More than Natural. It’s Essential.

Zinc is a naturally occurring element that plays an extremely important role in both our environment and health. All organisms depend on the presence of zinc and due to its general availability and unique characteristics, it has become an essential component for many metabolic processes that sustain life. In all forms of life, zinc works at the cellular level by enhancing protein and enzyme function and serves many functions related to gene maintenance, the immune system, vision, and organ and tissue growth (International Zinc Association 2017). Simply stated, zinc is essential.

Zinc and Health

Unfortunately, more than two billion people across the globe don’t receive enough zinc in their daily diets. As a major health issue in numerous developing countries, zinc deficiency poses a serious risk, especially to the young. A lack of the nutrient hampers the immune system, leaving those affected prone to growth retardation, infections, hair loss and skin rashes. Tragically, it has been estimated that over 1.2 million people annually die indirectly from zinc deficiency.

In 2006, the Copenhagen Consensus, a group of internationally acclaimed economists, including five Nobel Laureates, concluded that combating the world’s malnutrition problem through the provision of vitamin A and zinc was rated the highest among the various cost-effective solutions to the worlds pressing problems (IZA 2017)

Zinc and World Agriculture

Although zinc occurs naturally within the environment, many regions lack the element in sufficient concentrations to support healthy crop quality and yields. In fact, half of the world’s cereal crops are grown in zinc-deficient soils. The result is stunted growth, diseased leaves, and anemic harvests in geographies whose populations can least afford it. Compounding the problem—crops that are harvested will ultimately contain low amounts of zinc—thereby contributing to zinc deficiency in those that consume them.

As the global population continues to climb (estimates top 9 billion people by 2050), the agricultural output must expand by 70 percent to meet the world’s nutritional needs. To achieve this level of production, the focus has turned to the potential adoption of zinc fertilizers to help boost crop yields. In China, trials on rice crops have been impressive, demonstrating 20 percent increase in yields and a 40 percent in the nutritional content.

Zinc and Energy

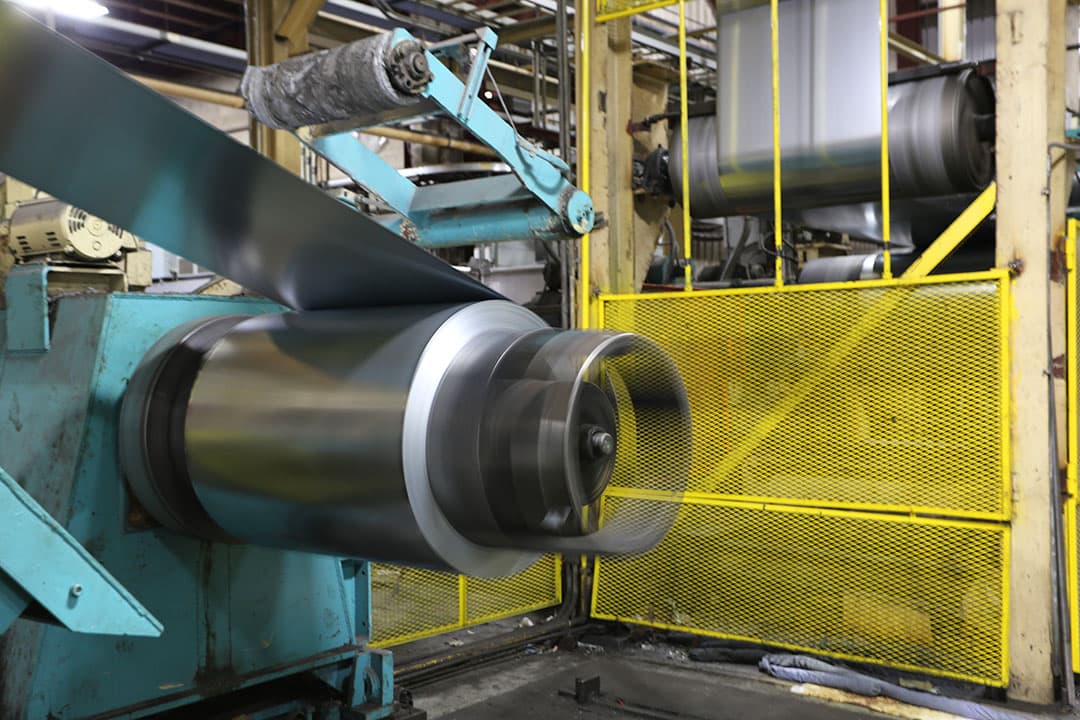

One of zinc’s greatest properties is its ability to protect steel from corrosion. For decades, zinc has played an integral role in safeguarding the core of our nation’s electrical infrastructure—from the largest transmission towers to the most critical distribution components. As a new era in clean and renewable fuels emerge, anti-corrosion zinc coatings such as hot-dip galvanizing and Metalizing thermal spray are now protecting assets such as wind turbines and solar arrays.

Zinc is helping renewable power become 24-hour power. Zinc-based energy storage systems have tremendous advantages including high specific energy, recyclability, safety, low cost, and zero emissions. As a result, zinc is used in the manufacture of a variety of battery chemistries, both primary and rechargeable, consumer, and industrial (IZA 2017).

Source: International Zinc Association, 2017