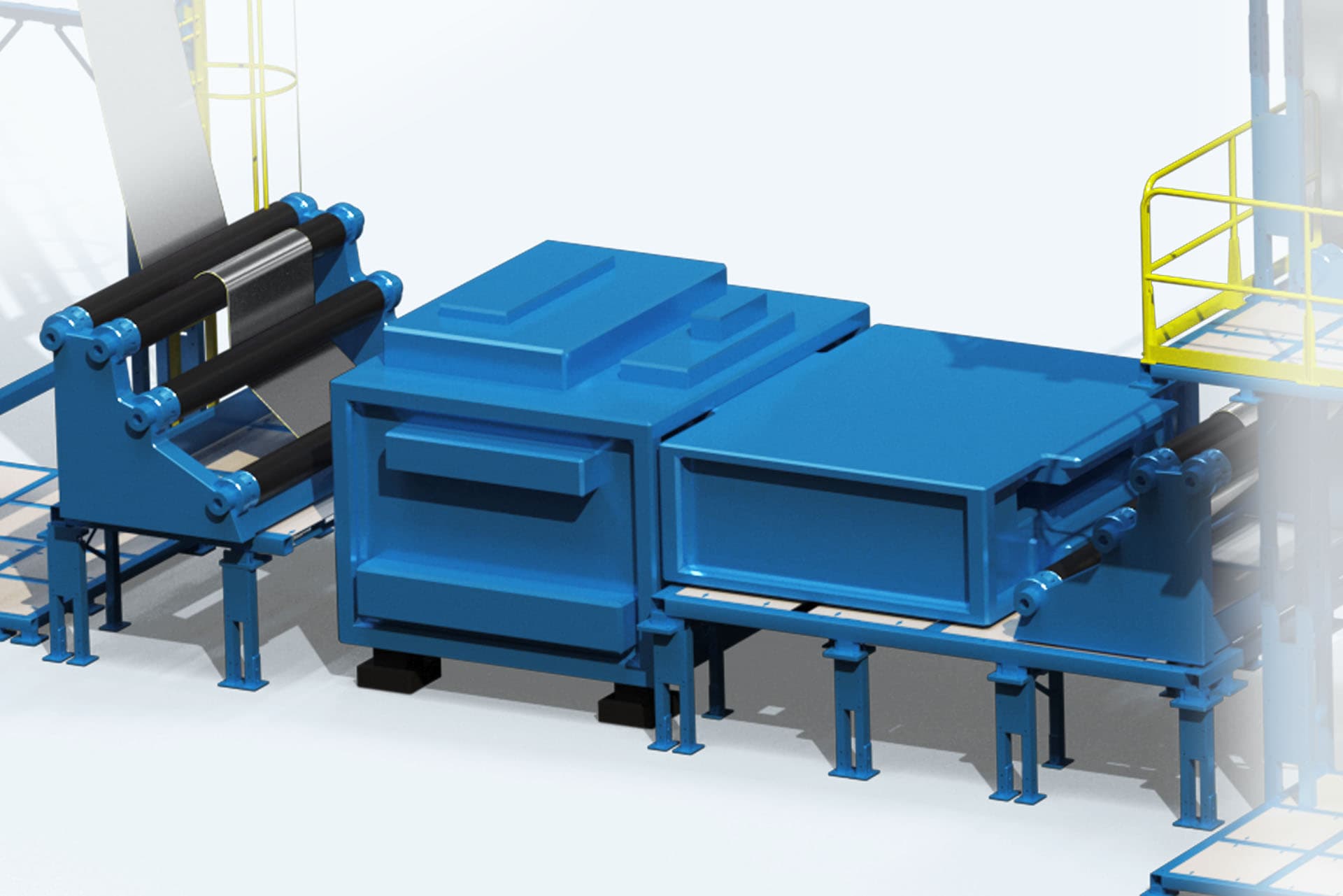

Cleaning & Pretreating

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products

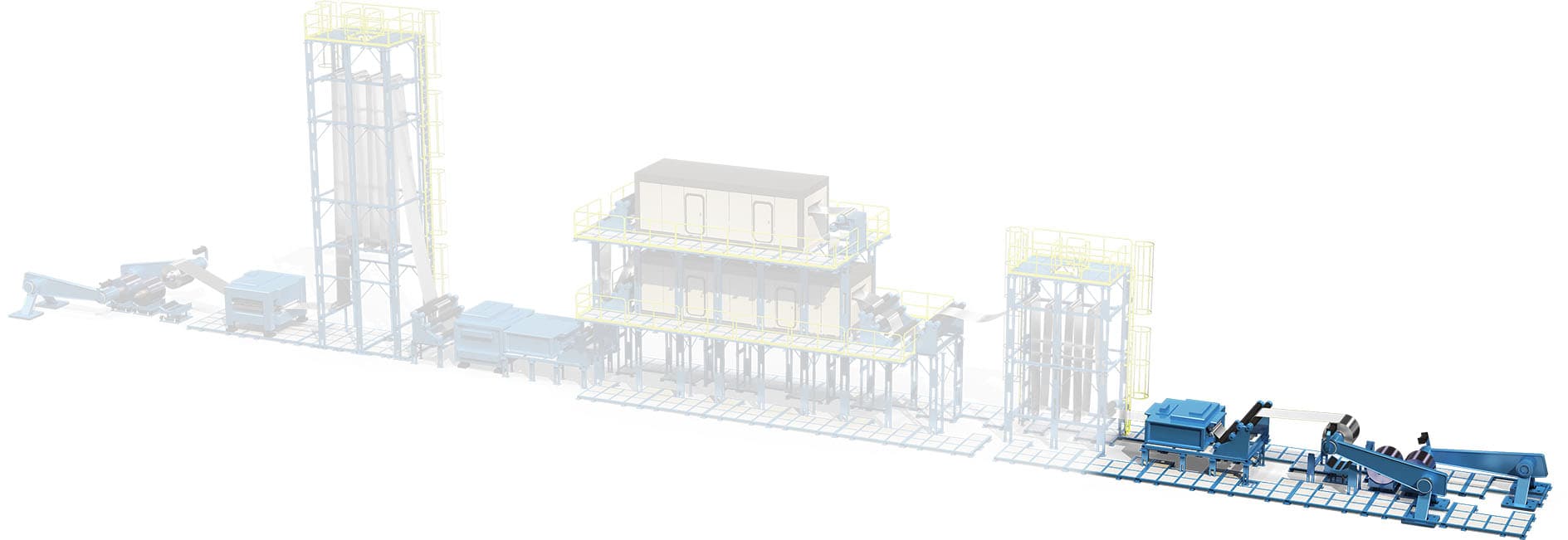

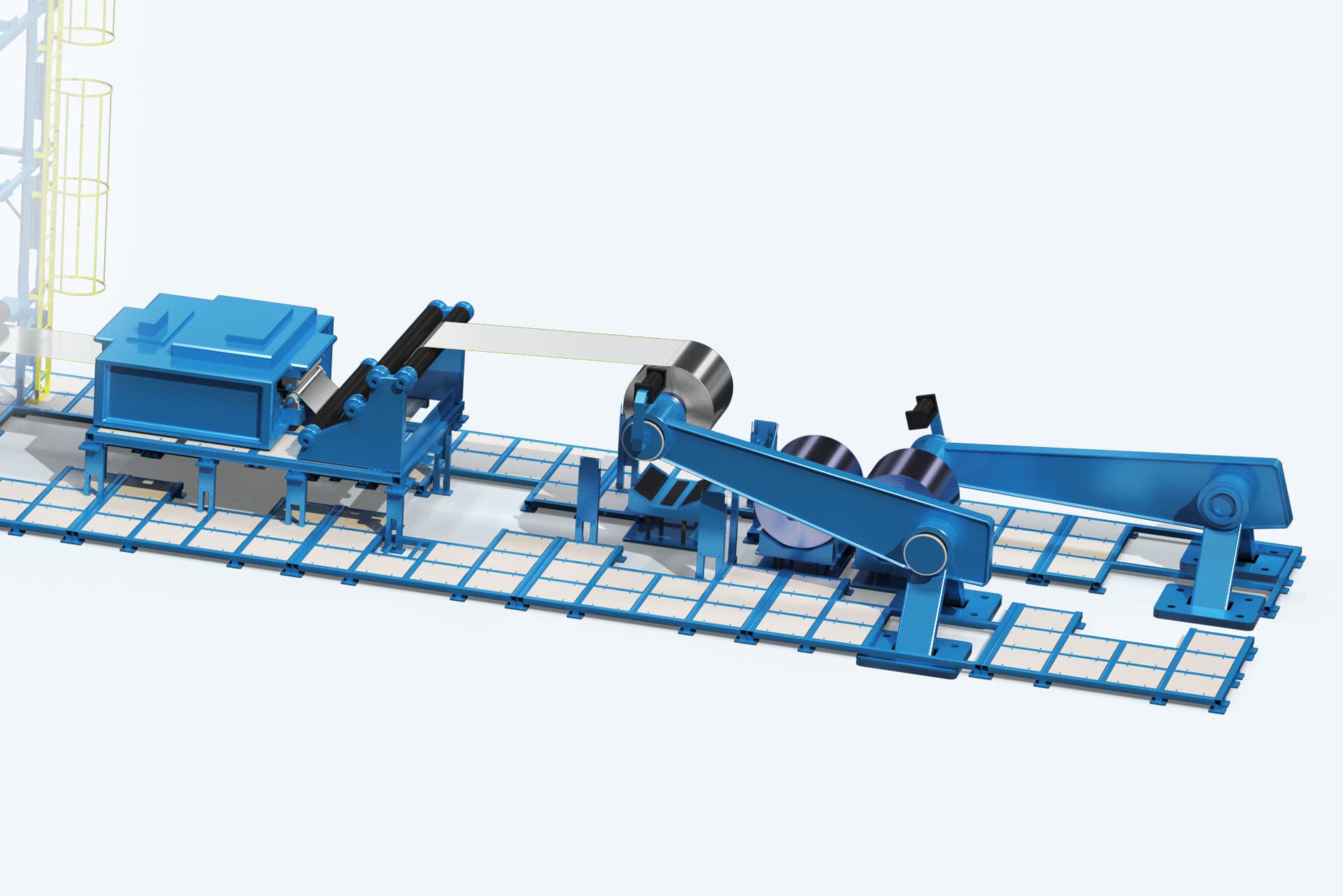

