Printing

Printing

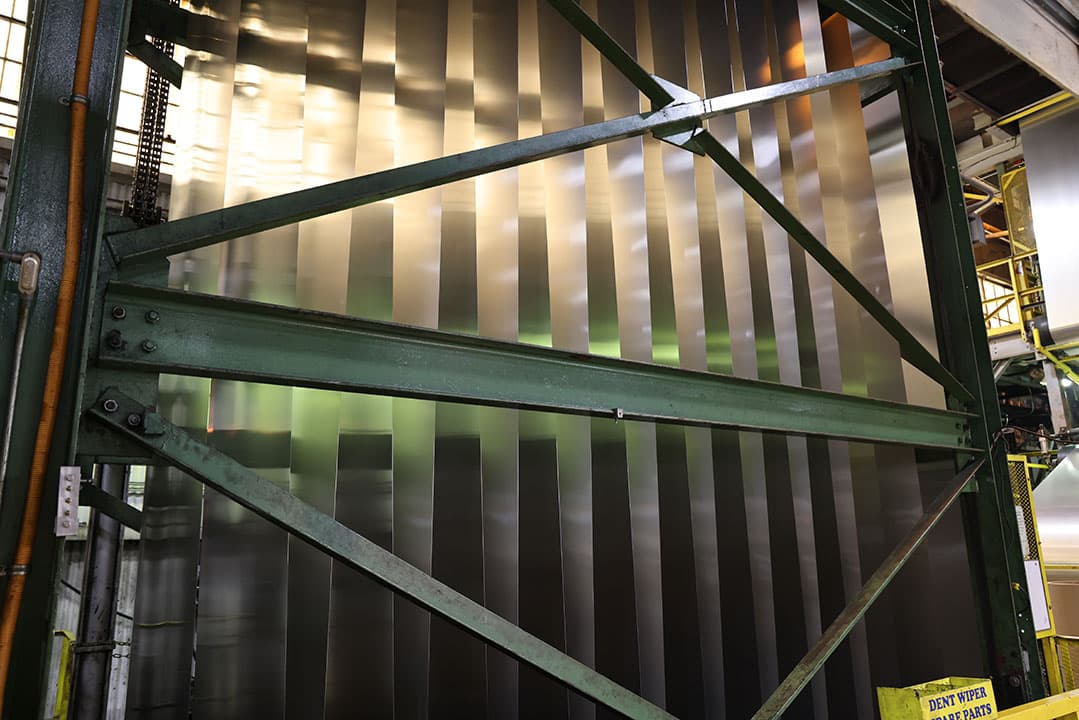

Cutting-edge printing processes redefine industry standards

AZZ Precoat Metals offers a series of innovative coating solutions that involve printing designs or patterns on metal coils before they undergo further fabrication. Our expertise in coatings allows for efficient and precise applications on metal surfaces, enhancing the appearance and aesthetics of the final products.

Contact Us

Downloads

Follow Precoat MEtals

Coil Coating Solutions

PCM Dimensions

Aesthetics redefined

PCM Foundations

Building the future

PCM Mimics

Unearthed inspiration

PCM Xtremes

Performance unleashed

CoilZone Login

Visit CoilZone

Your secure, interactive, supply chain management system.

Locations

Capabilities by Precoat Metals location

| Cut-to-Length | Embossing | Laminating | Printing | Shape Correction | Slitting | |

|---|---|---|---|---|---|---|

| Baltimore | • | Directional Stucco | • | • | ||

| Birmingham | Non-Directional Stucco; Seville | • | • | |||

| Columbia | • | Directional Stucco; Seville; Rough Sewn Cedar | • | • | ||

| Greenfield | Directional & Non-Directional Stucco; Seville 101; Rough Sewn Cedar | • | • | |||

| Hawesville | Seville 101 | • | • | |||

| Houston | ||||||

| Jackson | • | Directional Stucco | • | • | • | |

| Kingsbury | • | • | • | |||

| MMC | • | • | ||||

| Northgate | • | |||||

| Portage | • | • | ||||

| St. Louis | • | • | • | |||

| Weirton | • | • |

Learn About our Advantages

No Results Found

The posts you requested could not be found. Try changing your module settings or create some new posts.

