Featured Stories

Filter By Category

American Galvanizers Association Excellence Awards: Topeka Children’s Discovery Center (Civic Contribution Category)

“AZZ Galvanizing – Kansas City” provided the perfect solution to safeguard an innovative canopy structure at a nonprofit children’s museum in Topeka, Kansas.

American Galvanizers Association Excellence Awards: Schomp Automotive Group – “Hail No” (Original Equipment Manufacturing Category)

“AZZ Galvanizing – Denver” played a vital role in protecting the columns that support an innovative anti-hail netting system in use on Colorado’s Front Range.

American Galvanizers Association Excellence Awards: Protective Stadium – UAB Blazers (Recreation & Entertainment Category)

“AZZ Galvanizing – Crowley” provided corrosion protection for the centerpiece of Birmingham’s entertainment district – and earned a 2022 AGA Excellence Award in the process.

The Importance of AS9100 and NADCAP Certification

Imagine flying miles above the ground and traveling at speeds of upwards of 500 miles per hour. Now imagine the parts that have to sustain these types of conditions, from extreme heat to extreme cold to the harshest storms. For these exact reasons, there are standards in place to ensure these parts are suited to maintain integrity under these rigorous conditions.

AZZ Metal Coatings Set to Exhibit at FABTECH 2021

North America’s largest metal forming, fabricating, welding and finishing event heads to Chicago and McCormick Place, September 13-16, 2021.

5 Interesting Facts about Anodizing

The anodizing process provides effective corrosion protection – and maintains a colorful history.

Welding After Hot-Dip Galvanizing

All commonly practiced welding and cutting techniques can be used on galvanized steel (see American Welding Society’s [AWS] specification D – 19.0, Welding Zinc-Coated Steel). Welding on galvanized steel is usually necessary if the final structure is too large to be dipped in a galvanizing bath or for structures that must be welded in the field.

What is the Best Material for Utility Poles?

They’re a familiar sight – they line city blocks and country roads, carrying powerlines and serving utilities. Utility poles come in a variety of materials and designs, but what material actually provides the best combination of performance, cost, and environmental impact reduction?

Big news for small components: Introducing Texas’ newest and best option for small to medium sized parts.

We’re pleased to bring state-of-the-art spin galvanizing capabilities to our AZZ Galvanizing-Houston facility.

The Protective Properties of Powder Coating

Rugged and durable powder coating stands up to a vast array of harsh environments – from corrosive conditions to high-impact applications.

AGA Awards: Louis Armstrong New Orleans International Airport

Airports have the potential to offer much more than simply transportation, and the Louis Armstrong New Orleans International Airport (MSY) embodies an innovative and functional approach to air travel.

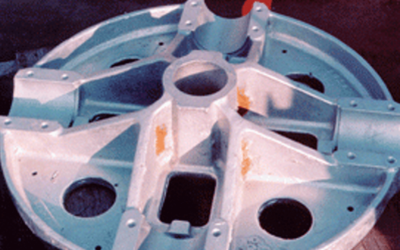

Design Considerations for Hot-Dip Galvanizing: Hole Sizes

When the decision is made to hot-dip galvanize, it is important to consider all aspects of the project, down to the smallest hole.

Galvanizing Applications: Agricultural Equipment

Life in agriculture can be tough. The days are long, the work is difficult, yet rewarding, and there are countless challenges that need to be consistently met head on and overcome. One thing a farmer shouldn’t have to worry about, however, is their equipment, and the best way to protect it is by using galvanized steel.

Utilities are prioritizing modernization efforts to address aging infrastructure and the integration of renewable energy sources

AZZ hot-dip galvanizing and surface technologies provide unmatched protection for critical infrastructure.

Design Considerations for Galvanizing: Fasteners, Bolts and Nails

Perhaps the most critical choice made in the design of connections is how to protect the fasteners from corrosion. Hot-dip galvanizing delivers long-term, maintenance-free corrosion protection in a variety of exposure conditions.

Galvanizing Applications: Fencing

Fences are a staple in many aspects of society and particularly in agriculture, where they’re tasked with the protection of livestock and vulnerable crops or equipment. However, they’re not invincible. Wood rots, steel rusts, and stone cracks.

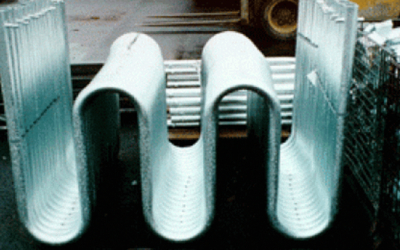

Design Considerations for Galvanizing: Distortion and Warping

With proper consideration and understanding of how the hot-dip galvanizing process affects steel, asymmetrical designs or structures containing sections of unequal thickness can be successfully galvanized, as can fabrications where cold-working techniques (bending, hole-punching, rolling, shearing) are employed.

AZZ plays a critical role in the renewable market

Hot-dip galvanizing protects the integrity of steel exposed continuously to the elements for a lifetime of maintenance-free protection against corrosion.

How Hot-Dip Galvanizing Works

Let’s take a look at the galvanizing process from start to finish.

Design Considerations for Galvanizing: Dissimilar Metals in Contact

When two different metals are in contact in a corrosive environment, one of the metals experiences accelerated galvanic corrosion while the other metal remains galvanically protected.

Design Considerations for Hot-Dip Galvanizing: Dissimilar Steel Chemistries

It is important to understand that the chemical composition of the material being galvanized can affect coating characteristics. However, corrosion protection typically is not affected by these coating characteristic differences.

AGA Awards: The Flying Ox

Adventure Park, located in Pigeon Forge near East Tennessee, is inspired by lumberjacks and the local logging industry. The park has many family friendly attractions like obstacle courses, competitions, a treetop free fall and rides. The Flying Ox is the world’s first cable-to-rail zip line roller coaster. At 1,000 feet long and 80 feet high, the Flying Ox dominates the landscape of Lumberjack Square.

AGA Awards: Large Livestock Trailer

Livestock trailers are necessary in the agriculture and livestock industry. They are used daily to transport animals and can suffer considerable damage from overuse and harsh elements if not properly protected.

Design Considerations for Hot-dip Galvanizing: Cold Worked Steels

Any form of cold-working reduces steel’s ductility. Operations such as punching holes, notching, producing fillets of small radii, shearing, or sharp bending may lead to strain-age embrittlement of susceptible steels.