Sustainable, Unmatched Metal Coating and Precoat Metals Solutions

We are North America’s leading independent provider of hot-dip galvanizing and coil coating services. At AZZ, we provide sustainable, unmatched metal coating solutions that enhance the longevity and appearance of buildings, products, and the infrastructure we depend on for everyday life.

Metal Coatings

As the continent’s largest hot-dip galvanizer of fabricated steel, AZZ is the company North America depends on to protect and improve the integrity of critical infrastructure while continuously working to reduce our carbon footprint

Precoat Metals

For over 60 years, AZZ Precoat Metals has been a leading provider of coil-coated metal solutions, delivering exceptional end-use appearance and performance attributes across various markets and thousands of applications worldwide

Investor Relations

We measure success by the value we create and take great pride in the roles we play to ensure our continued growth Investor RelationsFinancial InformationFeatured Stories

Enhancing Structural Integrity of Architecture with Galvanized Steel

Paul Doherty, President and CEO of The Digit Group, comments on how the integration of galvanized steel enhances the structural integrity and sustainability of architectural designs.

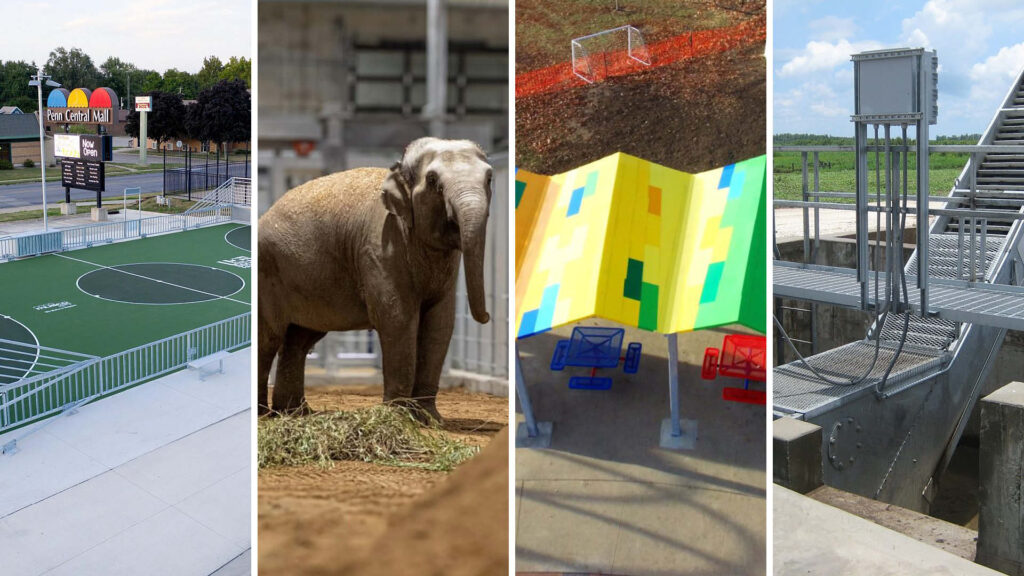

AZZ Metal Coatings Wins Four Excellence Awards at the 2024 American Galvanizers Association Conference

The annual Excellence in Hot-Dip Galvanizing Awards recognizes the special skill and efforts of galvanizers as they complete projects that will remain durable, beautiful, and maintenance-free for generations to come.

AZZ Metal Coatings is Proud to Serve Western Canada

Rugged and often remote, the Western Provinces are no place for an inexperienced galvanizer. With many project challenges unique to our region, a dependable and local coatings partner is vitally important. Our proven background includes a long history and a solid track record of delivering quality coatings within Western Canada.

Project Spotlight: Navajo Lake Marina Expansion (AZZ Galvanizing – Chelsea)

Navajo Lake State Park, just a short 40 miles east of Farmington, New Mexico, is the ultimate playground for adventurers. With 150 miles of shoreline, New Mexico’s second largest lake is the perfect getaway for boating, sailing and fishing enthusiasts.

Facility Locator

Find strategically located Metal Coatings and Precoat Metals facilities near you.