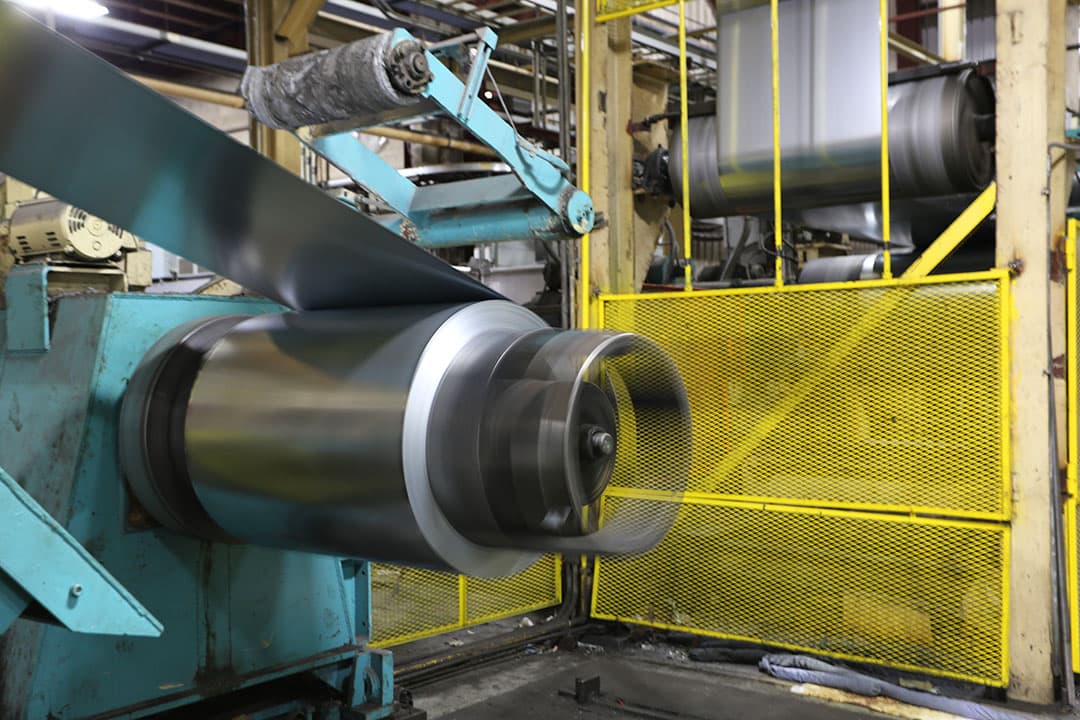

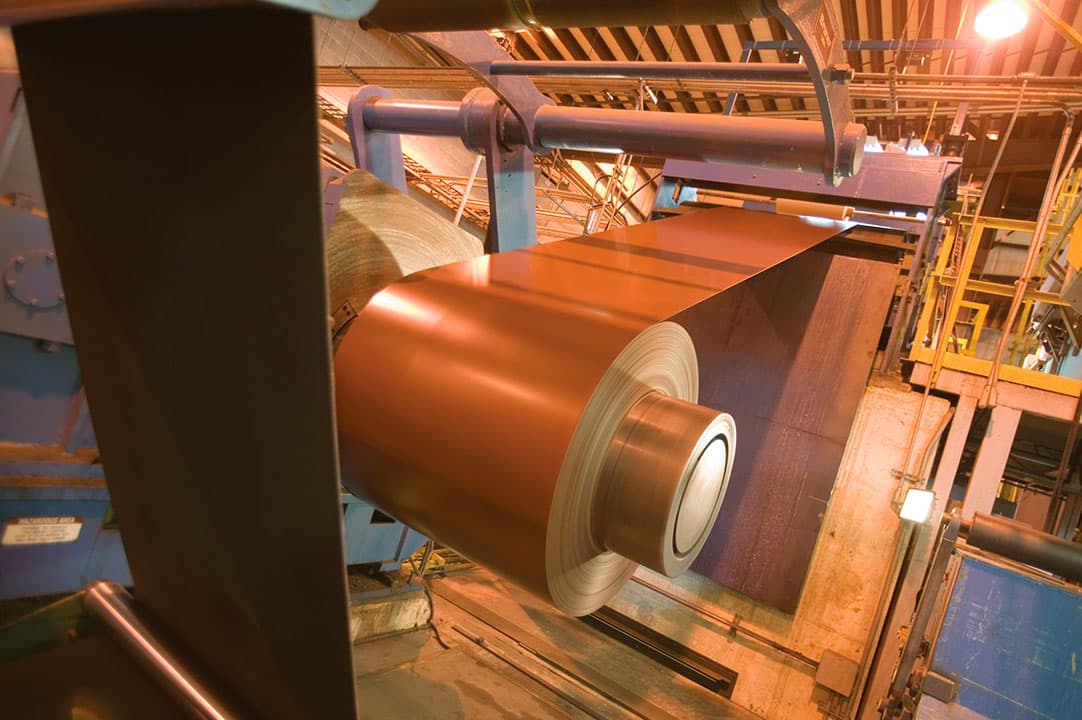

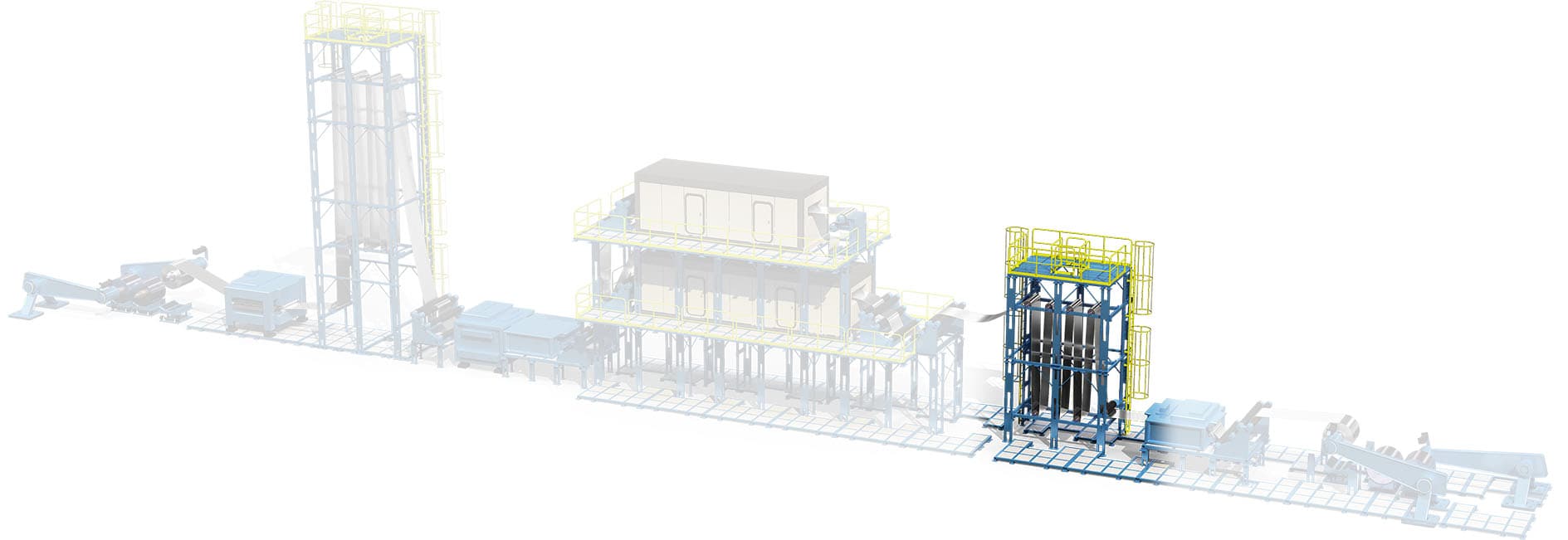

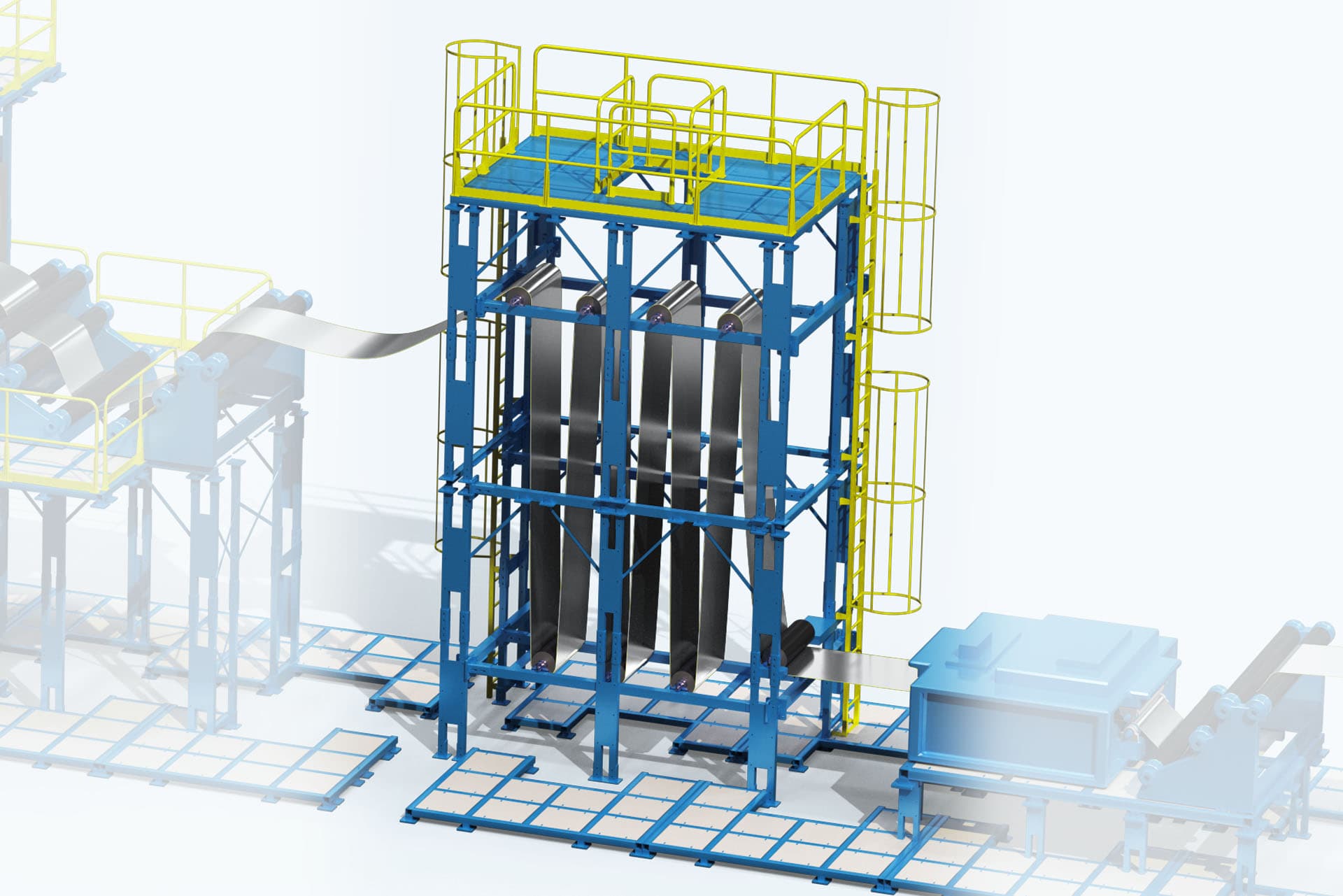

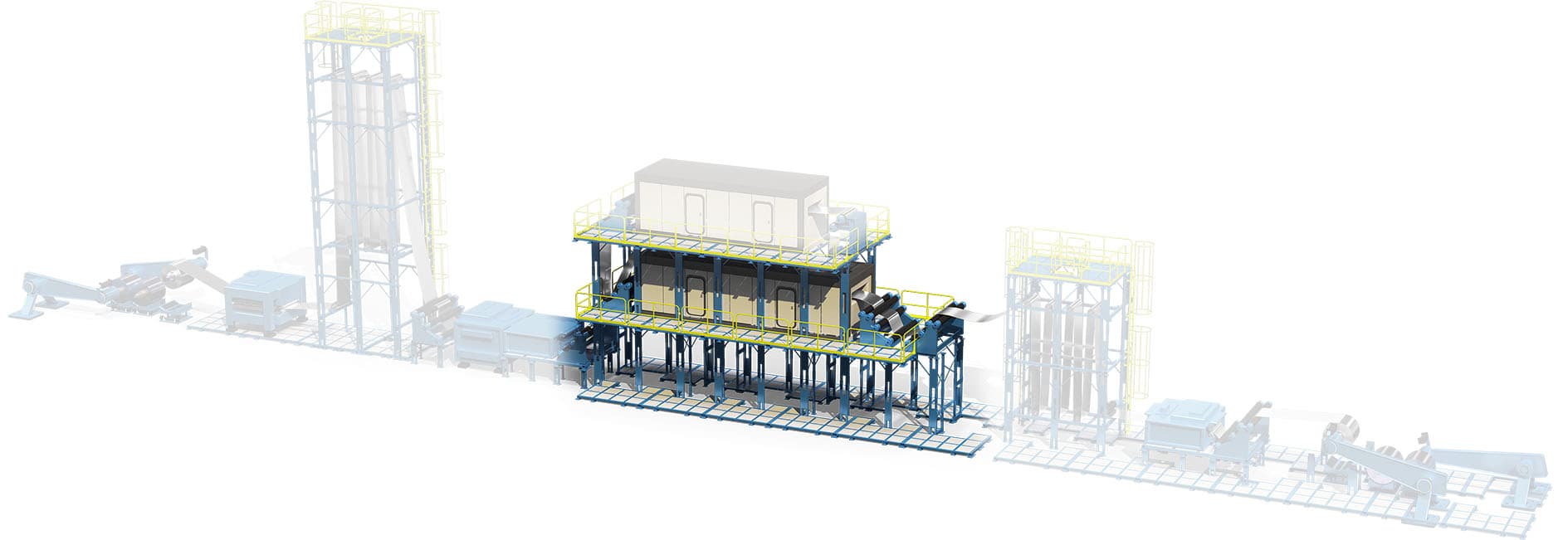

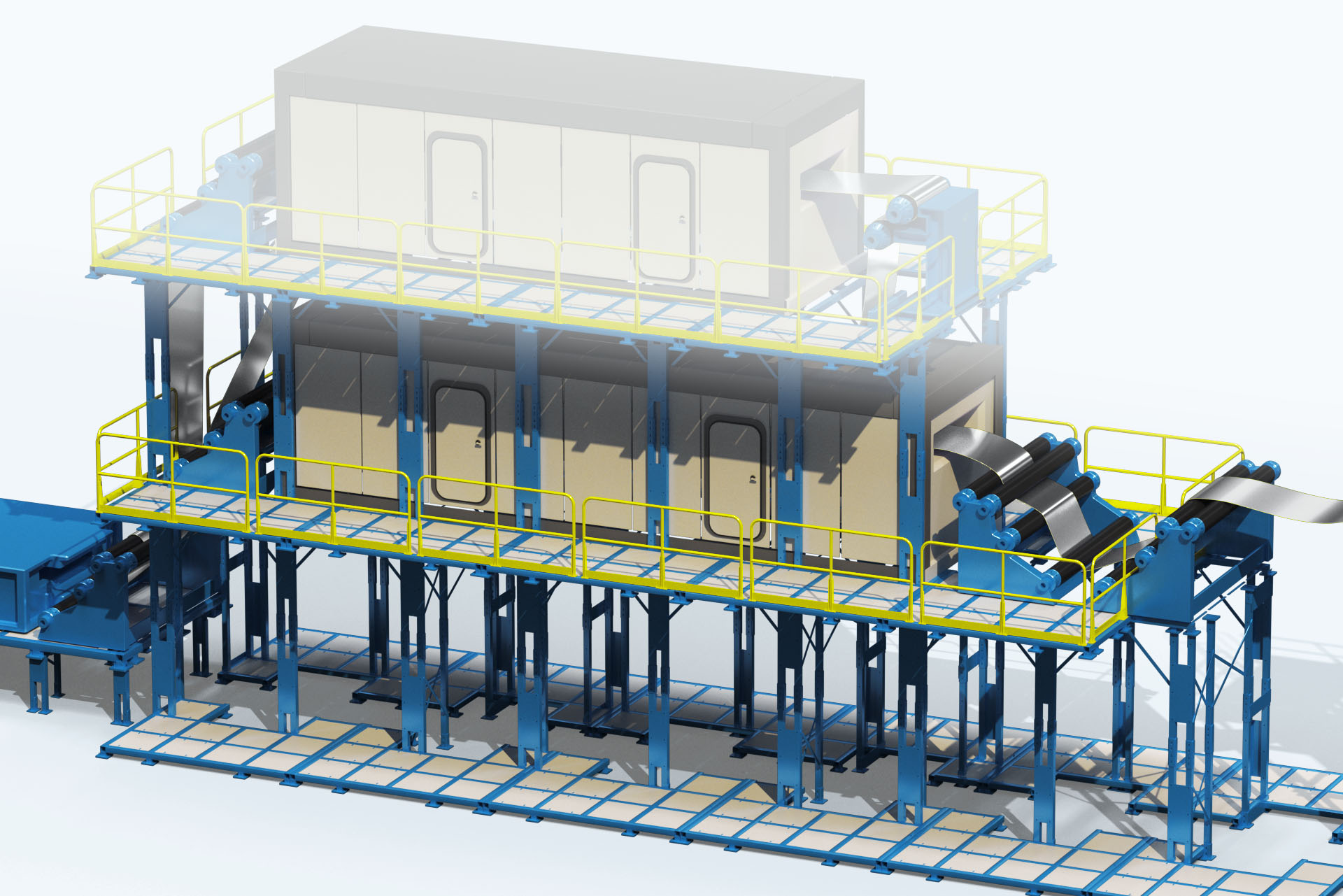

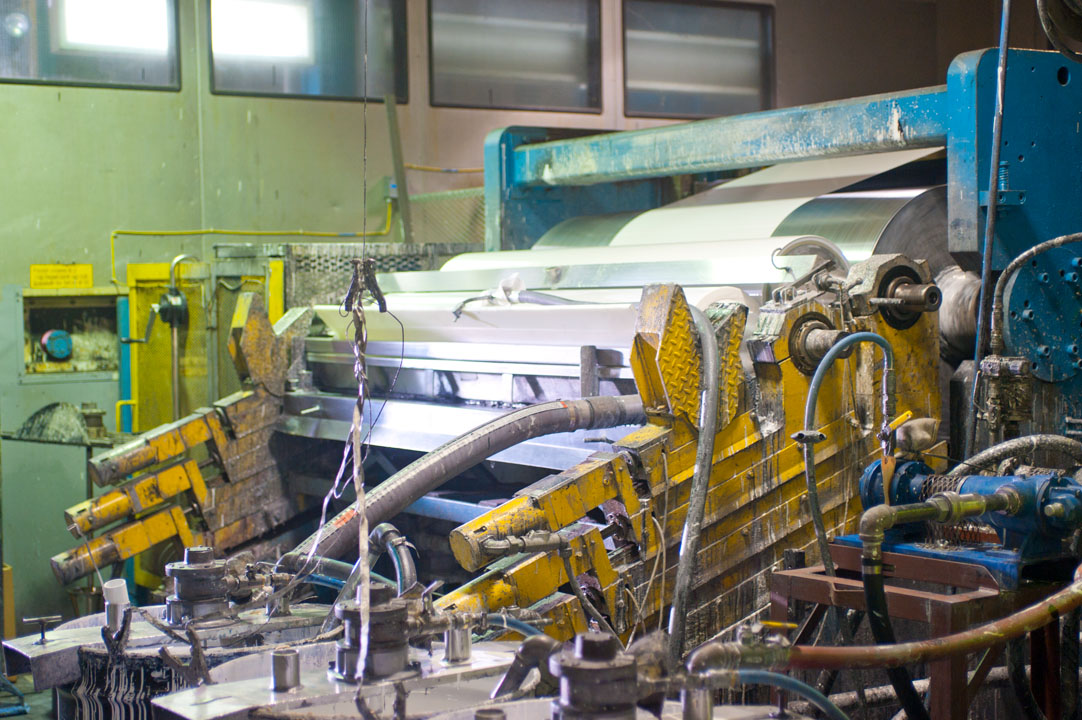

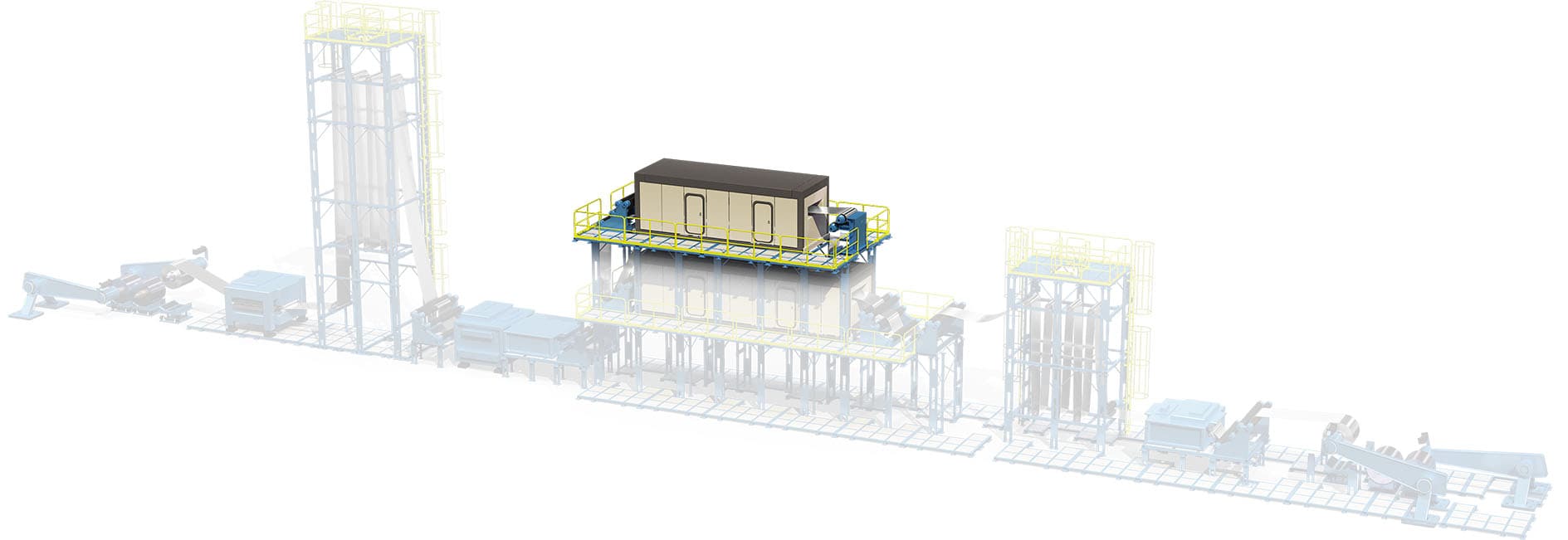

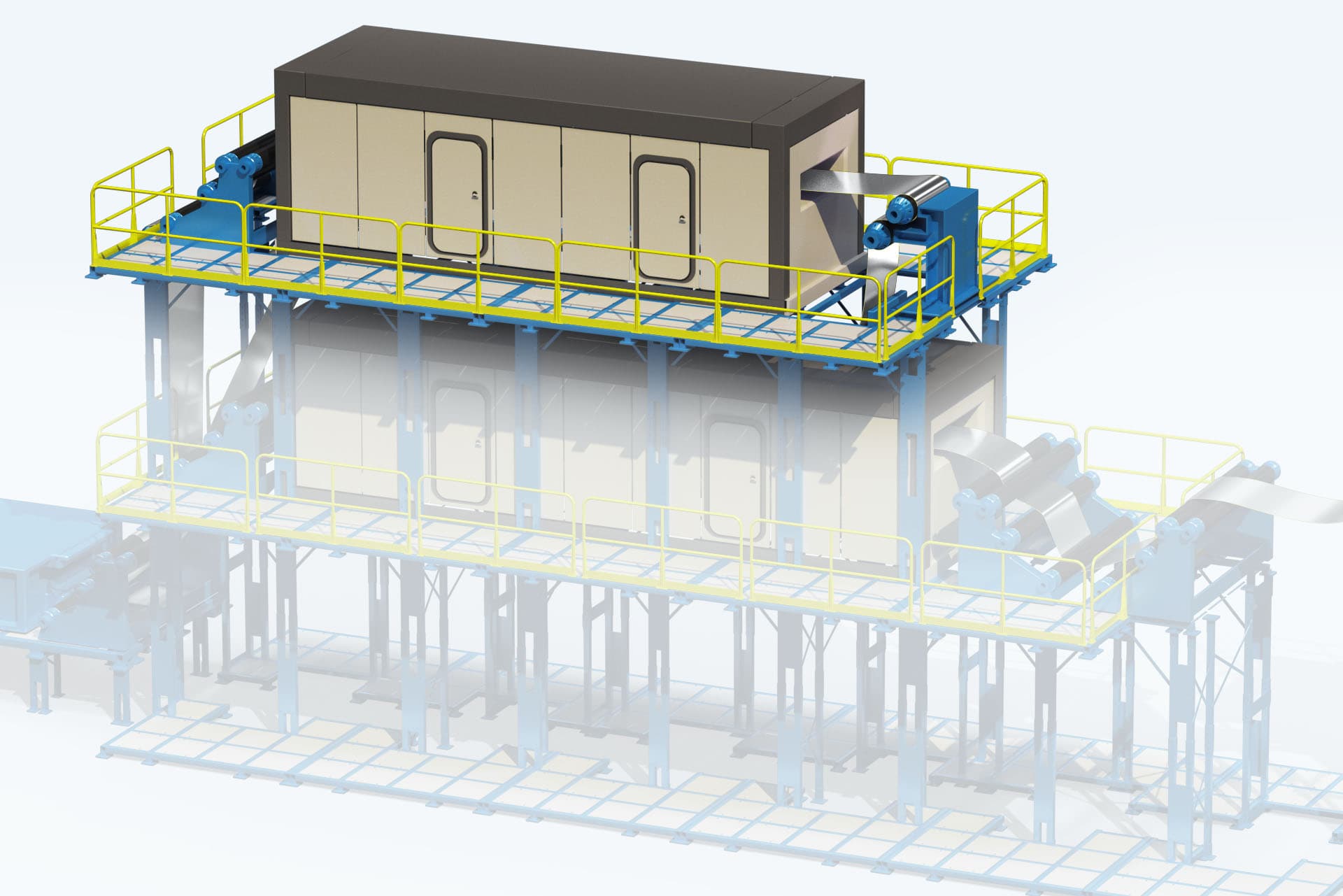

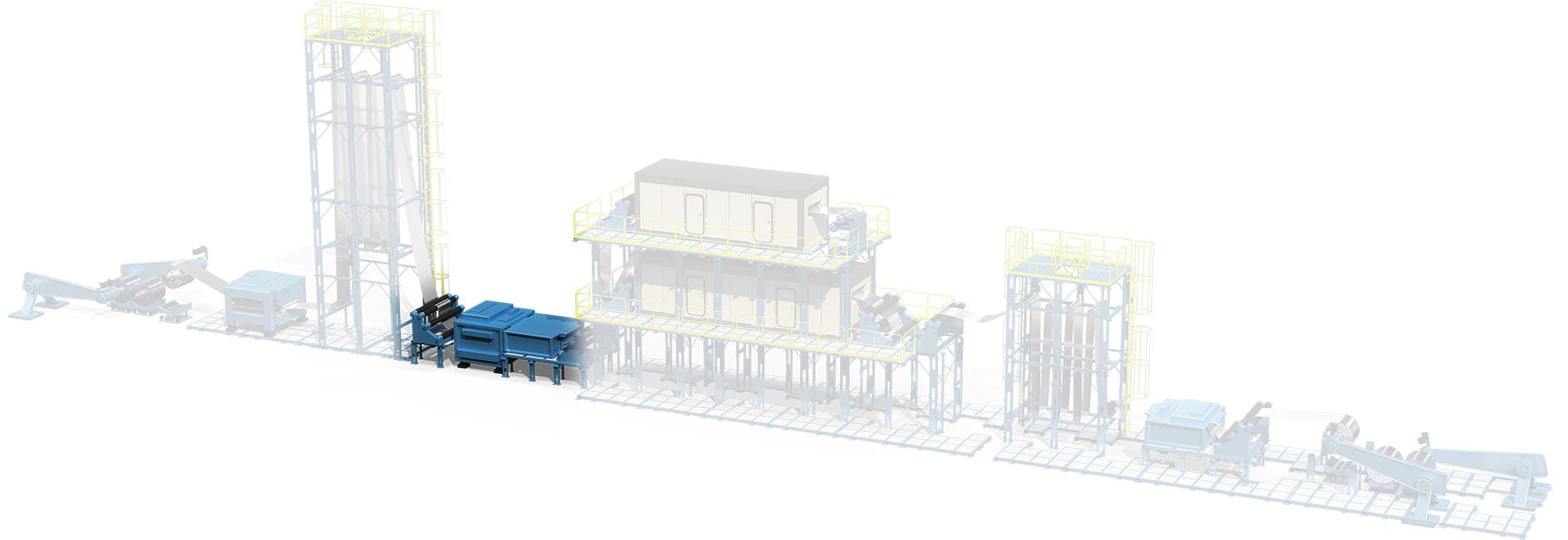

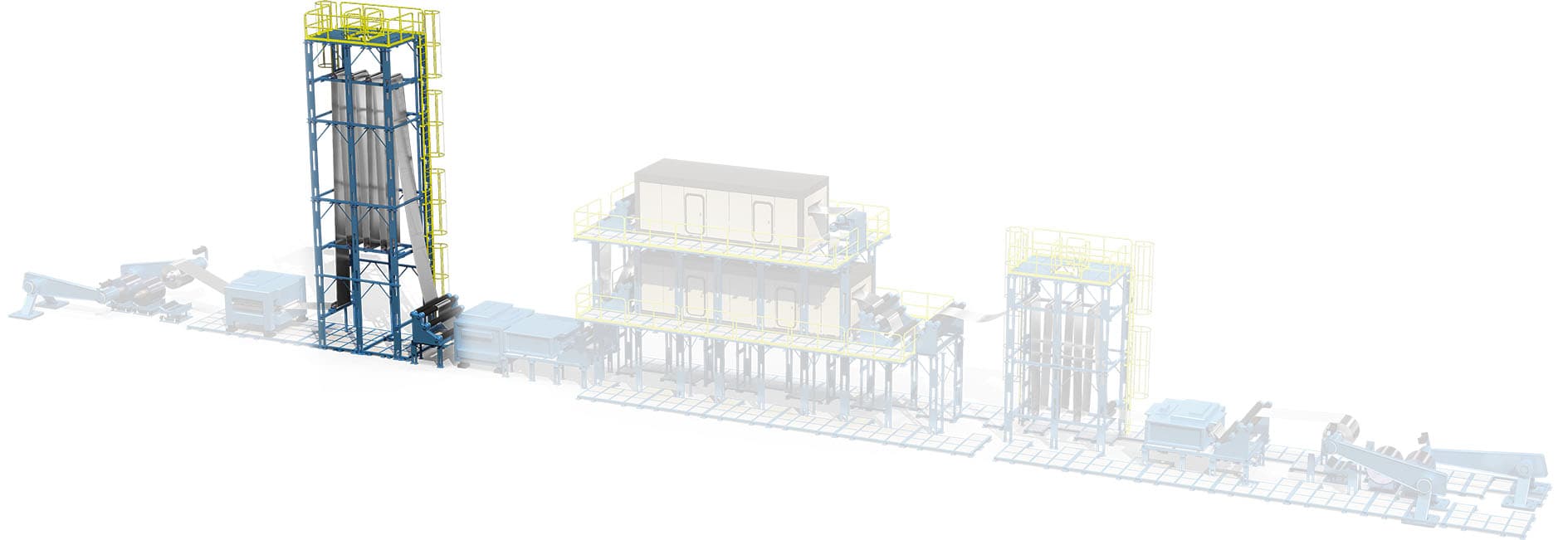

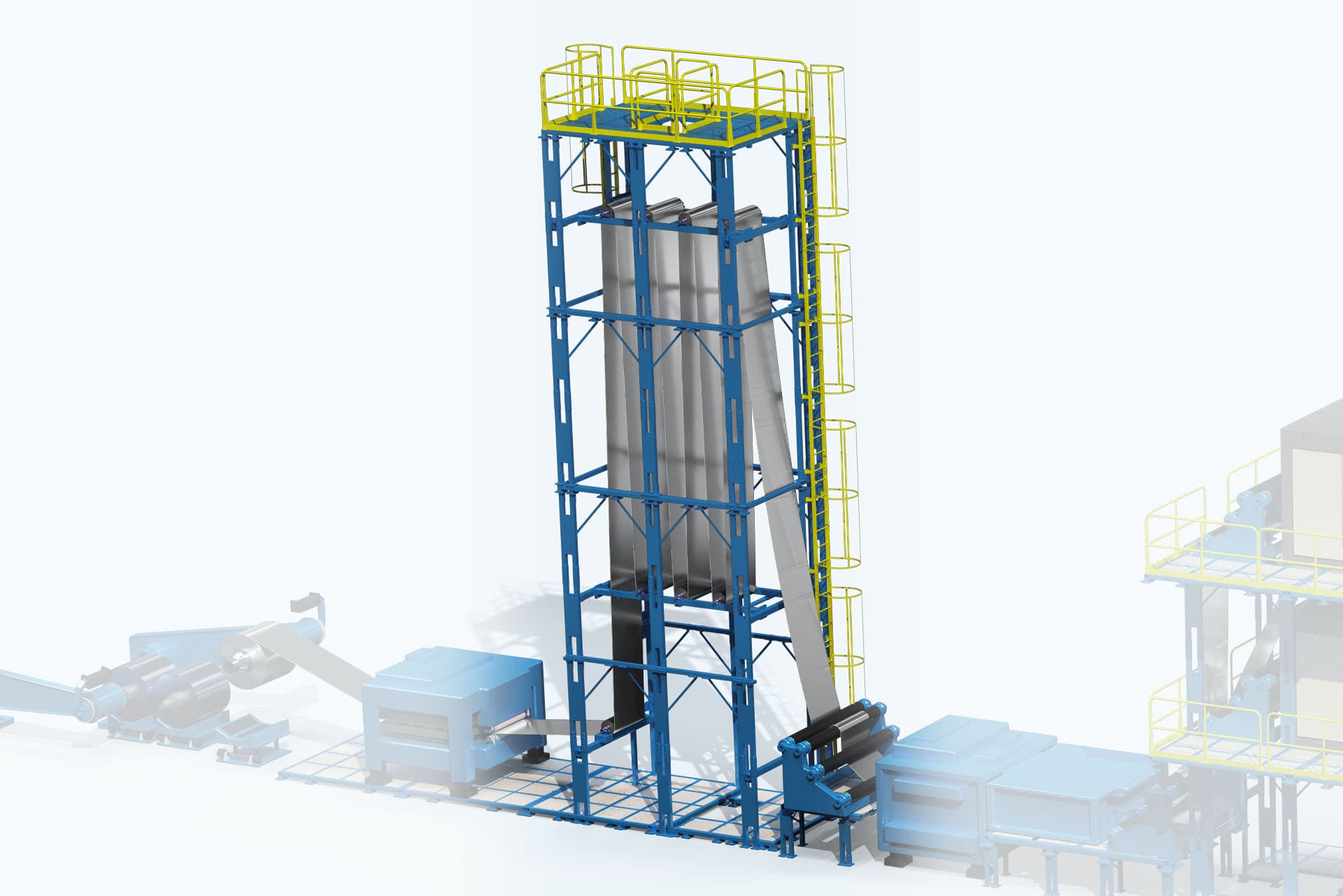

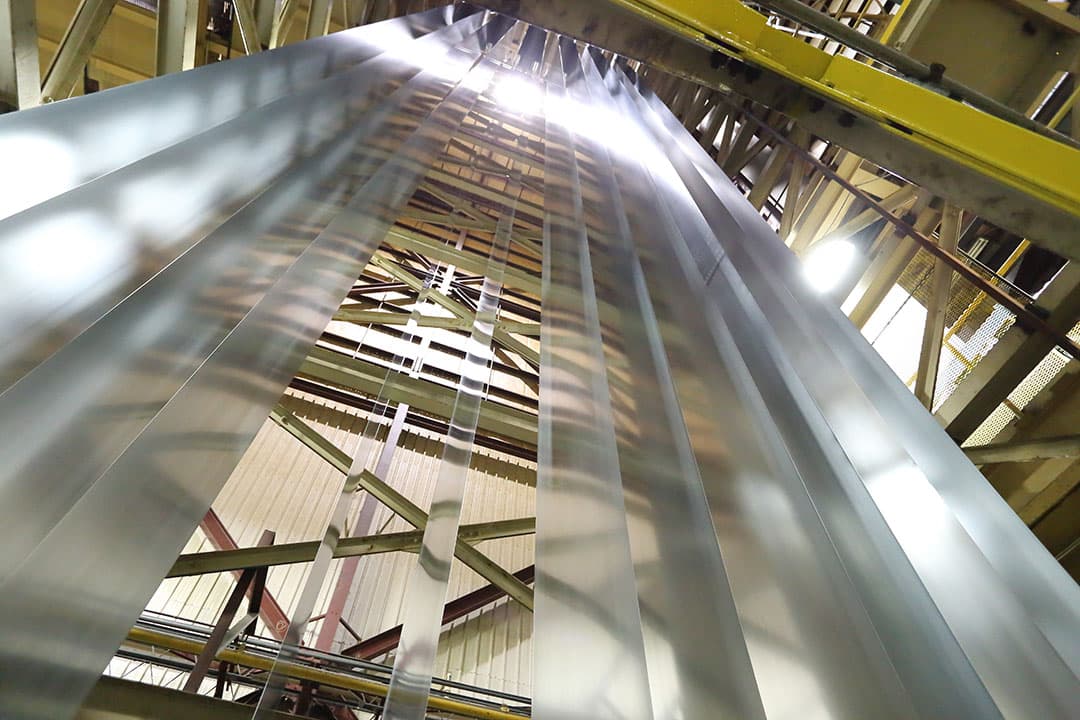

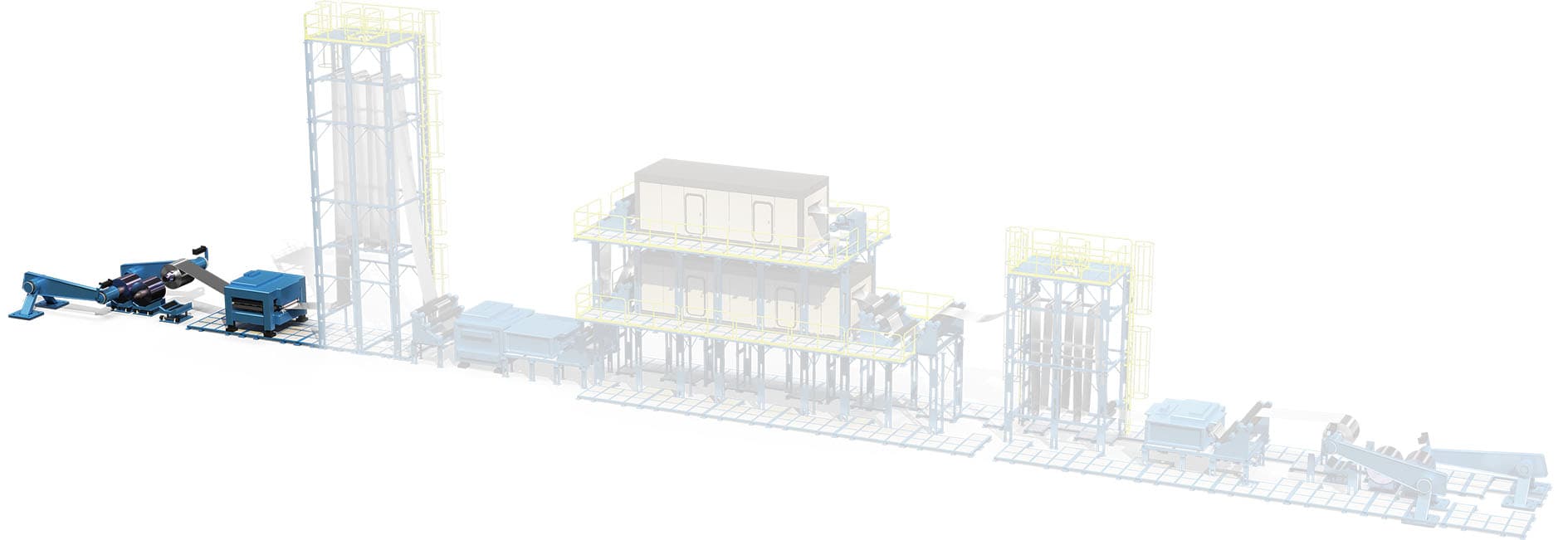

Coil Coating Process

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication