Company

Case Studies

Learn how AZZ has helped our customers

Filter By Category

Forest Park Beach Ramp

The City of Lake Forest identified the necessity for a safer, more accessible pathway connecting a 600 foot hilltop to the Lake Michigan waterfront.

Fountain of Light: 50 Years of the Fountain

In honor of the 50th anniversary of Fountain Hills’ iconic fountain, local artist Brian Schader was commissioned to create a new sculpture that would enrich the town’s public art collection.

Stadium Seating System

The Solara Stadium Seating system by Irwin Seating Company is a premium solution designed to meet the demands of high-traffic venues such as arenas, stadiums, and outdoor event spaces. Engineered for durability, functionality, and aesthetic appeal, Solara seating offers an ideal combination of strength and versatility.

Columbia Vehicles Payloader

When you live in the Midwest and someone asks you about running a project for Hawaii, it tends to gain interest very quickly. Wisconsin may be pretty distant from Hawaii in both miles and climate, but steel in each location has a common enemy. Salt from the ocean water mixed with air and heat can wreak just as much havoc on steel as the salt combined with snow and wind up north.

Lunmar Galvanized Boat Lifts

Since its establishment in 1993, Lunmar Boat Lifts has been a trusted provider of high-quality boat lift solutions for fresh, brackish, and saltwater environments. Its commitment to excellence is reflected in the choice of a galvanized finish for all lift components, offering unparalleled protection against corrosion and ensuring a longer service life.

Easy-to-Assemble DIY Bridges for Farmers and Landowners

For farm owners and landowners, gaining efficient access to every corner of their property is crucial for productivity. Streams, drainage ditches, or small ravines often disrupt access, making it challenging to move equipment, tend to livestock, or fully utilize the land.

Shred-Tech Mobile Shredding Trucks

The mobile shredding industry demands durability and longevity, particularly in the face of harsh road conditions and operational challenges unique to shredding trucks. Shred-Tech, a leader in mobile shredding solutions, and Allvan, a premier manufacturer of truck bodies, have partnered to pioneer the use of hot-dip galvanizing (HDG) in mobile shredding trucks.

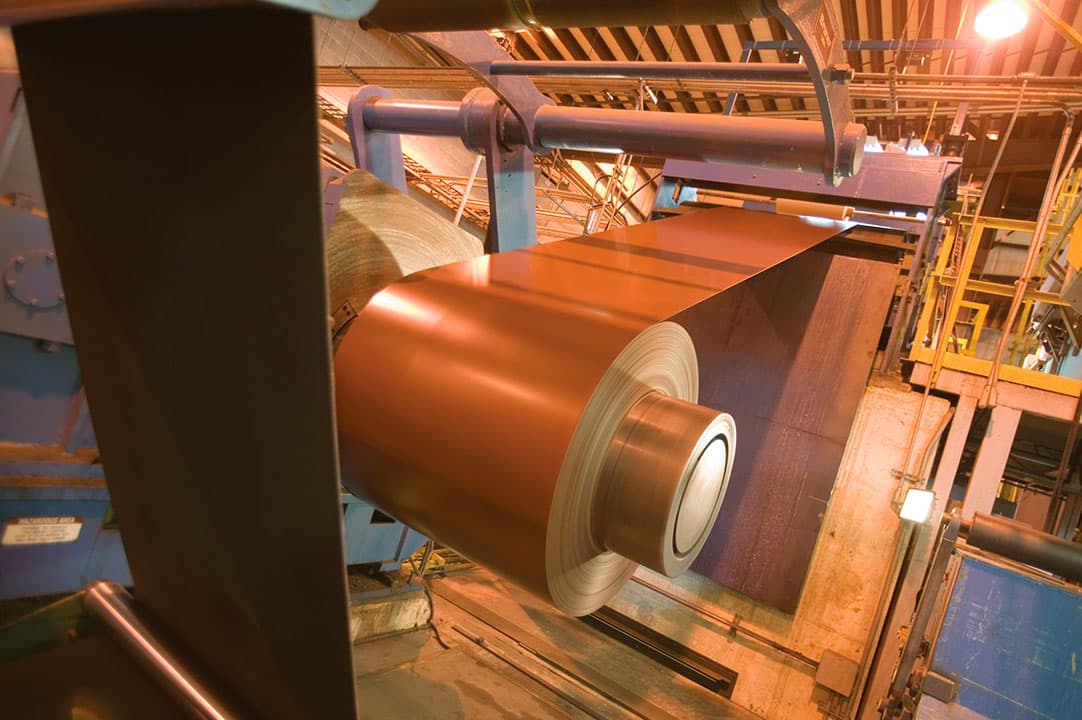

Buchanan Coal Mine

In the Appalachian Mountains of Virginia, coal mining has long been central to the culture and livelihood of the community. Over the past decade, many coal mines have closed due to green energy initiatives. However, one mine, the Buchanan Mine in Oakwood, Virginia, has remained open and thriving thanks to the type of coal it produces. Owned and operated by Coronado Coal Company, the mine specializes in metallurgical coal, or “met coal,” a crucial ingredient in producing coal for steel manufacturing.

Non-Redirective Safety Crash Cushions

In Canada, non-redirective crash cushions play a vital role in roadside safety, particularly on high-speed highways and urban roadways. These systems are installed to protect drivers from fixed hazards in situations where redirecting vehicles away from impact points is impractical, such as around toll plazas, bridge abutments, and exit ramps.

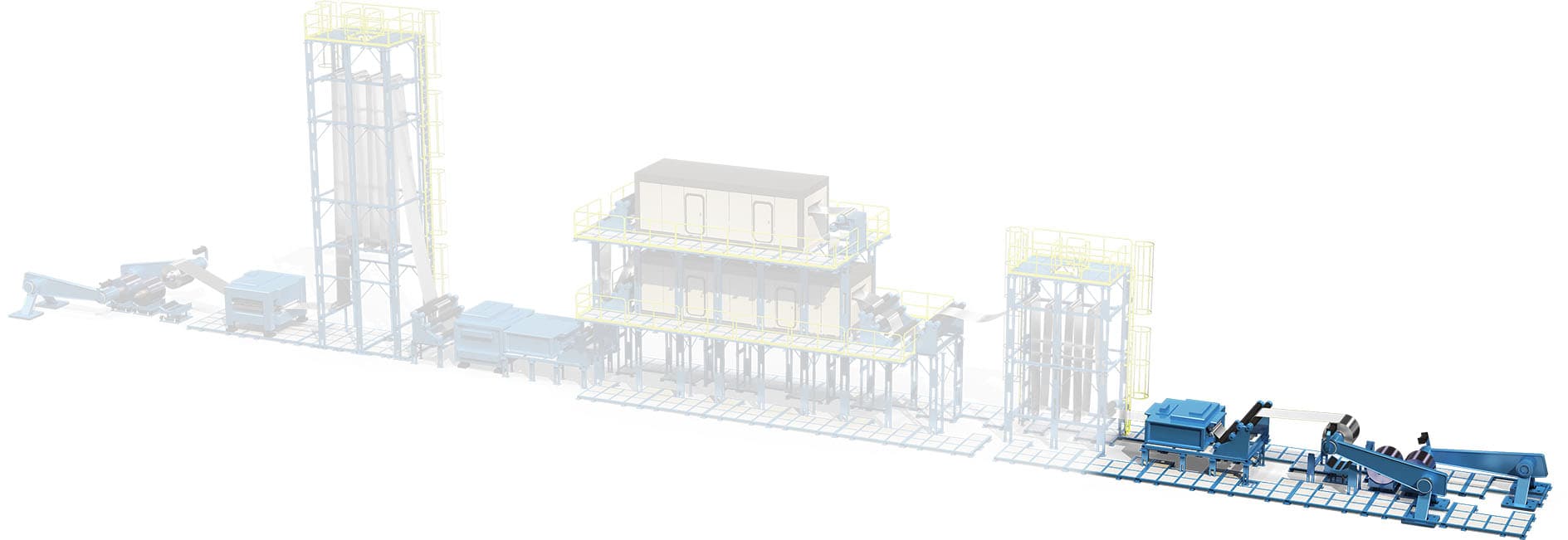

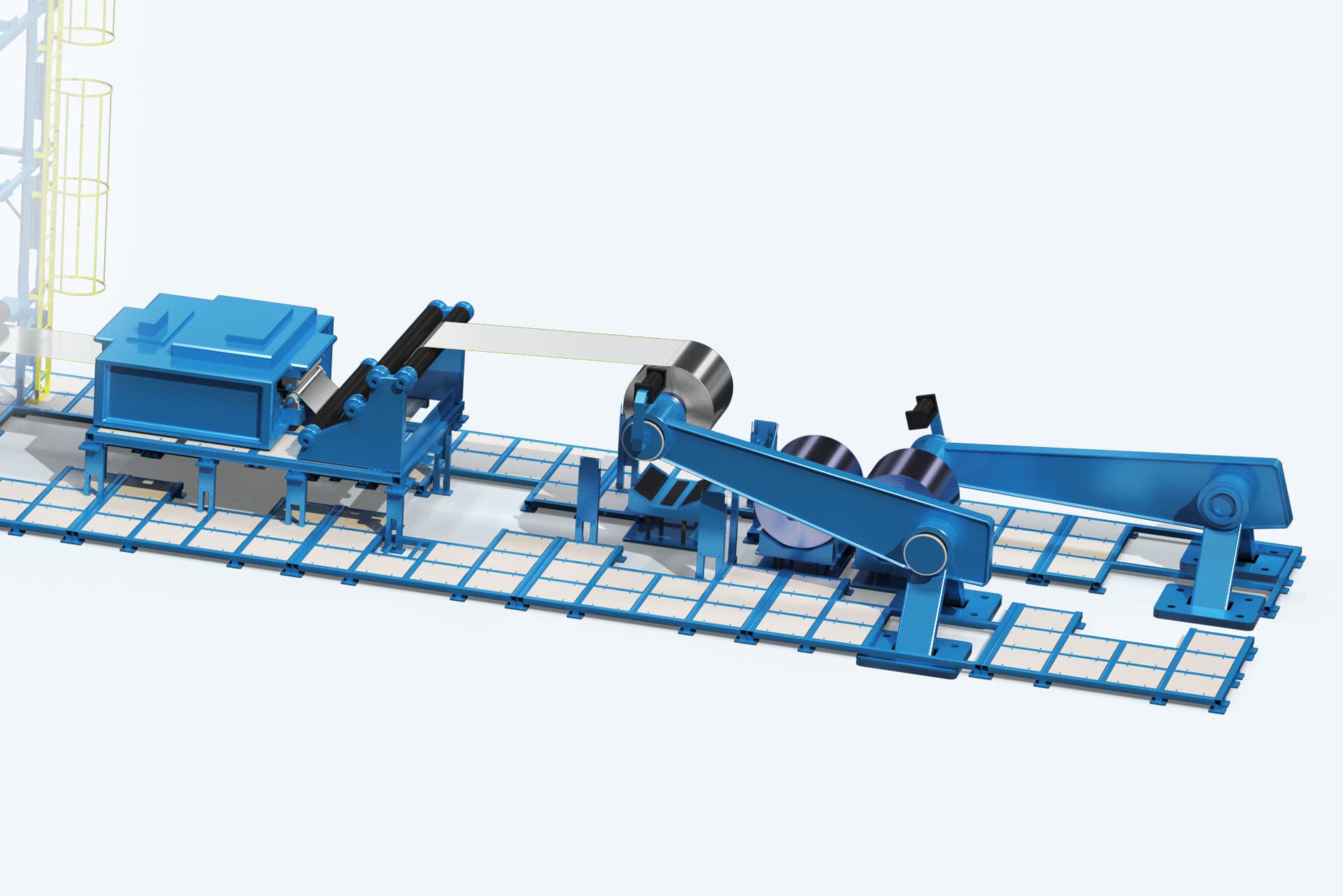

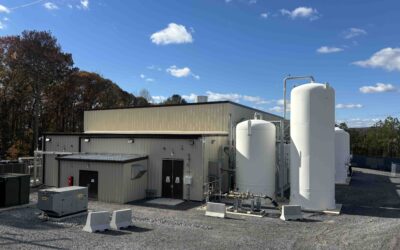

Bradley County RNG Facility

Renewable Natural Gas (RNG) offers a transformative opportunity to turn waste into wealth by converting organic matter such as landfill solids into energy and is uniquely positioned to power local economies. The U.S. alone produces over 250 million tons of waste each year, 140 million of which goes to landfills.

Gregg McNair Standardbred Training Facility Renovation

Gregg McNair Stable is a top-tier standardbred training facility known for its efficiency and success in the WEG circuit. Recently, the facility underwent a major renovation and the addition of a new barn, both of which incorporated Custom Finish Line galvanized horse stalls.

Heavy Duty Loading Ramps

Lesco Design & Manufacturing, a trusted leader in the manufacturing industry for over 60 years, has built its reputation on engineering solutions that withstand the test of time and use. With a primary focus on serving the automotive industry, Lesco is known for delivering quality components that meet the sector’s stringent demands.

Flexstep Containment Wall Catwalk Crossover

Access to containment walls in industrial environments is often fraught with challenges. These walls are frequently tall or situated in hard-to-reach areas, requiring specialized equipment for safe access. Uneven terrain, sloped surfaces, or obstructions further complicate the placement and stability of access structures.

Combat Training Communication Trailer

Founded in 1977, Rolltechs Specialty Vehicles is a Texas-based leader in the design and manufacture of specialty vehicles. With decades of experience, the company delivers a diverse range of state-of-the-art mobile solutions, including command vehicles, broadcast vehicles, truck bodies, food trucks, and satellite vehicles. Known for innovative designs and rugged construction, these products serve clients worldwide, offering reliability and cost-effectiveness in even the most demanding environments.

Mini Pitch Systems

Throughout the United States, many areas have a scarcity of parks and green spaces, which are essential for recreational activities such as soccer, basketball, and other fitness pursuits. Even when parks or facilities are available, they may not be well-maintained or past their useful service life, which can discourage people from using them. Worse yet, broken equipment, unsafe conditions and a lack of upkeep can contribute to significant safety issues.

Cincinnati Zoo Elephant Trek (AGA Excellence Awards Winner)

The Cincinnati Zoo’s Elephant Trek is a 5-acre habitat that will be home to endangered Asian Elephants. The habitat is complete with a barn area which consists of primarily hot-dip galvanized steel structures to aid in the care and shelter of the endangered Asian Elephants. This galvanized Elephant Trek exhibit provides a durable and environmentally friendly habitat that will be a catalyst in joining both visitors and elephants in a huge way!

Agpro Waste Management (AGA Excellence Awards Winner)

Agpro Waste Management specializes in providing sustainable waste management solutions for agricultural industries. With the increasing concern about environmental degradation and the need for sustainable practices, Agpro has emerged as a leader in this growing market.

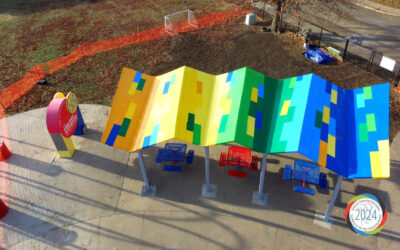

Ryan Gray Playground Pavilion (AGA Excellence Awards Winner)

The Ryan Gray Playground for All Children was the first ADA accessible playground in the State of Kansas when it opened in 1993. The playground was built in memory of Ryan Gray – a disabled student at Hillcrest Elementary, where the playground is located.

Long Live The Queen!

The origin of today’s ski lifts may seem a little surprising. In the early 1930’s, the Union Pacific (UP) Railroad operating through some of the country’s most mountainous territory, decided to develop and operate a world-class winter sports resort.

Can You Hear Me Now? How ConcealFab and hot-dip galvanizing are shaping the 5G Landscape

First generation mobile networks were introduced in Japan in 1979 and rolled out in other countries including the United States in 1980. Reliant on analog radio systems, users could only make phone calls, they could not send or receive messages.

Rescue Training Towers

Every day, emergency incidents happen around the United States, and responders must be ready. Rescue training towers significantly enhance the safety of workers in petrochemical and industrial plants by providing a controlled environment for realistic emergency response training.

Remote Surveillance Systems

LiveView Technologies (LVT) offers advanced surveillance systems designed for flexible and remote monitoring. These systems feature high-definition cameras, real-time video streaming, and advanced analytics, all integrated into portable, solar-powered units. Ideal for various applications, including construction sites, events, and public safety, LVT’s surveillance systems provide reliable, on-demand security solutions that can be quickly deployed and easily managed through a user-friendly platform.

Genesis Trailers

Welcome to the heart of marine trailer innovation and craftsmanship—Genesis Trailers in Holland, Michigan. Nestled in the vibrant maritime community of Holland, this dynamic company stands as a statement of excellence, pushing the boundaries of marine trailer design and manufacturing.

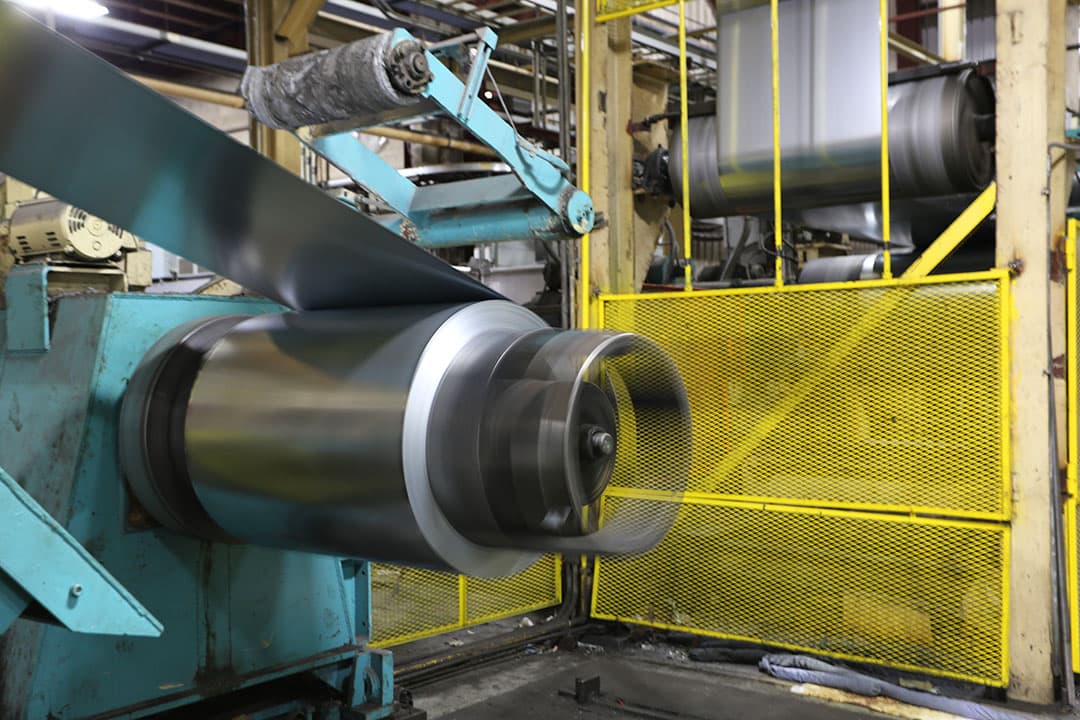

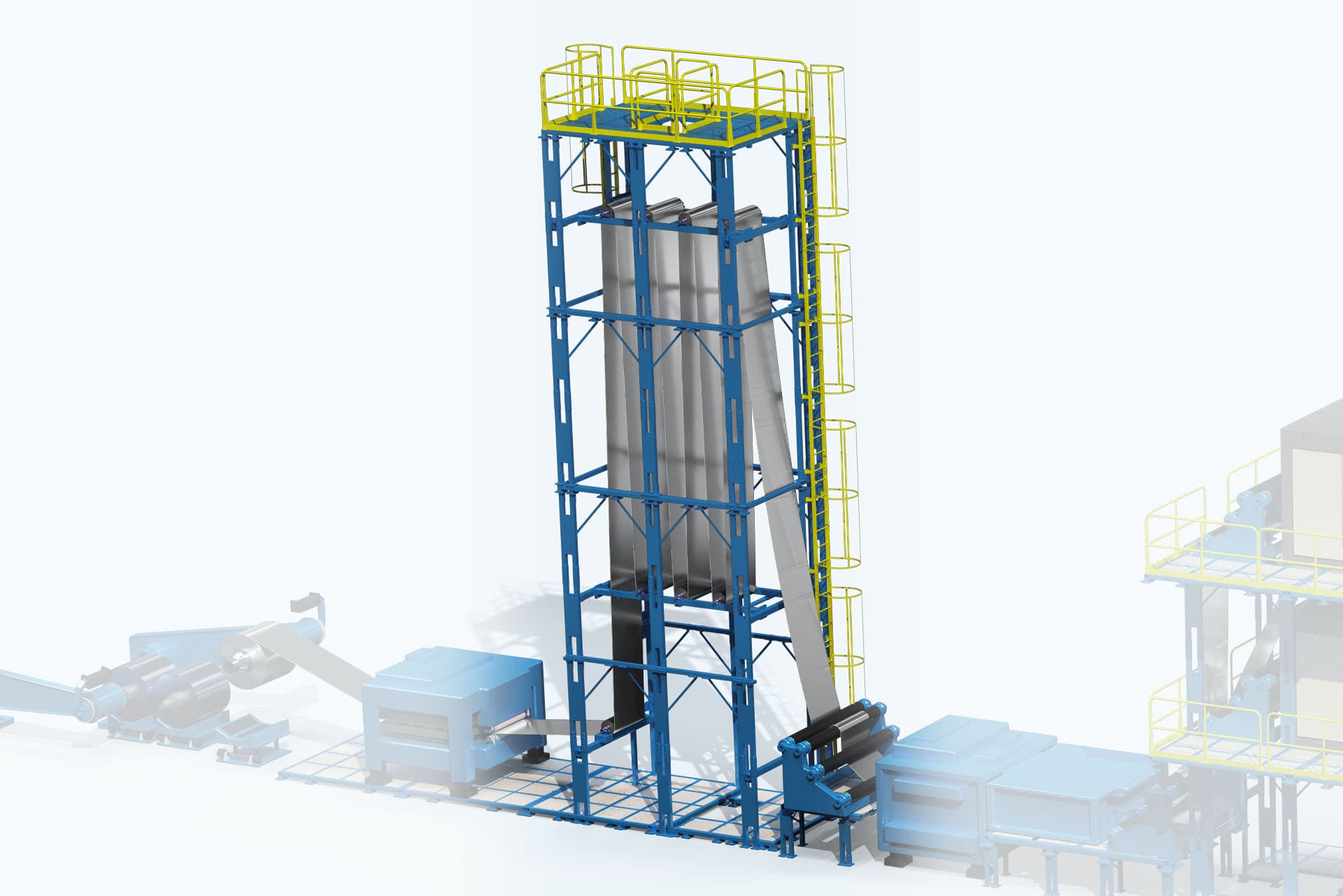

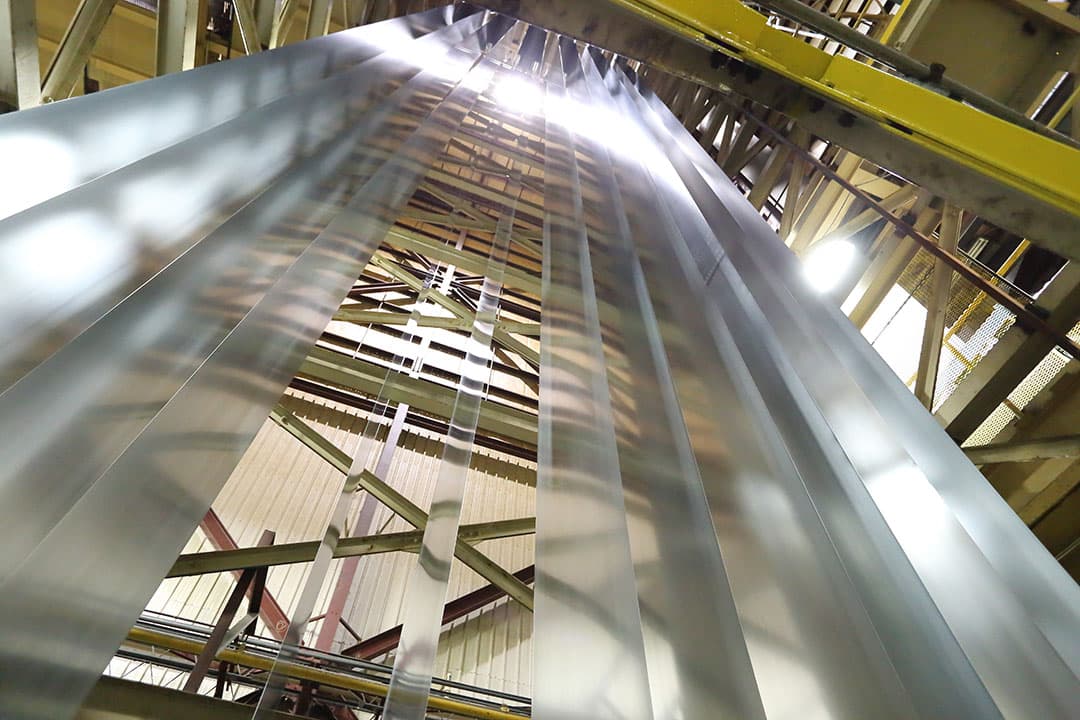

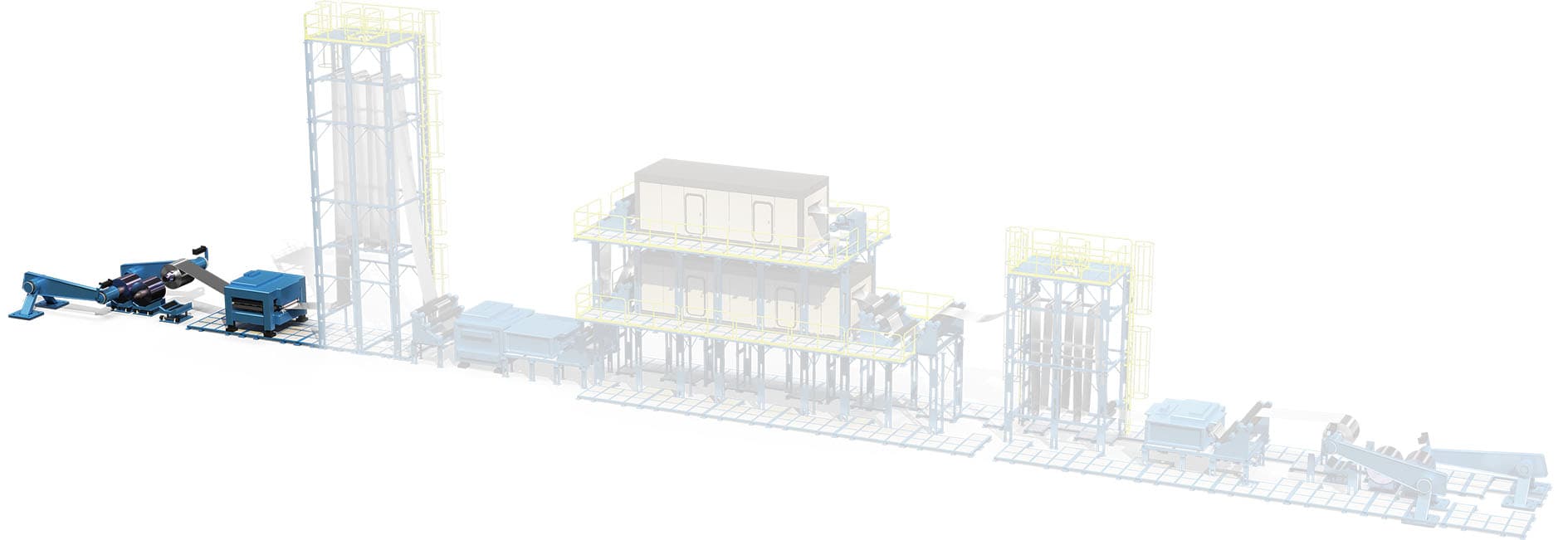

Henderson County Mine Conveyor

Coal has been a major part of Kentucky’s economy and history for over two centuries. In 1750, Dr. Thomas Walker discovered coal in what would later become Kentucky, and the first commercial coal mine was opened in 1790 (2 years before becoming a state).