Accreditations

AZZ is a proud member of the American Galvanizers Association and many other industry organizations

Business & Consumer Products

Performance-oriented coatings and film laminates for diverse applications

Cleaning & Pretreating

Ensures the quality, durability, and performance of coated products

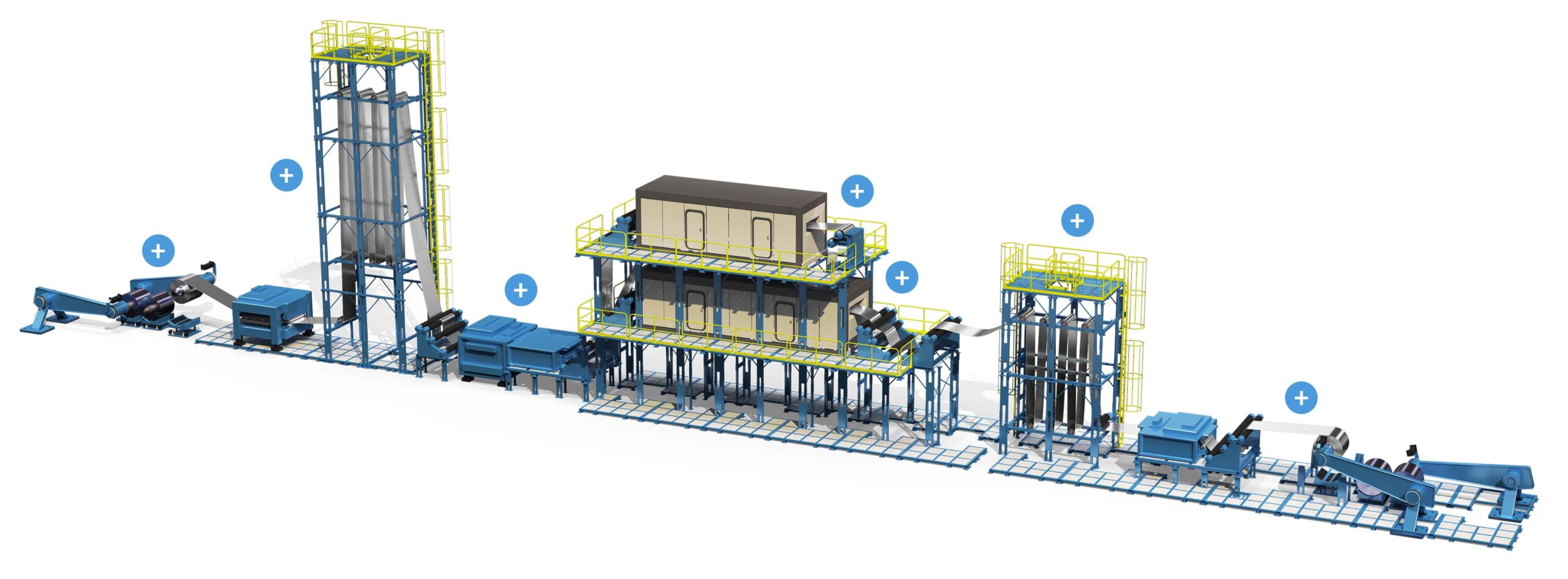

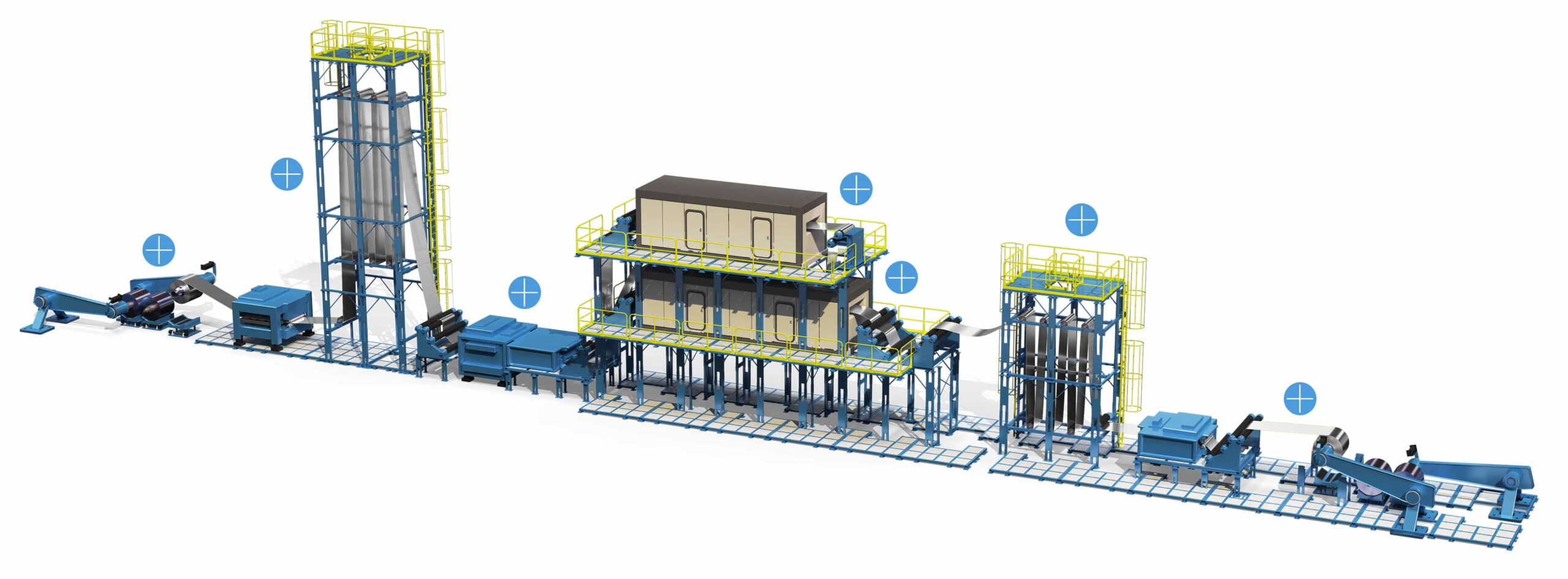

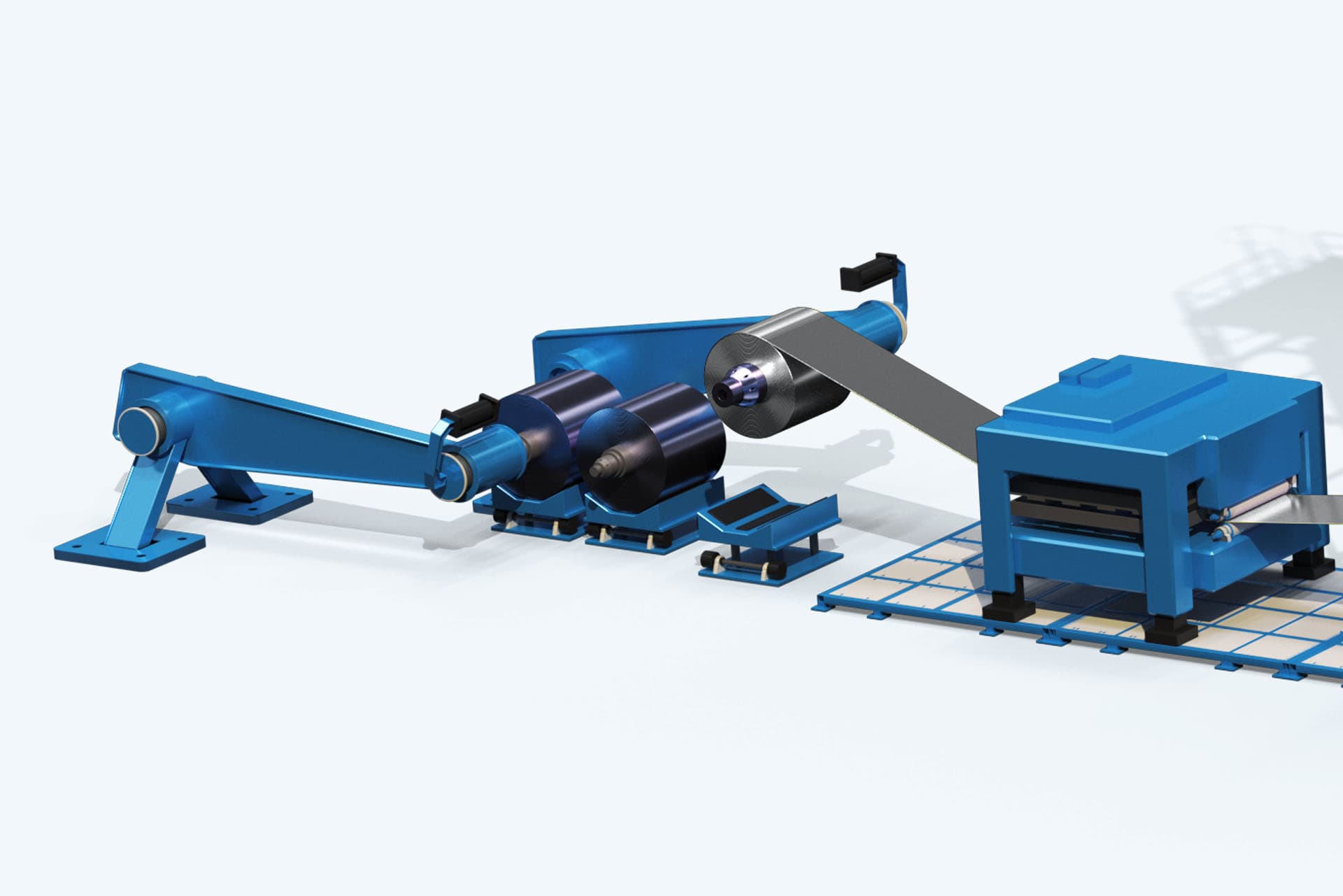

Coil Coating Process

Explore the continuous, automation of our coil coating process ensuring uniform, high-quality metal coated finishes before fabrication