Cleaning & Pretreating

Cleaning & Pretreating

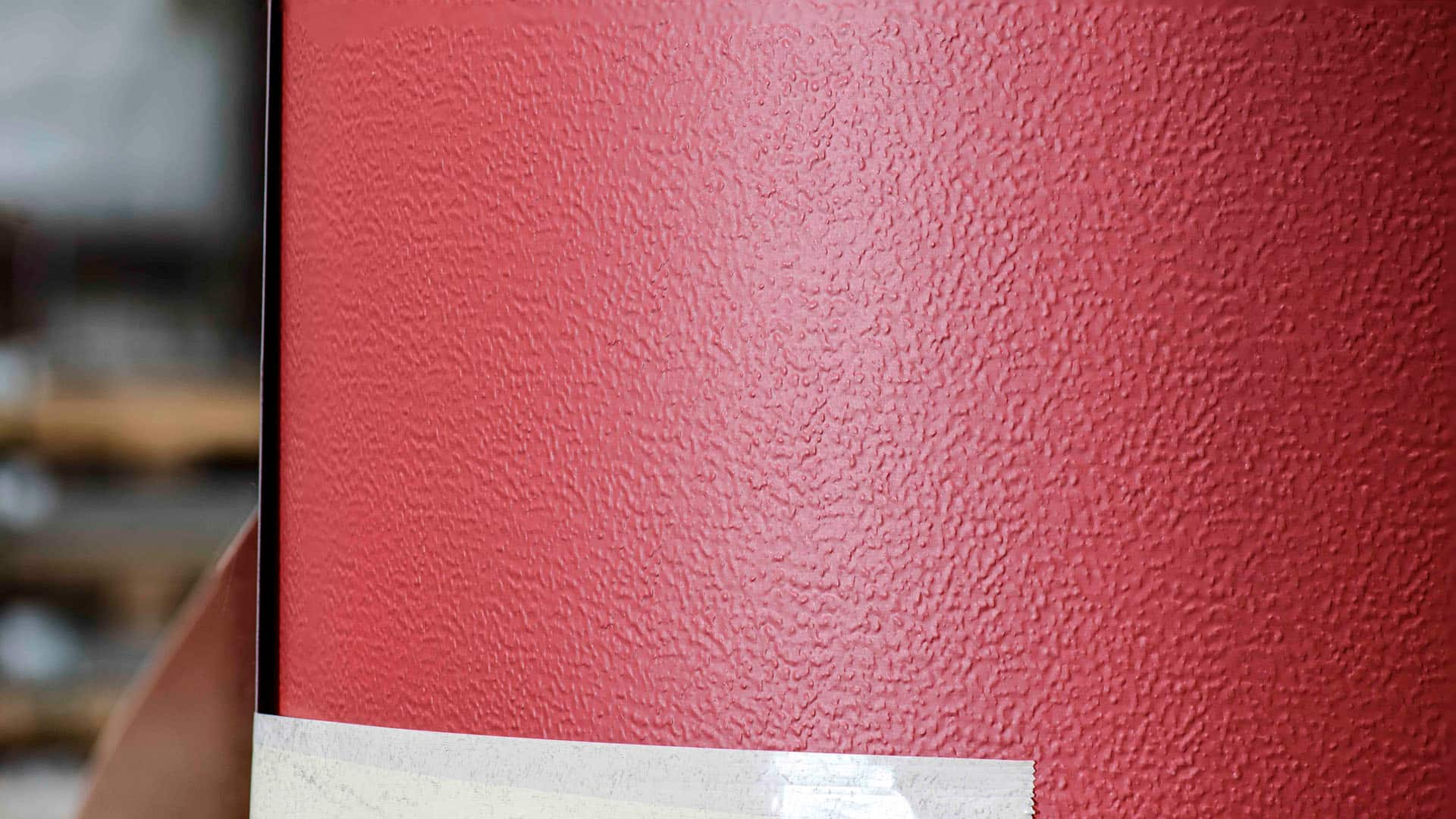

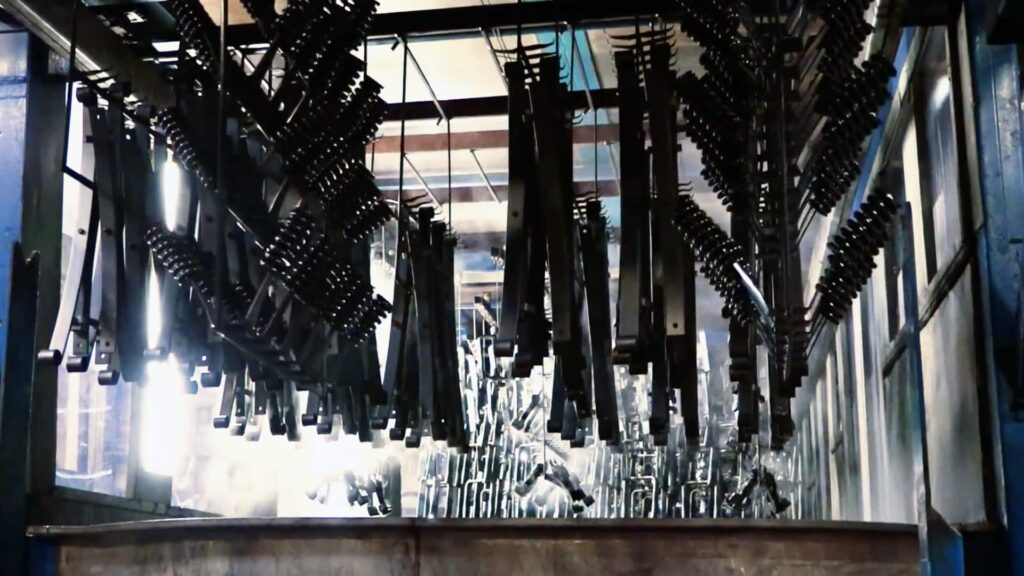

Achieve optimal results for superior end products

AZZ Precoat Metals guarantees premium quality, durability, and performance for coated products with our thorough cleaning and pretreatment expertise. We eliminate dirt, debris, oils, and contaminants from the metal surface, establishing a smooth and uniform substrate that ensures a superior bond between the metal and coating. Our precise pretreatment, utilizing specialized chemicals, optimizes the surface for enhanced paint adhesion and corrosion resistance. This not only facilitates better formability but also enables the creation of complex shapes without compromising the integrity of the coating.

Contact Us

Follow Precoat MEtals

Coil Coating Solutions

PCM Dimensions

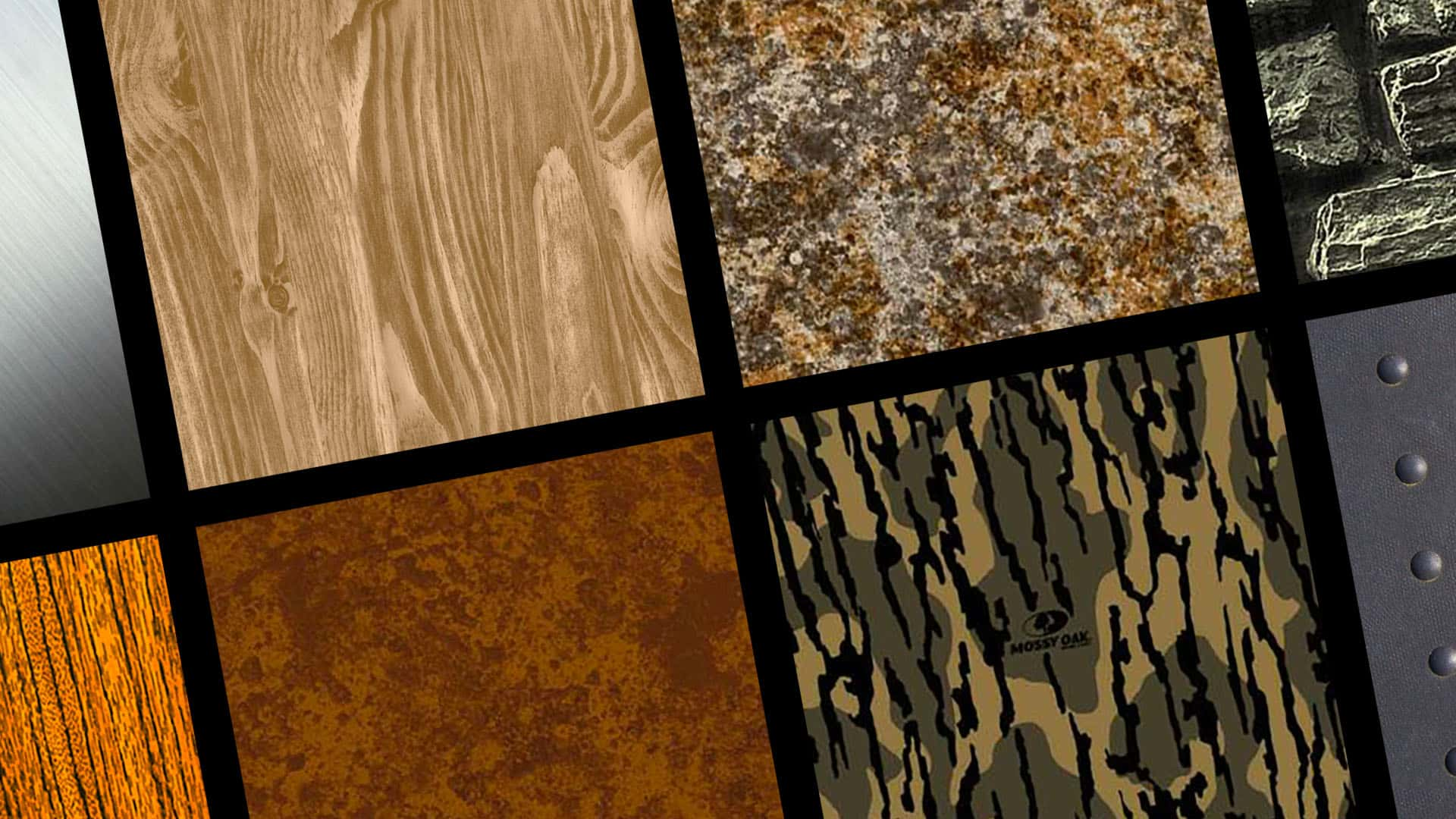

Aesthetics redefined

PCM Foundations

Building the future

PCM Mimics

Unearthed inspiration

PCM Xtremes

Performance unleashed

CoilZone Login

Visit CoilZone

Your secure, interactive, supply chain management system.

Locations

Learn About our Advantages

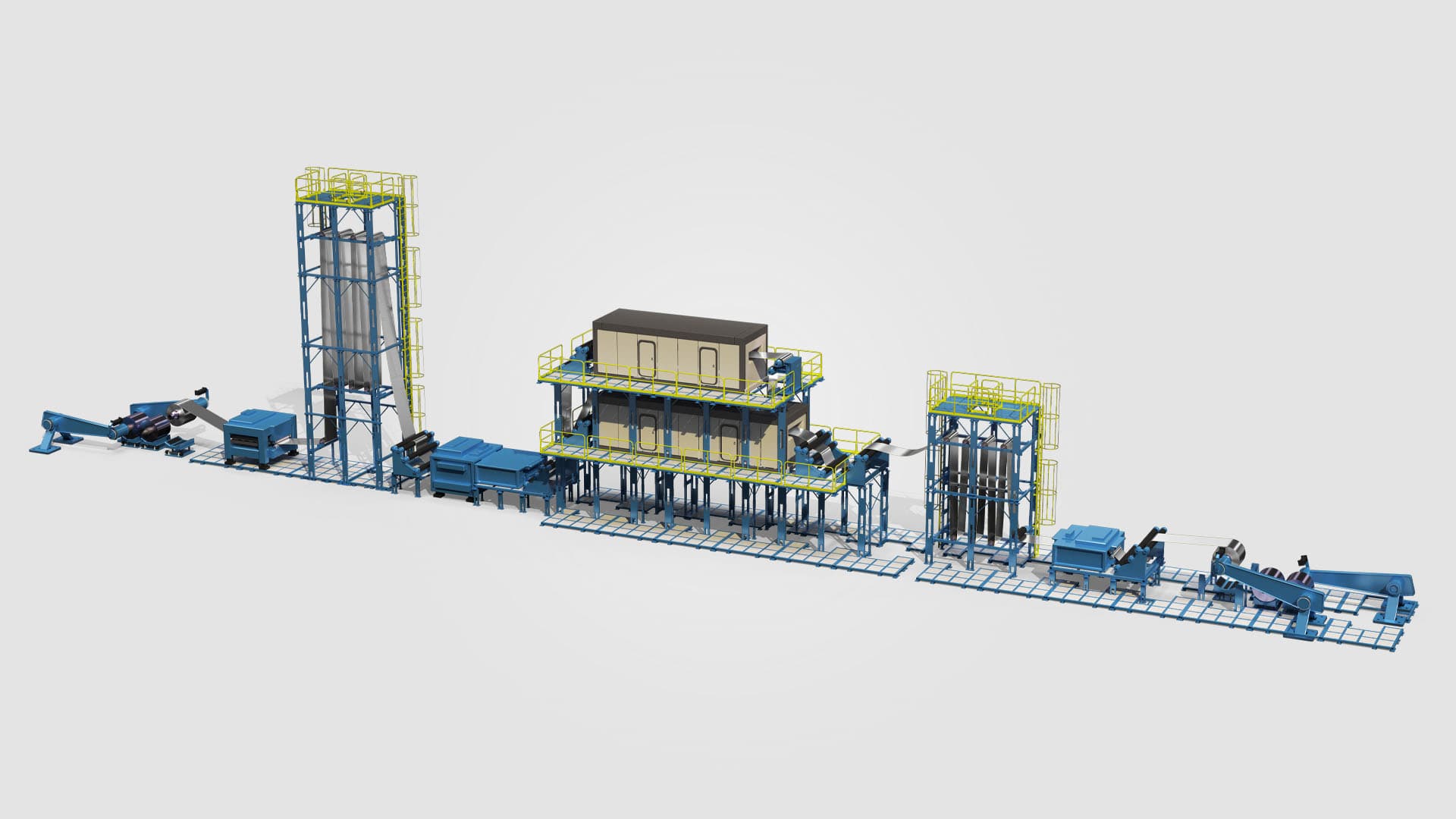

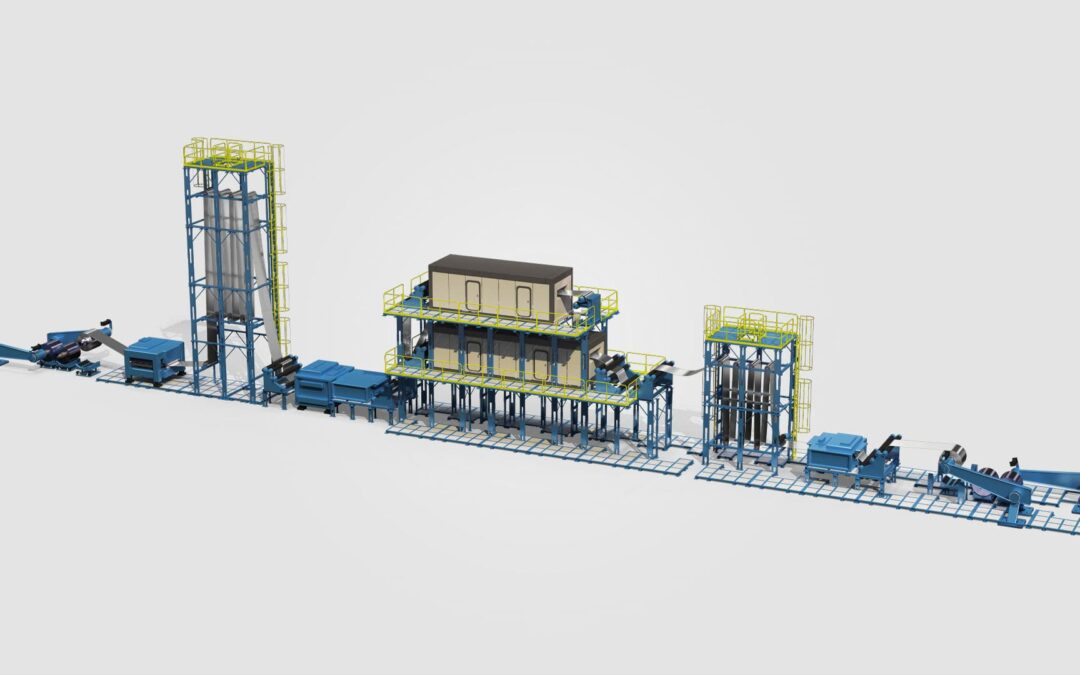

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication

Why Choose Coil Coating

Streamline processes, reduce costs, enhance product quality, and explore innovative coatings

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Business & Consumer Products

Performance-oriented coatings and film laminates for diverse applications

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication