Spin Galvanizing

Cost-effective corrosion protection for small to mid-sized steel components

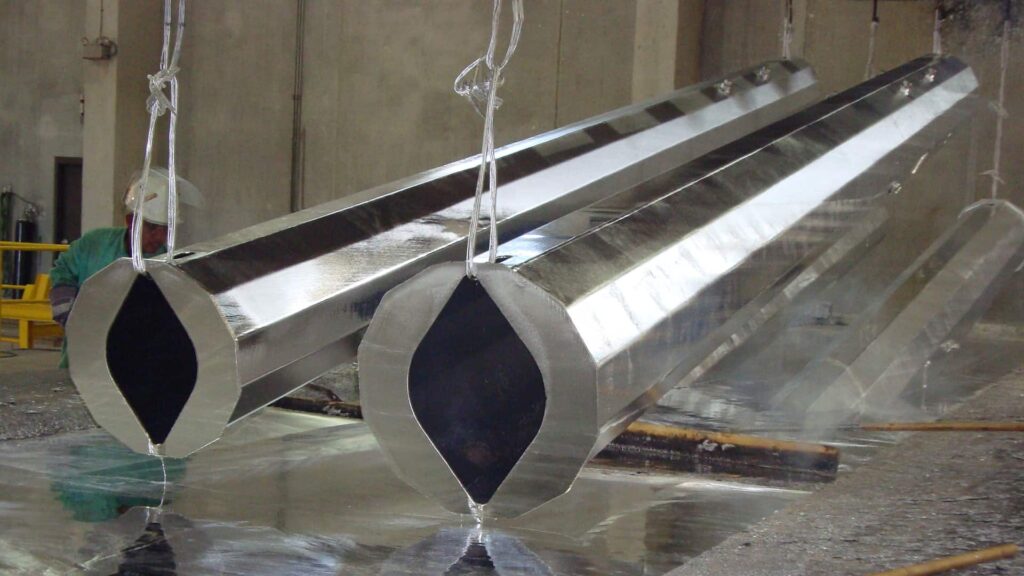

Spin galvanizing is a hot-dip process that utilizes a centrifuge anchored to a galvanizing kettle (or a spinner located above it) for immersing small to medium scale components in molten zinc. A tightly bonded alloy coating forms on the steel, providing long-term, durable protection from the devastating effects of corrosion, while the centrifuge or spinner removes excess molten zinc to ensure coating uniformity, quality fit, and precise functionality.

The spin galvanizing process, combined with AZZ’s automated conveyor lines, are used for a wide range of small to medium-sized components including all thread rods, nut blanks, guardrail bolts, anchor bolts, washers, turnbuckles, and wheels. The process provides high-performance corrosion protection and a consistent uniform coating.

Trusted Quality from AZZ

Smaller components can play a large role in maintaining a structure’s integrity and long-term performance. We have perfected the spin/centrifuge process resulting in galvanizing excellence for small parts, fasteners, nails, staples, and structural pieces. Our tightly controlled processes can ensure a quality nut fit on threads as small as 1/4″-20. AZZ is North America’s leading provider of hot-dip galvanizing with more than four decades of experience and an expansive network of more than forty galvanizing locations. Our spin operations are in adherence with standard specifications ASTM A153 and ASTM F2329, and ISO 9001 and 14001.

Big News for Small Parts

AZZ is pleased to bring state-of-the-art spin capabilities to our AZZ Galvanizing-Houston facility. We are operational and equipped to serve a broad range of customers across Texas and Louisiana. For added convenience, transportation is available and we’re happy to offer custom freight to and from D/FW, San Antonio, Austin, Waco, Baton Rouge and the Beaumont Golden Triangle.

Related Featured Story

Big news for small components: Introducing Texas’ newest and best option for small to medium sized parts.

We're pleased to bring state-of-the-art spin galvanizing capabilities to our AZZ Galvanizing-Houston facility.

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Hot-Dip Galvanizing Process

A tested and proven galvanizing process ideal for modern applications